Box-IT: Ergonomic Goods-to-Person Workstation

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

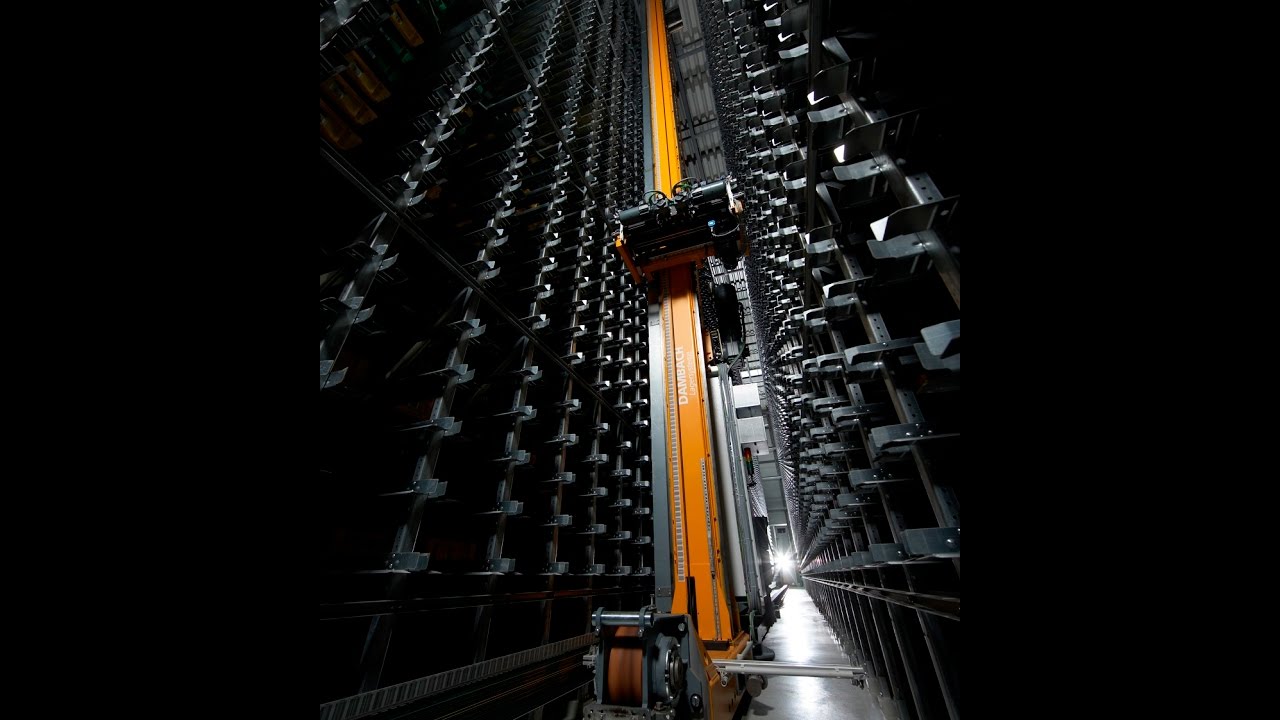

Box-IT represents a human-centric approach to Goods-to-Person (GTP) automation within modern warehouses. While the storage and retrieval of items are handled automatically by an AS/RS, the final step of item selection often remains a manual task. The Box-IT workstation is designed to optimize this human-machine interface. It focuses on creating an efficient, safe, and ergonomic environment for the operator to perform a variety of tasks with maximum accuracy and minimal fatigue. By bringing the items directly to the operator at an optimal working height and angle, and augmenting the process with intuitive visual cues, it transforms a potentially strenuous job into a streamlined, productive operation. This technology is a key component in creating a balanced, high-performance automated warehouse where technology enhances human capability.

How It Works

Core Principles

The core principle is ergonomic Goods-to-Person operation. An automated storage system (like a mini-load AS/RS) delivers totes or bins containing the required items to the Box-IT workstation. The workstation presents the tote to the operator at a fixed, ergonomically optimized angle. Visual systems (lights, projections) guide the operator to the exact pick location and quantity. The operator performs the task (pick, count, audit, etc.), confirms completion, and the system automatically returns the tote and presents the next one.

Key Features & Capabilities

A foundational feature is its ability to seamlessly integrate with Automated Storage and Retrieval Systems, acting as the critical human interface point. Its ergonomic design is centered on an inclined tote presentation at a 35-degree angle, reducing bending and straining. To minimize errors and search time, it is equipped with advanced visual aids including mirrors, LED light systems, and projectors. Beyond just picking, the workstation is versatile, supporting multiple key warehouse processes such as picking, returns, consolidation, decanting, and counting. To fit various operations, it is available in multiple variants tailored for different layouts, applications, and types of goods.

Advantages & Benefits

The workstation is engineered to provide a healthy, safe, and comfortable work environment, which can reduce worker fatigue and injury. It enables high throughput, with a capacity of up to 400 picks per station per hour, by minimizing operator movement and decision time. The combination of ergonomics and visual guidance enhances overall warehouse productivity by speeding up tasks and improving accuracy. Its configurable nature makes it an adaptable solution that can be tailored to diverse warehouse needs and processes.

Implementation Considerations

Effective deployment requires integration with an underlying AS/RS or automated storage system to deliver the totes. Care must be taken to select the appropriate Box-IT variant that matches the physical warehouse layout, the specific application (e.g., piece picking vs. case handling), and the characteristics of the goods being handled.

Use Cases & Applications

Ideal For

Box-IT is ideal for distribution centers, e-commerce fulfillment hubs, and manufacturing warehouses that utilize AS/RS and are looking to optimize their manual pick stations or processing points for ergonomics, speed, and accuracy.

Conclusion

The Box-IT workstation from Addverb exemplifies how thoughtful design can significantly enhance the human element within an automated warehouse. By prioritizing ergonomics, visual guidance, and process versatility, it transforms a GTP station from a simple picking point into a high-performance, multi-function work center. For operations investing in AS/RS, incorporating workstations like Box-IT is crucial to fully realizing the system's potential, ensuring that the automated storage investment is complemented by equally efficient manual interfaces. It represents a smart investment in both productivity and workforce well-being, leading to a more sustainable and effective warehouse operation.

📦Related Projects

Landmark Group Kuwait Fulfillment Center

Landmark Group partnered with Addverb to modernize its Kuwait fulfillment center with robotic sorters and carton shuttles, achieving up to 1,000 sorts per hour for enhanced e-commerce operations.

Addverb 3PL Omnichannel Fulfillment Center

Addverb transformed a 330,000 sq. ft. 3PL facility with integrated fixed and flexible automation, enabling seamless B2B and B2C operations and a dispatch of 100,000 pieces daily.

Dongfeng Motor R&D Center Smart Logistics Warehouse

A compact 470㎡ intelligent warehouse with 15-level high-density storage supporting 10,000+ SKUs for automotive R&D supply chain optimization.