Mid-Load Automated Storage & Retrieval System (AS/RS)

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

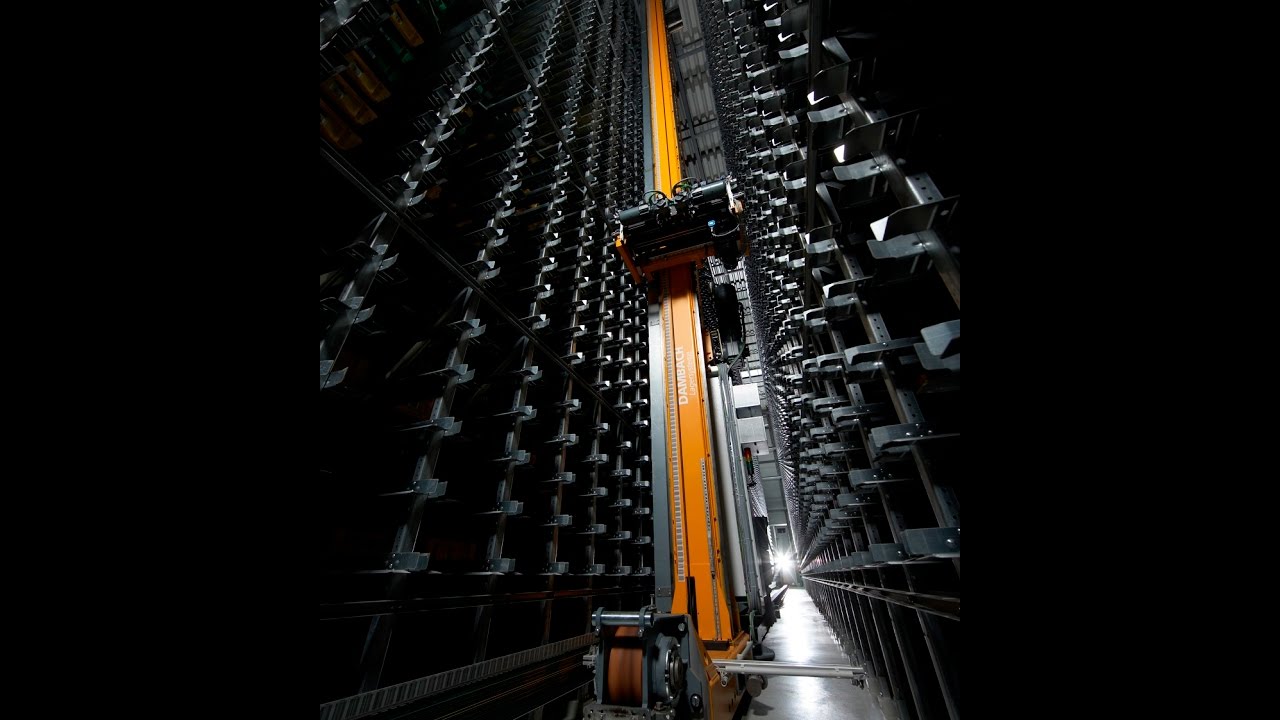

The Mid-Load Automated Storage and Retrieval System (AS/RS) is designed to address a specific niche in warehouse automation: the storage of medium-weight or awkwardly sized loads that fall between the typical capacities of mini-load systems (for small parts) and unit load systems (for full pallets). This technology provides a high-density, fully automated storage solution for items like individual cases, bins, specialized pallets, tooling, and other containers that are too heavy or large for a mini-load yet don't require a full unit load crane. By filling this gap, it offers a space-efficient alternative to static shelving or racking for a wide variety of inventory types.

How It Works

Core Principles

The core principle is similar to other AS/RS technologies: a computer-controlled machine (a mid-load crane or shuttle) moves within an aisle of high-rise storage racking to automatically store and retrieve loads from specific locations. The system is optimized for loads that are heavier than typical tote bins but lighter than full pallet loads, often in the several hundred kilogram range.

Key Features & Capabilities

Versatile Load Handling: A defining feature is its ability to accommodate a "wide range of cases, pallets, specialized pallets and tooling, bins, and much more." This is achieved through customizable load-handling attachments on the retrieval machine.

Extreme Space Savings: The system is engineered for vertical density, claiming to save "over 85% of floor space" compared to traditional storage methods like pallet racking or shelving, by utilizing the full clear height of the facility.

Modular and Reconfigurable Design: Unlike monolithic systems, this AS/RS is built with modular components. This allows the system to be "rapidly deployed, moved, grown, and reconfigured" as business needs evolve, offering significant long-term flexibility.

Advantages & Benefits

The most significant benefit is the dramatic reduction in the facility's storage footprint, which can free up space for other value-adding activities like production or order fulfillment. Automation increases inventory accuracy to near 100%, reduces labor costs associated with manual put-away and picking, and improves workplace safety by removing personnel from high-reach forklift operations. The system's flexibility and scalability protect the investment against future changes in product mix or volume.

Implementation Considerations

Implementing a Mid-Load AS/RS requires a detailed analysis of all intended load types (dimensions, weight, center of gravity) to ensure compatibility with the system's handling mechanisms. The facility must have adequate ceiling height to justify the vertical storage. The initial investment is substantial, so a solid business case focusing on space savings, labor reduction, and throughput improvements is essential. Integration with the host Warehouse Management System (WMS) is critical for efficient operation.

Use Cases & Applications

Ideal For

This system is ideal for manufacturing facilities, distribution centers, or service parts operations that handle a large number of medium-weight, high-SKU-count items that are currently stored inefficiently on shelving or in wide aisles of pallet racking.

Performance Metrics

The key performance metric is the space savings claim of "over 85% of floor space." Other metrics include throughput (storage/retrieval cycles per hour), system availability (uptime), and storage density (units per square meter/foot). The system's value is also measured in reduced labor hours, improved inventory accuracy, and faster order cycle times.

Conclusion

The Mid-Load AS/RS is a powerful solution for businesses seeking to maximize storage density and operational efficiency for a diverse range of medium-weight inventory. By bridging the gap between smaller and larger automated systems, it offers a tailored, high-performance option. For companies facing space constraints, labor challenges, or the need for greater inventory control, investing in a modular Mid-Load AS/RS from a provider like Conveyco can deliver transformative savings and flexibility, making it a strategic asset for modern, efficient logistics operations.