Transport

Transport is the warehouse process of moving materials, products, and equipment between locations within the facility to support receiving, storage, picking, and shipping operations.

🧠 Transport Operations Overview

Interactive overview of transport technologies and strategies - click to explore each category

Conveyor Systems

AGV & AMR

Transport Strategies

Control & Integration

Process Flow and Business Characteristics

Horizontal transport methods move products across warehouse floors using various equipment and approaches. Manual transport with carts, pallet jacks, or hand trucks provides flexibility for low-volume operations, achieving 50-150 feet per minute with frequent stops for loading and unloading. Forklift transport handles palletized loads at 200-400 feet per minute, with counterbalance forklifts for general use, reach trucks for narrow aisles, and order pickers for elevated picking. Conveyor transport provides continuous flow at 100-300 feet per minute, ideal for high-volume operations with predictable routes.

Vertical transport moves products between mezzanines, multi-level storage, or different facility floors. Forklifts with elevated capabilities handle pallets up to 30-40 feet, vertical reciprocating conveyors (VRCs) lift pallets or carts between levels at rates of 30-60 cycles per hour, and spiral conveyors provide continuous vertical transport in compact footprints. Elevators handle heavy loads or large volumes, while vertical lift modules (VLMs) integrate storage and vertical transport in automated systems. Mezzanines double usable space by adding intermediate levels, with transport systems connecting levels efficiently.

Putaway transport moves received products from dock areas to storage locations, representing 15-25% of warehouse labor in typical operations. Direct putaway moves products immediately from receiving to final storage locations, minimizing handling and storage time. Staged putaway holds products in receiving areas until storage locations are assigned and resources are available, providing flexibility but requiring additional handling. Cross-docking bypasses storage entirely, moving products directly from receiving to shipping for immediate distribution, eliminating storage and retrieval labor.

Replenishment transport moves inventory from reserve storage to forward pick locations as items are depleted, maintaining pick location stock levels. Demand-based replenishment triggers when pick locations reach minimum thresholds, time-based replenishment occurs on schedules (nightly, shift changes), and opportunity-based replenishment occurs when equipment and labor are available between other tasks. Efficient replenishment minimizes pick location stockouts (preventing order delays) while avoiding overfilling (wasting prime pick space).

Pick transport moves picked items from storage areas to packing or sorting areas, with methods varying by picking strategy. Discrete picking has workers transport complete orders directly to packing, batch picking requires transport to sorting areas for order consolidation, and zone picking involves transport between zones as orders accumulate items. Conveyor systems automate transport for high-volume operations, while AGVs or AMRs provide flexible automated transport that adapts to changing requirements.

Automation Technologies

Conveyor systems provide continuous automated transport for high-volume operations, eliminating manual material handling labor. Belt conveyors handle most products at 100-300 feet per minute, roller conveyors provide accumulation and buffering, chain conveyors handle heavy pallets, and overhead conveyors transport items above work areas to preserve floor space. Sortation conveyors with diverters route items to destinations, while merge conveyors combine flows from multiple sources. Modular designs enable reconfiguration as requirements change.

Automated guided vehicles (AGVs) follow fixed paths using wires, magnets, or reflective tape to transport pallets, carts, or totes without human operators. Unit load AGVs transport pallets between receiving, storage, and shipping at rates of 200-300 feet per minute, tugger AGVs pull trains of carts through facilities, and forklift AGVs handle automated putaway and retrieval. Fleet management systems coordinate multiple vehicles, optimize routing, and manage charging. Typical implementations achieve 20-40% labor reduction with 99%+ reliability.

Autonomous mobile robots (AMRs) navigate dynamically using sensors and mapping rather than following fixed paths, providing greater flexibility than AGVs. Goods-to-person AMRs transport shelving units or bins to stationary workers, eliminating 60-70% of pick travel time. Collaborative AMRs follow workers during picking, carrying totes or cartons and eliminating manual cart pushing. Pallet-moving AMRs transport pallets between locations, adapting routes based on real-time conditions. Scalability allows adding robots as volume grows without infrastructure changes.

Vertical transport automation moves products between levels efficiently. Vertical reciprocating conveyors (VRCs) lift pallets or carts automatically at rates of 30-60 cycles per hour, spiral conveyors provide continuous vertical transport at 50-100 feet per minute, and vertical lift modules (VLMs) integrate automated storage with vertical transport. Automated elevators handle heavy loads with programmable controls, while robotic shuttles in multi-level AS/RS systems provide both horizontal and vertical transport within storage structures.

Warehouse management systems (WMS) optimize transport operations through intelligent task assignment and routing. Task interleaving combines putaway and retrieval tasks to minimize empty travel, improving productivity by 20-30%. Zone-based assignments direct workers to areas minimizing travel distance. Real-time traffic management prevents congestion in aisles and intersections. Labor management modules track productivity and balance workload across workers and equipment. Integration with automation coordinates manual and automated transport for optimal flow.

Warehouse execution systems (WES) coordinate multiple automation technologies (conveyors, sorters, AGVs, AS/RS) into integrated material flows. Real-time optimization adjusts routing and priorities based on current conditions, buffer management prevents bottlenecks by controlling flow rates, and exception handling reroutes items around equipment failures or congestion. Simulation capabilities model different scenarios before implementation, while analytics identify optimization opportunities.

Fleet management systems optimize forklift and mobile equipment operations through operator assignment (matching equipment to tasks), maintenance scheduling (preventing breakdowns), impact monitoring (detecting rough handling), and utilization tracking (identifying underused assets). Telematics provide real-time location and status data, access control prevents unauthorized use, and battery management optimizes charging schedules for electric equipment. Analytics identify training needs and process improvements.

Key Performance Indicators

Transport productivity measures moves per labor hour, varying significantly by method and product type. Manual pallet transport typically achieves 15-25 moves per hour, forklift transport 20-40 moves per hour, AGV transport 30-60 moves per hour (per vehicle), and conveyor transport 1,000-3,000+ items per hour depending on system design. Empty travel percentage (time spent traveling without loads) indicates efficiency, with targets typically under 20-30%. Task interleaving reduces empty travel by combining putaway and retrieval tasks.

Travel distance per task measures efficiency of warehouse layout and task assignment, with targets varying by facility size and product velocity. Slotting optimization placing fast-moving items near packing areas reduces pick travel by 20-40%, zone-based assignments limit worker travel areas, and cross-aisles provide shortcuts reducing travel by 10-20%. Heat mapping visualizes travel patterns, identifying opportunities for layout improvements or slotting adjustments.

Equipment utilization tracks the percentage of time equipment is actively transporting products versus idle, with targets typically 60-75% for forklifts (allowing time for operator breaks and maintenance) and 80-90% for automated systems. Low utilization indicates excess capacity or inefficient task assignment, while excessive utilization (>90%) suggests insufficient capacity for peak periods. Downtime tracking identifies maintenance needs or operational constraints requiring attention.

Transport cost per move combines labor costs (operators, maintenance), equipment costs (purchase, lease, maintenance, energy), and facility costs (aisles, ramps, conveyors) divided by moves completed. Automation ROI calculations compare current manual costs against projected automated costs, typically showing payback periods of 3-5 years for AGVs and 5-7 years for conveyor systems. Energy costs for electric forklifts or automated systems represent 5-15% of total transport costs, making battery management and energy-efficient equipment valuable.

Congestion and bottlenecks measure delays from traffic conflicts or capacity constraints. Aisle congestion occurs when multiple vehicles compete for limited space, intersection delays happen at crossing points, and dock congestion results from insufficient staging space. Traffic management systems coordinate equipment movements to minimize conflicts, one-way aisles eliminate head-on conflicts, and staging areas buffer products between process steps. Simulation modeling identifies congestion points before they impact operations.

Safety metrics track incidents involving transport equipment, with targets of zero injuries and minimal property damage. Forklift accidents (collisions, tip-overs, pedestrian strikes) indicate training needs or facility design problems. Operator certification programs ensure proper training, pedestrian separation (barriers, designated walkways) reduces interaction risks, and speed limits in congested areas prevent accidents. Impact monitoring on forklifts identifies rough handling requiring coaching.

By implementing effective transport processes supported by appropriate automation technologies, warehouses minimize non-value-added material handling time and cost while maintaining efficient product flows that support rapid order fulfillment and high productivity.

🔧Related Technologies (6)

AI-Powered Robotic Truck Loading System

byOthers

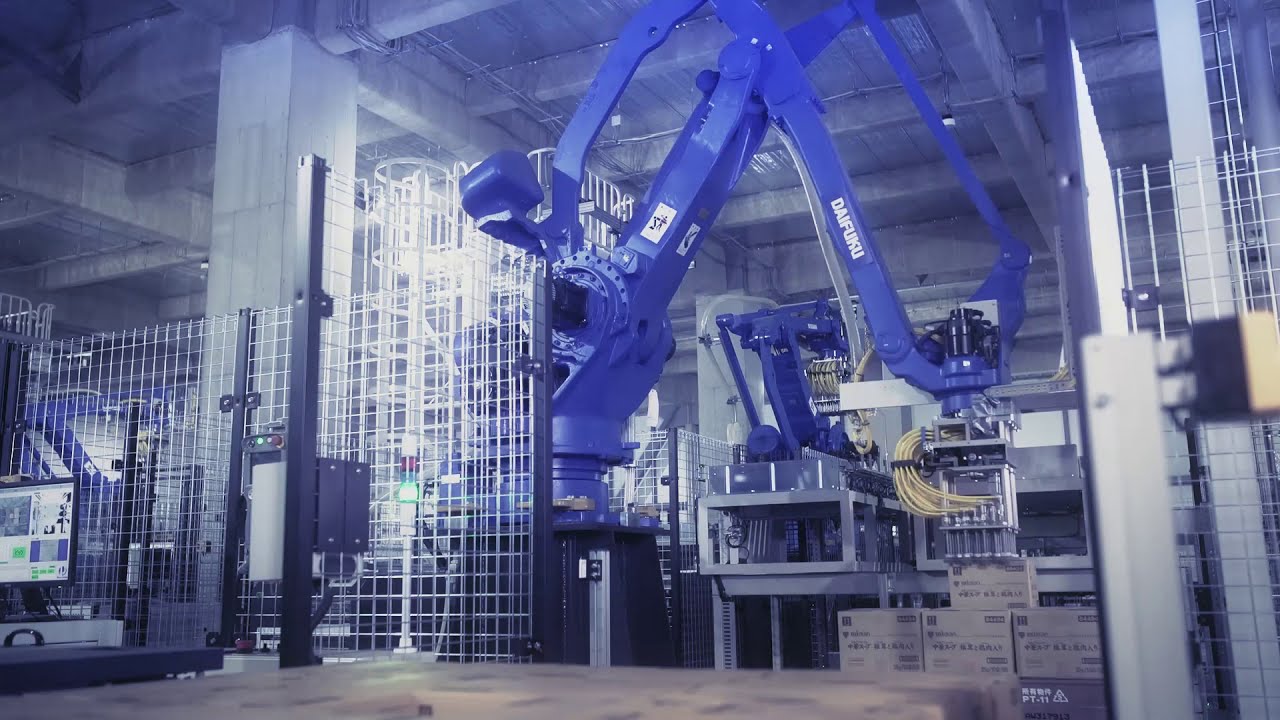

Piolax Canton Georgia Automotive Parts Distribution Center

byDaifuku

Meyer Corporation USA Cookware Distribution Center

byDaifuku

TiltSort-Bot: Autonomous Mobile Robot (AMR) for Sortation

by Conveyco

Industrial Robotic Palletizing System for Bulk Bags

byColumbia/Okura LLC

Skateloader: Automatic One-shot Loading System

byAncra Systems