Truck Loading

Truck loading is the warehouse process of placing shipments into trailers efficiently to maximize space utilization, ensure load stability, and enable efficient delivery operations.

🧠 Truck Loading Operations Overview

Interactive overview of loading technologies and strategies - click to explore each category

Loading Systems

Dock Equipment

Load Optimization

Safety & Efficiency

Process Flow and Business Characteristics

Load planning determines optimal placement of shipments in trailers considering multiple factors. Delivery sequence places last-delivery items in first (rear of trailer) and first-delivery items in last (front of trailer) for multi-stop routes, enabling efficient unloading without rearranging loads. Weight distribution places heavier items forward and low (near trailer axles) with lighter items back and high, maintaining proper weight on drive axles and preventing trailer sway. Product compatibility separates incompatible products (food and chemicals, fragile and heavy items) to prevent contamination or damage. Cube optimization arranges items to maximize trailer volume utilization, typically targeting 80-90% for mixed loads.

Staging and sequencing organize shipments in dock areas for efficient loading. Load-sequence staging arranges items in reverse loading order, enabling workers to load items sequentially without searching. Pallet staging groups pallets by destination or route, floor-load staging organizes loose boxes or cases, and mixed-load staging combines palletized and floor-loaded items. Staging capacity must accommodate peak volumes without creating congestion, typically requiring 1.5-2x trailer capacity to buffer multiple loads simultaneously.

Physical loading methods vary based on shipment characteristics and equipment. Palletized loading uses forklifts to place pallets in trailers, achieving 15-25 pallets per hour (30-45 minutes for 28-pallet trailer) with minimal physical labor. Floor loading requires workers to manually place boxes or cases, achieving 150-250 boxes per hour (2-4 hours for 800-1,200 box trailer) with significant physical effort. Mixed loading combines palletized and floor-loaded items, with pallets typically loaded first to create stable base layers. Slip-sheet loading uses specialized attachments to handle unitized loads without pallets, saving weight and space.

Load securing prevents shipment shifting during transit that causes damage or creates safety hazards. Load bars (adjustable bars wedged between trailer walls) create barriers preventing forward movement during braking. Straps and nets secure tall or unstable loads, dunnage (airbags, wood bracing) fills gaps preventing lateral movement, and anti-slip mats increase friction between pallets and trailer floors. Proper securing reduces damage rates from 3-5% (unsecured) to under 1% (properly secured) while preventing load shifts that affect vehicle handling.

Weight distribution and compliance ensure safe vehicle operation and regulatory compliance. Axle weight limits (typically 12,000 pounds front, 34,000 pounds rear tandem for US trucks) must not be exceeded to avoid fines and safety issues. Gross vehicle weight (80,000 pounds maximum in US) limits total load weight. Load planning software calculates weight distribution considering item weights and positions, flagging violations before loading. Onboard scales verify actual weights, enabling adjustments before departure. Bridge formulas govern weight distribution across axles based on axle spacing.

Automation Technologies

Load planning software optimizes trailer loading through algorithms considering delivery sequence, weight distribution, cube utilization, and product compatibility. 3D visualization shows proposed load configurations before loading begins, enabling validation and adjustment. Multi-stop optimization sequences items for efficient unloading at each delivery point. Constraint management enforces rules for weight limits, product separation, and stacking restrictions. Integration with WMS enables automatic load planning based on order data, improving cube utilization by 10-20% compared to manual planning.

Warehouse management systems (WMS) coordinate loading operations with upstream processes, managing staging, directing loading sequences, and tracking load progress. Load assignment determines which orders load on which trucks, staging management directs shipments to appropriate dock doors, and loading task management guides workers through optimal loading sequences. Real-time tracking monitors load progress and alerts supervisors to delays. Integration with TMS enables coordination between warehouse and transportation operations.

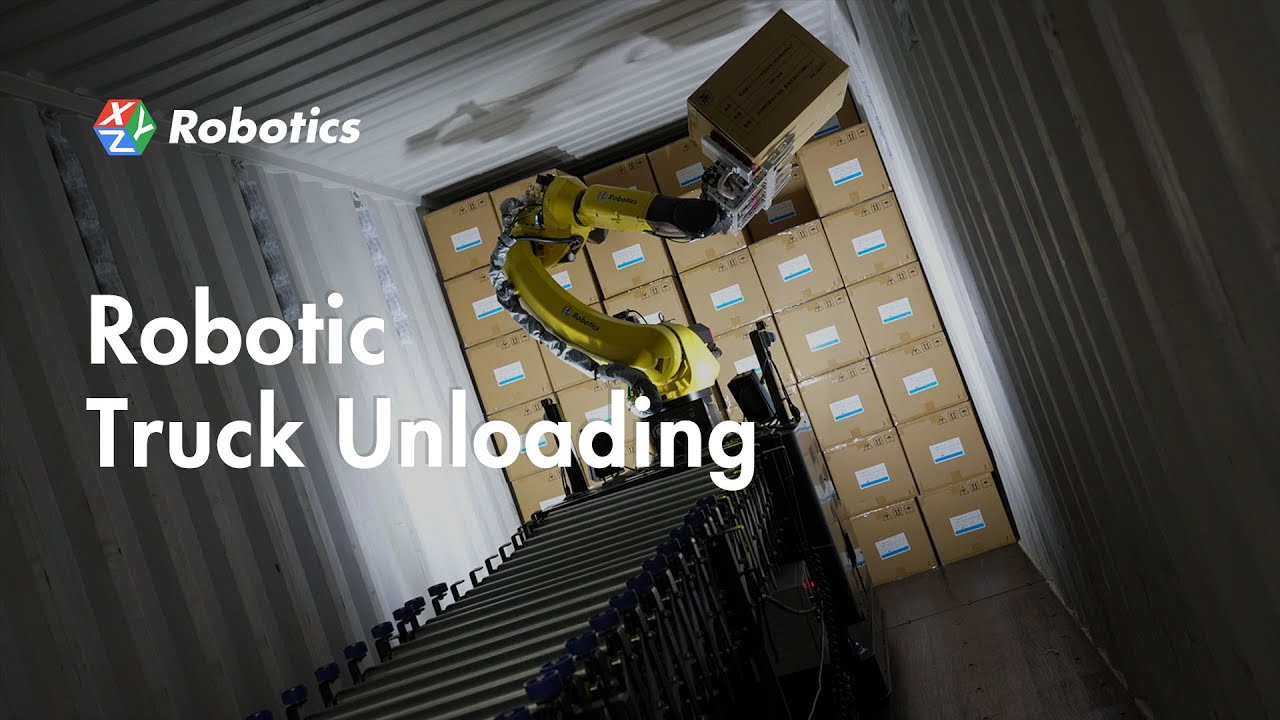

Automated loading systems reduce manual labor and improve loading speed. Extendable conveyors reach into trailers, enabling workers to place boxes on conveyors rather than carrying them into trailers, improving productivity by 30-50% and reducing physical strain. Robotic loading systems use vision and grippers to place boxes in trailers following programmed patterns, handling 600-1,000 boxes per hour. Automated guided vehicles (AGVs) transport pallets from staging areas to trailers, eliminating forklift travel and improving safety. Slip-sheet handlers automate loading of slip-sheet loads, achieving 20-30 loads per hour.

Vision systems and AI enhance loading operations through automated verification and optimization. Load verification uses cameras to photograph trailer contents during and after loading, documenting load configuration and condition. Damage detection identifies crushed boxes or improper stacking requiring correction before departure. Load optimization AI learns from historical loads to improve planning algorithms, identifying patterns that maximize cube utilization while minimizing damage. Real-time guidance projects loading patterns onto trailer floors or displays them on screens, guiding workers to optimal placement.

Dock management systems coordinate loading operations across multiple docks, managing door assignments, tracking load progress, and scheduling carrier departures. Door assignment optimizes dock utilization by matching loads to appropriate doors based on trailer type, load size, and departure time. Load tracking monitors progress of each load, alerting supervisors to delays or problems. Carrier coordination notifies carriers when loads are complete and trailers are ready for departure. Analytics identify bottlenecks and optimization opportunities.

Automated weighing systems verify load weights and weight distribution to ensure compliance and safety. Axle scales measure individual axle weights, identifying distribution problems before departure. Onboard scales in trailers provide real-time weight feedback during loading, enabling adjustments to achieve optimal distribution. In-motion scales weigh loaded trailers as they exit facilities, verifying compliance without stopping. Integration with load planning enables comparison of actual vs. planned weights, improving planning accuracy over time.

Mobile technology provides real-time information and guidance to loading workers. Tablets or smartphones display load plans with 3D visualizations, barcode scanning verifies items are loaded to correct trailers, and photo documentation captures load condition for quality review and dispute resolution. Voice-directed loading provides hands-free guidance through headsets, improving productivity by 10-20%. Wearable devices (smart glasses, wrist scanners) enable workers to access information and scan items without handling devices.

Key Performance Indicators

Cube utilization measures the percentage of trailer volume occupied by shipments, with targets typically 80-90% for mixed loads and 90-95% for uniform products. Low utilization (<70%) indicates poor load planning or insufficient volume, increasing transportation costs per unit shipped. Load planning optimization improves utilization by 10-20% through better arrangement, while shipment consolidation combines orders to fill trailers. Utilization by route and customer identifies opportunities for improvement.

Loading productivity measures pallets or boxes loaded per labor hour, with palletized loading typically achieving 15-25 pallets per hour, floor loading 150-250 boxes per hour, and automated loading 600-1,000+ boxes per hour. Staging quality (items organized in loading sequence) improves productivity by 20-30%, load planning (clear instructions) improves productivity by 10-20%, and equipment availability (forklifts, conveyors) prevents delays. Productivity by worker and shift identifies training needs and best practices.

Loading accuracy measures the percentage of loads with correct items in correct trailers, with targets of 99%+ for operations with barcode verification. Loading errors (wrong items, wrong trailers, missing items) cause delivery failures, customer complaints, and additional transportation costs. Barcode scanning improves accuracy from 95-98% (visual verification) to 99%+ while providing documentation. Root cause analysis identifies whether errors occur during staging or loading, enabling targeted improvements.

Damage rate measures the percentage of shipments arriving damaged, with targets typically under 0.5-1.0%. Loading-related damage from improper stacking, inadequate securing, or poor weight distribution represents 30-50% of total damage. Load securing (bars, straps, dunnage) reduces damage by 60-80%, proper stacking (heavy items on bottom, fragile items protected) prevents crushing, and weight distribution prevents shifting during transit. Damage by route and driver identifies specific problems requiring attention.

Dock door utilization measures the percentage of time docks are actively loading trailers versus idle, with targets typically 70-85% during operating hours. Low utilization indicates insufficient volume, poor scheduling, or operational constraints, while excessive utilization (>90%) suggests insufficient capacity for peak periods. Dock scheduling balances utilization against flexibility, carrier compliance (arriving within scheduled windows) affects utilization, and loading productivity determines how long trailers occupy docks.

On-time departure measures the percentage of trucks leaving within scheduled windows, with targets typically 95%+ for most operations. Late departures cause delivery delays, driver complaints, and potential detention charges. Root cause analysis identifies whether delays occur during picking, packing, staging, or loading, enabling targeted improvements. Real-time monitoring alerts supervisors to loads at risk of missing departure windows, enabling intervention.

Weight compliance measures the percentage of loads meeting axle weight and gross vehicle weight limits, with targets of 100% (violations create legal and safety issues). Overweight violations result in fines ($100-10,000+ depending on severity), delivery delays (requiring load adjustment), and safety risks (brake failures, tire blowouts, loss of control). Load planning prevents violations through accurate weight calculation, while onboard scales verify compliance before departure.

By implementing effective truck loading processes supported by appropriate automation technologies, warehouses maximize transportation efficiency while ensuring safe, damage-free delivery of products to customers at minimal cost.