Intralogistics Innovation Center: Integrated Solutions Showcase

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

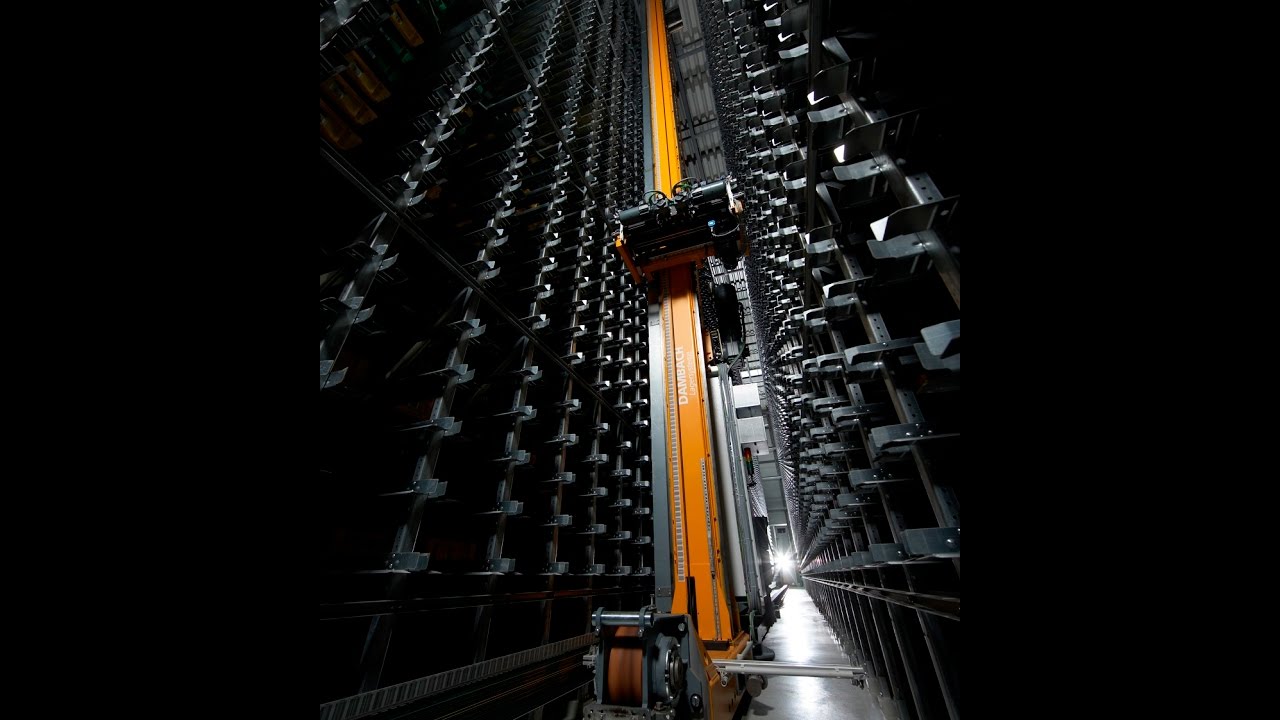

The Intralogistics Innovation Center is not a single technology, but a comprehensive demonstration and validation environment for a portfolio of advanced warehouse automation technologies. Operated by Daifuku, a global leader in material handling, this facility serves as a living lab and showroom where potential clients can experience integrated solutions firsthand. The center showcases how disparate technologies—such as Automated Storage and Retrieval Systems (AS/RS), high-speed sortation, and robotic depalletizing—can be combined into a cohesive, high-performance system. A core philosophy emphasized is the rejection of one-size-fits-all solutions in favor of a consultative, custom-engineered approach tailored to each client's specific needs, validated through cutting-edge digital tools.

How It Works

Core Principles

The core principle is solution validation and demonstration through integration and simulation. The center physically houses operational examples of key technologies. More importantly, it employs a multi-stage validation process using simulation and digital twin emulations. This allows engineers to model, test, and optimize a complete system in a virtual environment that mirrors real-world conditions before any physical installation begins.

Key Features & Capabilities

Digital Twin & Simulation-Driven Design: This is a foundational capability. It allows for risk-free testing of system logic, throughput, and bottleneck identification under simulated peak loads and failure scenarios, leading to more robust and reliable final designs.

Custom-Fit Solution Curation: The center embodies a philosophy of deep customer analysis. Solutions are "curated" based on a detailed understanding of the client's unique products, operational flow, and existing infrastructure, ensuring the proposed automation delivers impactful, relevant results.

Wide-Range Product Handling (AS-35 Sorter): The showcased AS/RS system is noted for its ability to handle one of the widest product ranges in the industry, including totes, cartons, trays, mailers, and polybags, often within the same system, providing exceptional flexibility.

Compact Robotic Depalletizing (RDS): The latest generation RDS system emphasizes an industry-leading compact footprint. This reduces the floor space required for the depalletizing function, offering greater flexibility in warehouse layout and potential installation cost savings.

Advantages & Benefits

The primary benefit is de-risking large-scale automation investments. By visualizing and testing a system virtually, clients gain confidence in the design's performance and ROI before committing to construction. The tailored approach ensures the solution aligns perfectly with business needs, avoiding the pitfalls of under or over-engineering. Demonstrating maintenance-friendly designs (like the calibration-free sorter) highlights long-term operational reliability and lower total cost of ownership.

Implementation Considerations

Engaging with this level of system integration requires a significant investment of time and resources in the planning and design phase. The custom nature means solutions are not off-the-shelf and have longer lead times for design and implementation. Clients must be prepared to share detailed operational data and business goals to enable the effective custom design and simulation process.

Use Cases & Applications

Ideal For

This approach is ideal for large-scale, greenfield warehouse or distribution center projects, or major brownfield retrofits, where the automation investment is substantial and the operational complexity is high. It is also valuable for companies with unique or challenging product handling requirements.

Performance Metrics

While specific throughput numbers are not given, the center demonstrates technologies aimed at "best-in-class precision," "efficiency," and handling under "high volume... conditions." The validation process itself is a key performance indicator, ensuring systems are designed to meet targeted service levels and throughput goals before installation. The compact footprint of the RDS system is a tangible metric for space savings.

Conclusion

Daifuku's Intralogistics Innovation Center represents the forefront of a systems-engineering approach to warehouse automation. It moves beyond selling discrete equipment to offering validated, integrated solutions that are custom-built to solve specific business challenges. For companies contemplating a transformative automation project, engaging with a partner that utilizes such a center and a digital twin-driven methodology significantly reduces risk and increases the likelihood of a successful implementation that delivers on its promised efficiency, flexibility, and return on investment.

📦Related Projects

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.