Our Curated Projects

29 projects

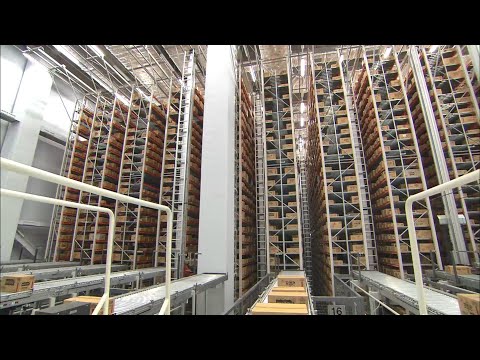

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Lao Gan Ma Guiyang Guizhou Production Warehouse

The iconic Chinese chili sauce brand automated its production logistics with a large-scale Unit Load AS/RS, palletizing robots, and STVs to connect 7 lines across 6 factories, achieving high inbound/outbound throughput.

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

Vinamilk Saigon Dairy Factory Cold Storage Warehouse

Vietnam's leading dairy producer implemented a cold-environment Automated Storage and Retrieval System (AS/RS) that quadrupled storage capacity while enhancing efficiency and quality control in its logistics operations.

Snack Brands Australia Sydney Distribution Center

Snack Brands consolidated two warehouses into a 30,255 sqm facility with Daifuku's high-bay AS/RS, achieving fully automated distribution for iconic snack brands.

Peterbilt - ASRS Aisle 4 Retrofit Project

Peterbilt retrofitted ASRS Aisle 4 to increase storage capacity for large integral cab sleeper units, completed 6 weeks early with no production disruptions by Daifuku.

NEXT Doncaster Furniture Distribution Center

NEXT implemented Körber's automated pallet handling solution with RGVs and ASRS across two warehouses for fast furniture and goods movement with 77,000 pallet locations.

Roark - Aerospace Tool & Die Automated Storage System

Roark implemented Bastian Solutions' automated storage and retrieval system for aerospace tools and dies, replacing manual pallet storage with organized ASRS for complex sheet metal fabrication.

DAMBACH MINI-LOAD Automated Small Parts Storage System

The DAMBACH MINI-LOAD system is an automated storage and retrieval machine for small parts, achieving heights up to 27 meters and high throughput for container and carton storage.

LIEKEN High Bay Cold Store for Baked Goods

A high bay cold store for bread and baked goods with a capacity of 6,000 pallets at -24°C, using DAMBACH Storage and Retrieval Machines to achieve 4,296 pallet movements daily.

Daifuku Intralogistics India Hyderabad Manufacturing Facility

Daifuku Intralogistics India launched its first-ever 30-meter-tall stacker crane manufactured entirely in India, representing a major milestone for the Make in India initiative and local advanced intralogistics production.

V-ZUG Kühltechnik Sulgen Refrigerator Factory

V-ZUG built a new refrigerator factory with GEBHARDT's automated logistics systems, achieving production of one refrigerator per minute with significant automation.

Hirschmann Automotive Rankweil Production Logistics

Hirschmann Automotive implemented a fully automated production logistics system with Servus Intralogistics, seamlessly connecting warehouse and production with 46 transport robots.