Goods-to-Person Systems

Goods-to-Person (G2P) systems revolutionize warehouse operations by bringing inventory directly to stationary picking stations, eliminating worker travel time and maximizing productivity. These automated systems combine storage, retrieval, and presentation technologies to create highly efficient picking environments.

Core Technology

- • Speech recognition software

- • Text-to-speech engines

- • Wireless headset systems

- • Voice command processing

- • Real-time communication

Hardware Components

- • Wireless headsets

- • Wearable computers

- • Noise-canceling microphones

- • Mobile devices

- • Network infrastructure

Applications

- • Order fulfillment

- • Multi-SKU picking

- • Cold storage operations

- • Retail distribution

- • E-commerce fulfillment

Benefits

- • Hands-free operation

- • Eyes-free navigation

- • Improved accuracy

- • Faster training

- • Better ergonomics

Implementation

- • Voice template creation

- • WMS integration

- • Worker training programs

- • Network setup

- • Performance monitoring

Considerations

- • Noise level control

- • Accent adaptation

- • System reliability

- • Battery management

- • Vocabulary maintenance

Key Performance Metrics

The Intelligence Behind Automated Presentation

Modern G2P systems leverage sophisticated algorithmic intelligence to orchestrate the complex choreography of inventory movement and presentation. The system's brain continuously analyzes order patterns, inventory turnover rates, and operational constraints to determine the optimal sequence for item retrieval and presentation. This intelligence extends beyond simple pick optimization to include predictive slotting strategies that position frequently ordered items for faster access, and dynamic batching algorithms that intelligently combine multiple orders to maximize picking efficiency.

The automated storage infrastructure forms the backbone of these systems, utilizing high-density storage configurations that can accommodate thousands or even hundreds of thousands of SKUs within an extremely compact footprint. Whether through robotic shuttles navigating multi-level storage grids, carousel systems rotating inventory to picking positions, or vertical lift modules delivering entire storage trays to workers, the fundamental principle remains consistent: maximize storage density while ensuring rapid item access. This density advantage allows facilities to store significantly more inventory in the same space, or achieve the same storage capacity in a much smaller facility.

Real-time inventory synchronization ensures that every item movement is precisely tracked, providing unprecedented visibility into inventory levels, location accuracy, and order status. This level of control enables operations to maintain inventory accuracy rates exceeding 99.5%, far surpassing traditional manual picking methods. The system's ability to track every item movement also provides valuable data for continuous optimization of slotting strategies and operational procedures, creating a self-improving system that becomes more efficient over time.

Technology Variants and System Types

Shuttle-based systems represent one of the most versatile G2P technologies, utilizing automated vehicles that travel along rails within storage structures to retrieve and deliver totes or bins to picking stations. These systems can be configured for pallet-level storage in high-bay warehouses or tote-level storage in smaller facilities, with throughput capabilities ranging from 200 to over 1,000 picks per hour depending on system design and product characteristics. The modular nature of shuttle systems allows for incremental capacity expansion as business requirements grow, providing scalability that matches investment to actual demand.

Carousel systems offer a different approach, rotating inventory on horizontal or vertical tracks to bring items to stationary picking positions. Horizontal carousels excel in batch picking applications where multiple orders can be processed simultaneously, while vertical carousels maximize space utilization in facilities with limited floor space but adequate ceiling height. These systems typically deliver 300-600 picks per hour and are particularly effective for operations with moderate SKU counts and relatively consistent item sizes.

Vertical Lift Modules represent a highly space-efficient G2P solution, using automated extractors to retrieve storage trays from vertical towers and present them at ergonomic working heights. VLMs can achieve storage densities 60-80% higher than traditional shelving while providing picking rates of 150-350 picks per hour. The enclosed design protects inventory from dust and damage while providing security for high-value items, making VLMs particularly popular in pharmaceutical, electronics, and precision parts applications.

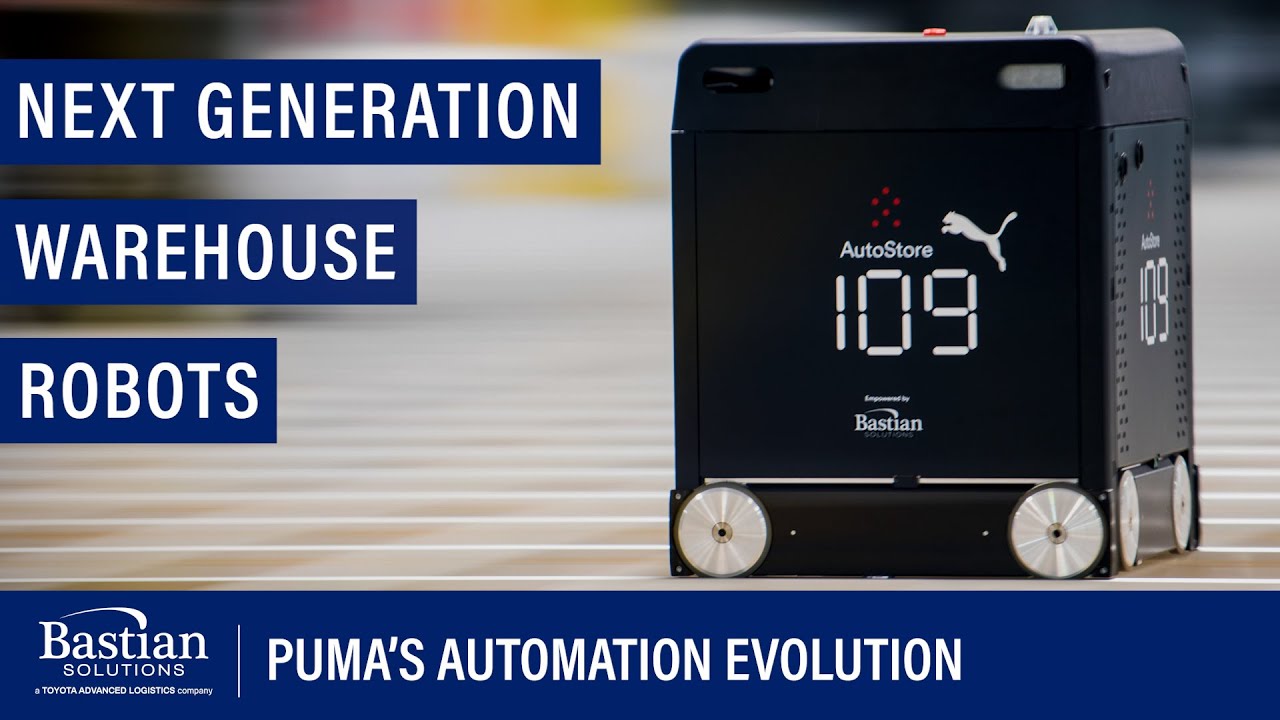

Cube-based systems like AutoStore have revolutionized high-density storage by stacking bins in a grid structure with robots traveling on top to retrieve requested items. These systems can achieve storage densities 3-4 times higher than traditional shelving while maintaining impressive picking rates of 100-500 picks per hour per port. The modular grid design allows systems to be expanded incrementally and even reconfigured to accommodate changing facility layouts, providing exceptional flexibility for growing operations.

Goods-to-Person System: Warehouse Automation Solution

Vendor: Others

Operational Excellence and Performance Optimization

The performance advantages of G2P systems extend far beyond simple productivity metrics. By eliminating worker travel time, these systems can increase picking productivity by 300-500% compared to traditional manual methods. Workers at G2P stations can process 200-1,000 picks per hour depending on system type and product characteristics, compared to 60-120 picks per hour typical of manual cart picking operations. This dramatic productivity improvement allows facilities to process significantly higher order volumes with the same or fewer workers.

Accuracy improvements represent another critical benefit, with G2P systems routinely achieving 99.5-99.9% picking accuracy through multiple verification mechanisms. Pick-to-light indicators guide workers to the correct items and quantities, while weight verification systems confirm that the correct number of items has been picked. Barcode scanning provides additional confirmation of product identity, creating multiple checkpoints that virtually eliminate picking errors. This accuracy improvement reduces costs associated with returns, customer dissatisfaction, and correction activities while improving overall service quality.

The ergonomic benefits of G2P systems significantly reduce workplace injuries and improve employee satisfaction. By bringing items to workers at optimal working heights and eliminating the need for reaching, bending, and walking, these systems reduce physical strain by 85-95% compared to traditional picking methods. This reduction in physical demands not only improves worker safety and reduces workers' compensation costs but also makes warehouse work accessible to a broader range of employees and extends productive working careers.

Economic Analysis and Investment Justification

The capital investment required for G2P systems varies significantly based on technology type, capacity requirements, and integration complexity. Basic carousel or VLM systems may require investments of $150,000-500,000 per module, while comprehensive shuttle-based or cube storage systems can range from $1,000,000 to $10,000,000 or more for large installations. Despite these substantial upfront costs, the combination of labor savings, space efficiency, and accuracy improvements typically delivers payback periods of 2-4 years for high-volume operations.

Labor cost reduction represents the primary economic driver for most G2P implementations. By increasing picking productivity by 300-500%, systems can reduce direct picking labor by 50-80% while simultaneously increasing throughput. For operations processing 1,000 or more picks per day, annual labor savings of $200,000-800,000 are common, providing compelling economics even for mid-sized operations. The consistency and predictability of automated performance also reduces the need for temporary labor during peak periods, further improving cost structure and operational reliability.

Space efficiency improvements deliver substantial value beyond direct cost savings. G2P systems typically achieve 60-80% better space utilization than traditional shelving, allowing facilities to store more inventory in existing space or achieve the same storage capacity in a smaller facility. For operations facing facility expansion decisions, the ability to defer or eliminate building expansion can represent savings of millions of dollars. Even for operations not facing immediate space constraints, improved space utilization provides valuable flexibility for future growth and operational changes.

Box-IT: Ergonomic Goods-to-Person Workstation

Vendor: Addverb

Integration Challenges and Success Factors

Successful G2P implementation requires careful integration with existing warehouse management systems and operational processes. The WMS must provide real-time picking instructions to the G2P system while receiving immediate feedback on task completion, inventory adjustments, and exception conditions. This bidirectional communication ensures that warehouse management maintains accurate visibility into automated operations while providing the G2P system with the information needed to optimize performance. Many implementations require WMS upgrades or modifications to support the real-time communication and advanced functionality required by G2P systems.

Inventory slotting optimization becomes even more critical in G2P environments where the system's performance depends heavily on intelligent item placement. Fast-moving items should be positioned for rapid access, while slower-moving items can be stored in less accessible locations. The system must continuously analyze picking patterns and adjust slotting strategies to maintain optimal performance as product mix and demand patterns evolve. Many operations employ dedicated slotting software that integrates with both the WMS and G2P control system to automate this optimization process.

Change management represents a critical success factor often underestimated in G2P implementations. Workers accustomed to traditional picking methods must adapt to new workflows, technologies, and performance expectations. Comprehensive training programs should address not only the mechanical operation of G2P systems but also the reasoning behind new processes and the benefits they deliver. Many successful implementations involve workers in system design and optimization, creating ownership and engagement that accelerates adoption and drives continuous improvement.

Application Scenarios and Industry Fit

E-commerce fulfillment operations represent ideal applications for G2P technology, with their high SKU counts, small order sizes, and intense pressure for rapid fulfillment. The ability to process 500-1,000 picks per hour per operator enables e-commerce operations to meet aggressive delivery commitments while managing labor costs. The accuracy improvements delivered by G2P systems reduce costly shipping errors and returns, while the space efficiency allows operations to locate fulfillment centers closer to customers, reducing transportation costs and delivery times.

Pharmaceutical and healthcare distribution operations benefit particularly from the security, accuracy, and traceability capabilities of G2P systems. The enclosed storage environment protects high-value medications from theft and environmental damage, while multiple verification checkpoints ensure accurate dispensing of prescription medications. The system's ability to track every item movement provides the detailed audit trails required by regulatory agencies, while lot tracking and expiration date management capabilities ensure product quality and patient safety.

Automotive parts distribution operations leverage G2P technology to manage the extreme SKU complexity characteristic of aftermarket parts operations. With 50,000 or more active SKUs common in automotive distribution, the high-density storage capabilities of G2P systems provide essential space efficiency. The accuracy improvements reduce costly shipping errors that can result in vehicle downtime and customer dissatisfaction, while the productivity gains enable operations to meet the rapid delivery requirements of repair shops and dealerships.

Future Evolution and Technology Trends

The integration of artificial intelligence and machine learning technologies will further enhance G2P system capabilities in coming years. Predictive analytics will enable systems to anticipate demand patterns and pre-position inventory for faster fulfillment, while autonomous optimization algorithms will continuously refine slotting strategies and picking sequences without human intervention. Machine learning models will identify patterns in operational data that humans might miss, uncovering opportunities for performance improvement and efficiency gains.

Robotics integration will expand the capabilities of G2P systems beyond simple item presentation. Collaborative robots working alongside human pickers will handle repetitive or physically demanding tasks, while vision-guided picking systems will automate item selection for products with consistent characteristics. The combination of G2P presentation with robotic manipulation will create hybrid systems that deliver even higher productivity while further reducing physical demands on human workers.

The emergence of micro-fulfillment centers in urban areas will drive demand for compact, high-performance G2P systems that can operate in smaller facilities closer to customers. These systems must deliver the productivity and accuracy of larger installations while fitting within the space and infrastructure constraints of urban locations. Modular system designs and rapid deployment capabilities will enable retailers and logistics providers to quickly establish fulfillment capacity in new markets, supporting the continued growth of same-day and next-day delivery services.

Strategic Implementation Considerations

Organizations considering G2P technology should begin with comprehensive feasibility analysis that evaluates current operations, product characteristics, and facility constraints. Detailed data on order profiles, SKU velocity, item dimensions, and picking volumes provides the foundation for accurate system sizing and performance projections. Simulation modeling helps validate design assumptions and identify potential bottlenecks before committing to equipment purchases, reducing implementation risk and improving confidence in projected outcomes.

Vendor selection requires careful evaluation of technical capabilities, implementation experience, and long-term support commitments. Site visits to existing installations provide valuable insights into system performance and vendor support quality, while reference checks with current customers reveal potential issues and best practices. The quality of vendor partnership significantly impacts long-term success, as ongoing optimization and system evolution require sustained collaboration and support.

Phased implementation approaches reduce risk and allow organizations to develop operational expertise before full-scale deployment. Starting with a single G2P module handling a subset of products enables teams to refine processes, train personnel, and validate performance assumptions before expanding to additional capacity. This incremental approach also provides flexibility to adjust system design based on early operational experience, ensuring that subsequent phases benefit from lessons learned during initial deployment.

The future of warehouse picking is increasingly automated, with Goods-to-Person systems playing a central role in enabling the speed, accuracy, and efficiency that modern commerce demands. Success requires careful planning, realistic expectations, and commitment to ongoing optimization, but the operational and economic benefits make G2P technology an increasingly compelling choice for organizations seeking to build competitive advantage through warehouse automation. As technology continues to advance and costs decline, G2P systems will become accessible to a broader range of operations, transforming warehouse picking across industries and operational scales.

🔧Related Technologies (6)

Vertical Carousel System: Automated Storage Solution

byJungheinrich

Mini-Load AS/RS: Automated Storage and Retrieval for Small Loads

byDaifuku

Dematic Goods-to-Person AMR: Next-Generation Autonomous Mobile Robot

byDematic

Goods-to-Person System: Warehouse Automation Solution

byOthers

Box-IT: Ergonomic Goods-to-Person Workstation

byAddverb

Brightpick Retriever: Goods-to-Person Robots for Order Picking and Replenishment

byBrightpick

📚Related Picking Topics

About This Topic

📁Related Projects(6)

DHL Supply Chain Greater Poland E-commerce Hub

Element Logic

FIEGE Apfelstädt Logistics Center AutoStore System

Element Logic

PUMA Indianapolis Pandemic-Resilient Distribution Center

Bastian Solutions

PUMA Indianapolis East Coast Distribution Center

Bastian Solutions

Cutter & Buck Seattle Apparel Fulfillment Center

Kardex

Alza Prague High-Throughput Fulfillment Center

Element Logic