BORT Logistics Center

⭐Key Features

- •10-meter high bulk storage with 12,000 container locations

- •Double-deep storage configuration

- •Two viaspeed storage and retrieval machines for bulk storage

- •6.4-meter high picking unit with 11,000 storage locations

- •Four additional viaspeed storage and retrieval machines for picking

- •Comprehensive conveyor system integration

- •viad@t Warehouse Management System control

📊Results & Benefits

- ✓Automated storage and retrieval for 23,000 total storage locations

- ✓Integrated bulk storage and picking operations

- ✓Centralized WMS control for entire logistics center

📝Project Overview

Project Overview

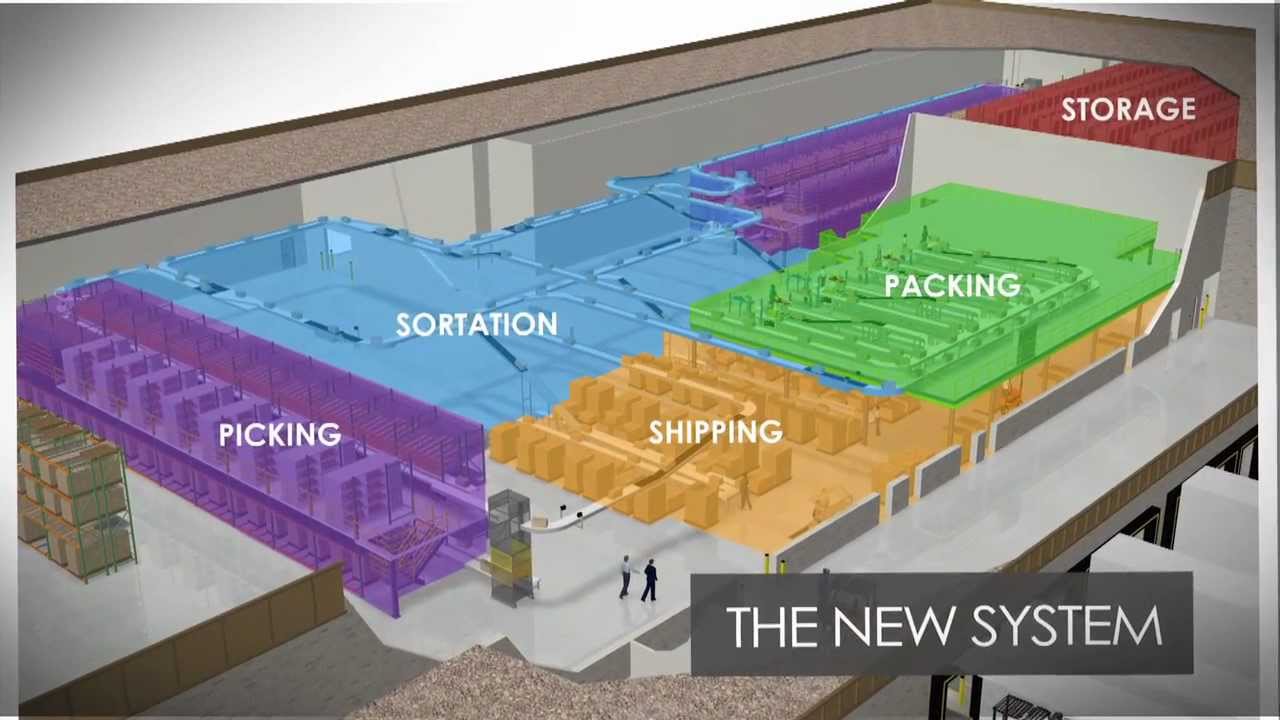

Viastore successfully implemented a comprehensive automated logistics center for BORT, a medical technology manufacturer. This project demonstrates Viastore's expertise in delivering turnkey intralogistics solutions for the healthcare industry, combining advanced storage, picking, and material handling technologies.

The logistics center was designed to meet the specific requirements of medical technology manufacturing and distribution, ensuring efficient handling of components and finished products. The integrated system provides BORT with a modern, automated logistics infrastructure to support their manufacturing operations.

Technical Solution

Bulk Storage System

The center features a 10-meter high bulk storage system with approximately 12,000 container storage locations configured for double-deep storage. This high-density storage solution is served by two viaspeed storage and retrieval machines (SRMs) that efficiently handle container storage and retrieval operations in the bulk storage area.

Dark Warehouse: Fully Automated Warehouse Operations

Vendor: Addverb

Key Features

The bulk storage system's double-deep configuration maximizes storage density while maintaining efficient access to containers. The 12,000-location capacity supports substantial inventory requirements for medical technology manufacturing.

The dedicated picking module with 11,000 storage locations and four viaspeed SRMs ensures high-throughput order fulfillment capabilities. This separation of bulk storage and picking functions optimizes both storage efficiency and order processing speed.

The comprehensive conveyor system integration enables smooth material flow throughout the facility, connecting storage areas with operational zones and supporting efficient logistics workflows.

Results & Benefits

The logistics center provides automated storage and retrieval capabilities for a total of 23,000 storage locations across bulk storage and picking modules. This substantial capacity supports BORT's medical technology manufacturing and distribution requirements.

The integrated system combines bulk storage and picking operations within a unified automated environment, streamlining logistics processes and reducing manual handling requirements.

Centralized control through the viad@t Warehouse Management System ensures coordinated operation of all automated components, providing real-time monitoring and optimization of logistics activities.

System Integrator

Viastore served as the system integrator for this project, leveraging their 40+ years of experience as an international provider of turnkey automated intralogistics solutions. Their core competencies in consulting, system planning, plant engineering, retrofit, and system maintenance were instrumental in the successful implementation of BORT's logistics center. Additionally, Viastore's expertise as a software provider with their viad@t WMS and SAP Logistics Solutions ensured seamless integration and control of the automated systems.

🖼️Project Gallery

🔧Related Technologies (6)

Mid-Load Automated Storage & Retrieval System (AS/RS)

by Conveyco

MINI-LOAD Automated Small-Parts Storage System

byDAMBACH

Intralogistics Innovation Center: Integrated Solutions Showcase

byDaifuku

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

Box-IT: Ergonomic Goods-to-Person Workstation

byAddverb

📚Related Knowledge Articles (2)

Small Load Conveyors

Small load conveyors transport individual items, totes, cartons, and packages through warehouses and distribution centers using belt, roller, or slat systems optimized for lightweight products.

Goods-to-Person Systems

Goods-to-Person (G2P) systems revolutionize warehouse operations by bringing inventory directly to stationary picking stations, eliminating worker travel time and maximizing productivity. These automated systems combine storage, retrieval, and presentation technologies to create highly efficient picking environments.