Storage

Storage is the warehouse process of holding inventory in organized locations until needed, balancing space utilization, accessibility, and inventory control to support efficient operations.

🧠 Storage Operations Overview

Interactive overview of storage systems and strategies - click to explore each category

Racking Systems

Automated Storage

Slotting & Optimization

Space Management

Process Flow and Business Characteristics

Putaway operations begin after products are received and inspected, with the warehouse management system directing workers to place items in assigned storage locations. The system considers product velocity (how frequently items are picked), physical characteristics (dimensions, weight, stackability), special requirements (temperature control, hazmat segregation, security), and available capacity when making assignments. Directed putaway provides specific location assignments, while operator-directed putaway allows workers to choose from suggested zones based on their judgment and current conditions.

Storage location types serve different purposes within the warehouse. Reserve storage in high-density systems (pallet racking, drive-in racks, AS/RS) holds bulk inventory of slower-moving items, prioritizing space efficiency over accessibility. Forward pick locations in easily accessible areas (flow racks, shelving, carton flow) hold smaller quantities of fast-moving items near packing stations, prioritizing accessibility over density. Specialized storage (cold rooms, hazmat areas, secure cages, high-value vaults) accommodates products with special environmental, safety, or security requirements.

Slotting strategies assign products to storage locations based on multiple factors. Velocity-based slotting places fast-moving items (A items) in the most accessible locations, medium-velocity items (B items) in standard locations, and slow-moving items (C items) in less accessible positions. This ABC analysis typically shows that 20% of SKUs generate 80% of picks, making their placement critical for efficiency. Cube-based slotting matches product size to location capacity, minimizing wasted space. Affinity slotting places items frequently ordered together near each other, reducing pick travel.

Inventory control processes maintain accurate records of what is stored where and in what quantities. Cycle counting programs verify physical inventory against system records on rotating schedules, with high-value and high-velocity items counted more frequently. Location audits confirm that products in locations match system records, catching errors from mispicks or incorrect putaway. Lot tracking and serial number management support traceability requirements for regulated products, enabling recalls or quality investigations when needed.

Space management monitors utilization and plans for growth or seasonal peaks. Capacity planning forecasts storage requirements based on sales projections, lead times, and inventory policies. Seasonal adjustments accommodate predictable volume fluctuations, while overflow strategies (temporary storage, third-party warehousing) address unexpected capacity constraints. Layout optimization periodically reconfigures storage areas to match changing product mixes or operational requirements.

Automation Technologies

Warehouse management systems (WMS) orchestrate all storage activities, directing putaway, tracking locations, optimizing slotting, and maintaining inventory accuracy. Modern WMS platforms use algorithms to assign storage locations based on product characteristics and operational rules, real-time inventory tracking to maintain accurate available-to-promise quantities, and analytics to identify slotting opportunities or capacity constraints. Mobile devices with barcode scanning enable workers to execute system-directed tasks while confirming actions through scan verification.

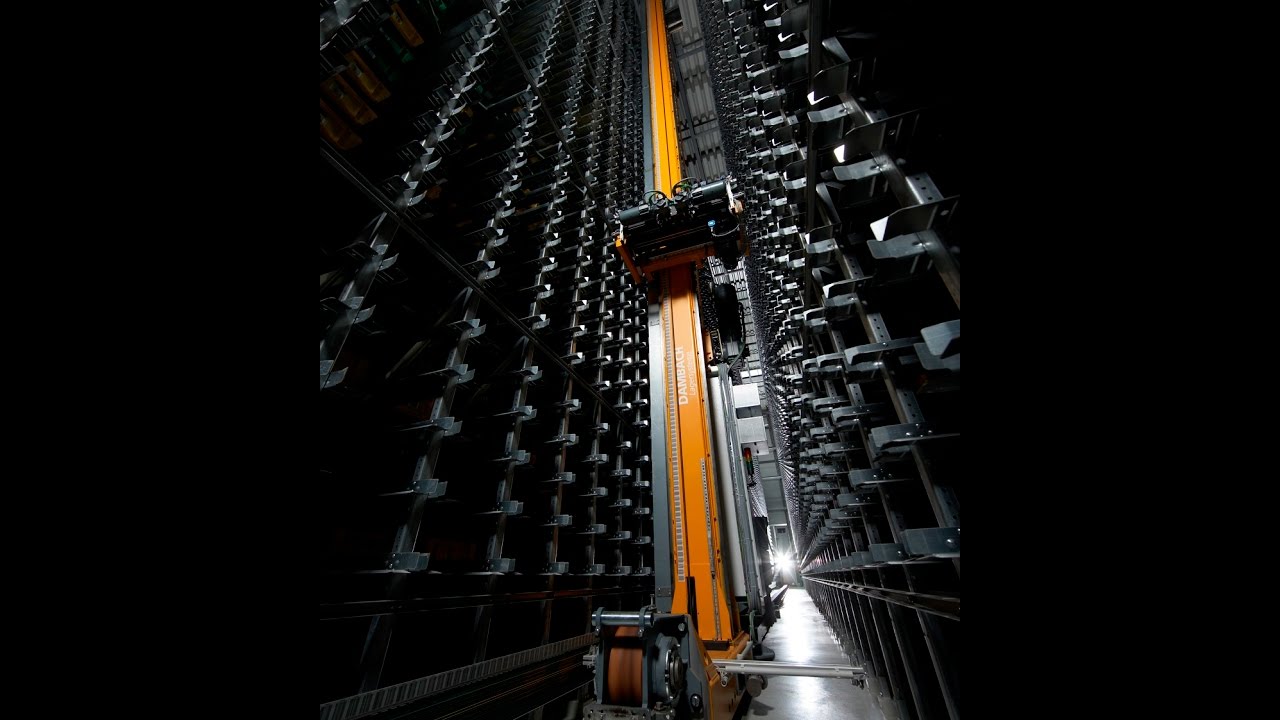

Automated storage and retrieval systems (AS/RS) maximize storage density while improving accuracy and throughput. Unit load AS/RS handles full pallets in narrow aisles reaching 100+ feet high, achieving 80-90% space utilization. Mini-load AS/RS manages totes or cartons for piece-picking operations, delivering 3-5x productivity improvements over manual picking. Shuttle systems provide scalable capacity by adding autonomous vehicles as volume grows. These systems eliminate manual putaway and retrieval labor while maintaining 99.9%+ inventory accuracy through automated tracking.

Vertical storage solutions including vertical lift modules (VLM) and vertical carousels maximize use of ceiling height in compact footprints. A single VLM occupying 15-30 square feet can replace 200-400 square feet of shelving, freeing valuable floor space. These systems automatically deliver trays or carriers to ergonomic access openings, eliminating worker travel and improving productivity by 2-3x. Enclosed designs protect products from dust and damage while providing secure storage for high-value items.

Mobile racking systems eliminate fixed aisles by mounting racks on motorized bases that move along floor rails, achieving 80-90% space utilization while maintaining full selectivity. The system creates aisles on demand where needed, enabling facilities to store 2x more inventory in the same footprint compared to conventional racking. This technology is particularly valuable in cold storage where reducing building volume lowers energy costs by 30-50%, or in expensive real estate where space efficiency justifies the investment.

Slotting optimization software analyzes order history, product characteristics, and facility layout to recommend optimal storage assignments. These tools identify velocity changes requiring slotting adjustments, affinity relationships between products, and space utilization opportunities from better product-to-location matching. Simulation capabilities model different slotting scenarios before implementation, quantifying expected benefits. Dynamic slotting continuously adjusts assignments as conditions change, maintaining optimal placement without manual intervention.

RFID and IoT sensors provide real-time visibility into inventory locations and conditions. RFID tags on products or storage containers enable touchless inventory tracking where readers automatically detect items without manual scanning. Environmental sensors monitor temperature, humidity, and other conditions in storage areas, alerting staff to issues that could affect product quality. Location sensors verify that products are in assigned positions, catching putaway errors immediately rather than discovering them during picking.

Key Performance Indicators

Space utilization measures the percentage of available storage capacity in use, with targets typically 70-85% to balance efficiency against flexibility for growth. Cube utilization (percentage of location volume occupied) provides more granular insight than simple position counts, identifying wasted space from partially filled locations. Utilization by zone and location type reveals constraints requiring attention, while seasonal peak utilization ensures adequate capacity for maximum inventory levels.

Inventory accuracy tracks how well system records match physical inventory, with targets of 99%+ for automated systems and 95-98% for manual operations. Cycle count accuracy measures the percentage of counts matching system records on first count, while location accuracy verifies that products in locations match system assignments. Root cause analysis of discrepancies identifies whether errors occur during putaway, picking, or system transactions, enabling targeted improvements.

Slotting effectiveness measures how well product placement matches velocity, typically tracking the percentage of picks occurring from A locations (target 80%+). Pick travel distance per order line indicates whether fast-moving items are properly positioned near packing areas. Replenishment frequency for forward pick locations suggests whether quantities are appropriately sized. Periodic slotting analysis (quarterly or semi-annually) identifies opportunities for improvement as velocity patterns change.

Putaway productivity measures pallets or units stored per labor hour, varying by product type and storage method. Pallet putaway typically achieves 15-25 pallets per hour for conventional racking, while case putaway averages 100-200 cases per hour depending on travel distance and location accessibility. Automation can improve productivity by 50-70%, while process improvements (better slotting, optimized paths, training) deliver 10-20% gains.

Storage cost per unit combines facility costs (rent, utilities, maintenance), labor costs (putaway, cycle counting, replenishment), and equipment costs (forklifts, automation) divided by units stored. This metric enables benchmarking against industry standards and comparison of different storage strategies. Cost per pallet position or cost per cubic foot helps evaluate investments in automation or facility expansion.

By implementing effective storage processes supported by appropriate technologies, warehouses maximize space utilization while maintaining accessibility and accuracy, creating efficient operations that support rapid order fulfillment at minimal cost.

🔧Related Technologies (6)

MINI-LOAD Automated Small-Parts Storage System

byDAMBACH

Piolax Canton Georgia Automotive Parts Distribution Center

byDaifuku

Meyer Corporation USA Cookware Distribution Center

byDaifuku

Intralogistics Innovation Center: Integrated Solutions Showcase

byDaifuku

Mid-Load Automated Storage & Retrieval System (AS/RS)

by Conveyco

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb