MINI-LOAD Automated Small-Parts Storage System

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

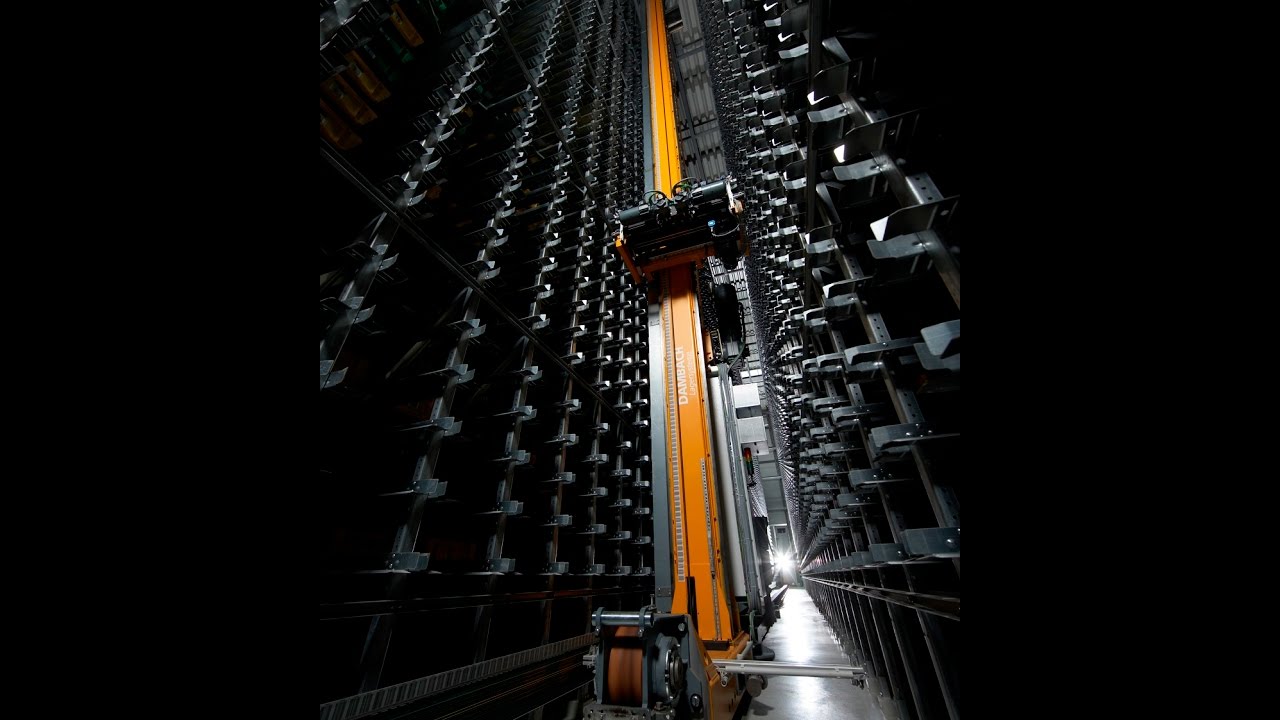

The DAMBACH MINI-LOAD system is a classic and highly efficient form of Automated Storage and Retrieval System (AS/RS) specifically designed for handling small, lightweight unit loads. These loads are typically stored in standardized plastic totes, trays, or other specialized containers. The system is built around automated stacker cranes that operate within narrow aisles of high-rise storage racking, reaching heights of up to 27 meters. This technology is a cornerstone of high-density, high-throughput storage for industries with a large number of SKUs that are physically small but may be high in value or require fast access, such as in electronics, automotive, pharmaceuticals, and spare parts logistics.

How It Works

Core Principles

The core principle is the use of a computer-controlled, rail-guided stacker crane to automatically store and retrieve containers from specific locations within a dense storage matrix. The system optimizes space by utilizing the full clear height of the building and minimizing aisle width, while speed is achieved through the rapid horizontal and vertical movement of the crane.

Key Features & Capabilities

High-Bay Operation up to 27m: A defining feature is its ability to operate efficiently at very great heights, allowing facilities to maximize their cubic storage space and achieve exceptional storage density per square meter of floor space.

High Throughput Performance: The stacker cranes are engineered for speed and acceleration, enabling high numbers of dual-command (store and retrieve) cycles per hour. This makes the system suitable for dynamic environments with frequent transactions.

Versatile Load Handling: The system's flexibility comes from its support for various load-handling devices. Telescopic forks can handle standard trays, while box grabs or other special attachments allow the storage of non-standard or specially designed containers, catering to specific industry needs.

Durable and Robust Construction: Built for industrial 24/7 environments, the system emphasizes durable construction. This ensures long-term reliability and minimal downtime, which is critical for operations where the storage system is the backbone of material flow.

Advantages & Benefits

The primary advantage is the immense space savings and increased storage capacity within a given footprint. Automation drastically improves inventory accuracy, reduces labor costs associated with manual picking/put-away, and enhances workplace safety by removing personnel from high-reach forklift operations. The high throughput ensures fast response times for order fulfillment or production line feeding. The ability to handle special containers allows for integration into specialized processes like clean rooms or tool management.

Implementation Considerations

Implementing a high-bay MINI-LOAD system requires a building with sufficient clear height and a structure capable of supporting the dynamic loads of the racking and moving cranes. The choice of container (tote/tray) and handling device must be finalized early in the design process. The system represents a significant capital investment, so a clear business case based on space savings, labor efficiency, and throughput requirements is essential. Integration with a WMS/WCS is required for optimal performance.

Use Cases & Applications

Ideal For

This system is ideal for any operation with a high volume of small parts, tools, or components that require dense, organized, and fast-access storage. It is common in manufacturing support, distribution centers for spare parts, and as a buffer storage system in automated order fulfillment.

Performance Metrics

Key metrics include throughput (cycles per hour per aisle), storage density (number of storage locations per m²), and system availability (uptime). The "high throughput rates" claim indicates performance designed for demanding applications. The system's value is also measured in reduced operational footprint, improved pick rates, and lower error rates compared to manual shelving.

Conclusion

The DAMBACH MINI-LOAD AS/RS is a proven, high-performance solution for automating small-parts storage. Its combination of vertical density, high speed, and handling flexibility makes it a powerful tool for optimizing space and logistics efficiency. For companies struggling with sprawling small-parts storage, inaccurate inventory, or slow order processing times, investing in a robust mini-load system can provide a transformative improvement in operational control, capacity, and cost-effectiveness.

📦Related Projects

DAMBACH MINI-LOAD Automated Small Parts Storage System

The DAMBACH MINI-LOAD system is an automated storage and retrieval machine for small parts, achieving heights up to 27 meters and high throughput for container and carton storage.

LIEKEN High Bay Cold Store for Baked Goods

A high bay cold store for bread and baked goods with a capacity of 6,000 pallets at -24°C, using DAMBACH Storage and Retrieval Machines to achieve 4,296 pallet movements daily.

Dongfeng Motor R&D Center Smart Logistics Warehouse

A compact 470㎡ intelligent warehouse with 15-level high-density storage supporting 10,000+ SKUs for automotive R&D supply chain optimization.