Picking

Picking is the warehouse process of retrieving products from storage locations to fulfill customer orders, representing the most labor-intensive and cost-critical operation in most facilities.

🧠 Picking Operations Overview

Interactive overview of picking technologies and strategies - click to explore each category

Picking Technologies

Robotic Systems

Picking Strategies

Optimization Tools

Process Flow and Business Characteristics

Order release and wave planning group orders for efficient picking based on order profiles (single-line vs. multi-line), delivery requirements (same-day, next-day, standard), product locations (zone assignments), and resource availability (labor, equipment, packing capacity). Wave planning releases batches of orders at scheduled intervals throughout the day, balancing workload across shifts while meeting shipping cutoff times. Dynamic wave planning adjusts release timing based on real-time conditions, optimizing resource utilization and throughput.

Pick path optimization determines the sequence workers follow through the warehouse to minimize travel distance and time. S-shaped routing has pickers traverse every aisle containing picks, return routing has them enter and exit aisles from the same end, while midpoint routing allows entry from either end based on proximity. Optimal routing algorithms calculate the shortest path considering all pick locations, reducing travel by 20-40% compared to simple strategies. The choice depends on facility layout, aisle configuration, and order characteristics.

Picking methods vary based on order profiles and operational priorities. Discrete picking (pick-and-pack) has workers pick complete orders one at a time, ideal for low-volume operations or orders requiring special handling. Batch picking groups multiple orders for simultaneous picking, with workers collecting quantities for all orders in one pass then sorting items afterward, improving productivity by 30-50% for multi-line orders. Zone picking assigns workers to specific areas, with orders passing between zones to collect all items, reducing congestion and enabling specialization.

Wave picking combines batch and zone approaches, releasing groups of orders simultaneously with workers picking their zones in parallel. Cluster picking uses carts with multiple totes, allowing workers to pick for several orders simultaneously while maintaining separation, ideal for e-commerce operations with many single-line orders. Pick-to-tote systems have workers place items in totes that flow through the facility, while pick-to-belt operations place items on conveyors for automated sortation.

Verification and accuracy processes ensure correct products and quantities are picked. Barcode scanning confirms product identity at pick time, preventing wrong-item errors. Pick-to-light and put-to-light systems use illuminated displays to guide workers to correct locations and quantities, achieving 99.9%+ accuracy. Weight verification compares picked quantities against expected weights, catching quantity errors. Vision systems photograph picks for quality review and dispute resolution.

Automation Technologies

Warehouse management systems (WMS) orchestrate all picking activities, generating pick tasks, optimizing paths, directing workers, and tracking progress. Modern WMS platforms use labor management modules to measure productivity and balance workload, slotting optimization to position fast-moving items optimally, and wave planning algorithms to maximize throughput. Mobile devices with barcode scanning provide real-time task direction and confirmation, while voice picking systems enable hands-free operation through headset commands and verbal confirmations.

Pick-to-light and put-to-light systems use illuminated displays at storage locations or sorting positions to guide workers, eliminating paper pick lists and reducing errors. Pick-to-light shows workers which locations to pick from and quantities needed, while put-to-light indicates where to place items during sorting or packing. These systems improve productivity by 30-50% while achieving 99.9%+ accuracy through visual confirmation. Alphanumeric displays show quantities, while button confirmation verifies completion before advancing to the next task.

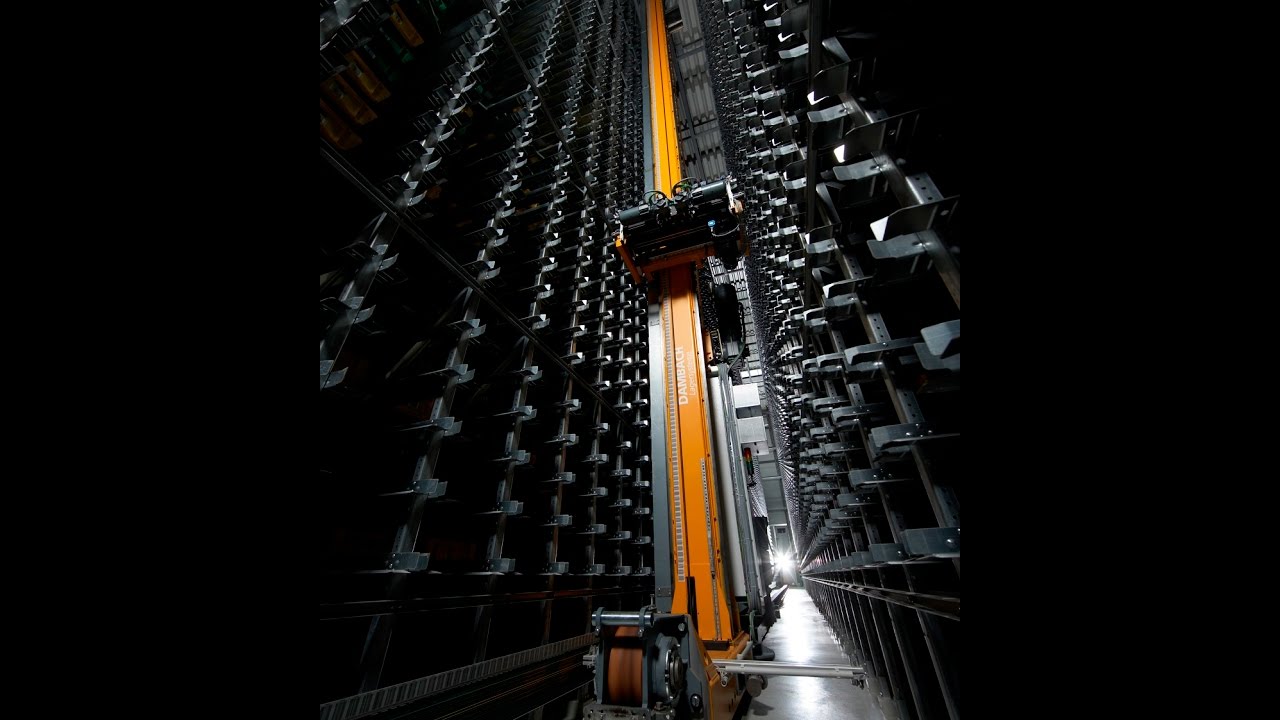

Goods-to-person (G2P) systems bring products to stationary workers rather than having workers travel to products, eliminating 60-70% of labor time spent walking. Automated storage and retrieval systems (AS/RS) deliver totes or trays to pick stations, shuttle systems retrieve bins from high-density storage, and autonomous mobile robots (AMRs) transport shelving units to workers. These systems improve productivity by 2-4x while reducing worker fatigue and improving accuracy through ergonomic workstations with integrated verification.

Robotic picking systems automate product retrieval using vision systems and grippers to handle items. Robotic piece picking uses articulated arms with specialized end-effectors to grasp individual items from bins or shelves, handling 300-600 picks per hour for suitable products. Robotic case picking handles full cases or cartons, achieving 800-1,200 picks per hour. Collaborative robots (cobots) work alongside human pickers, handling repetitive or heavy items while humans manage exceptions. Current technology handles 60-80% of typical SKU mixes, with humans managing difficult items.

Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) transport products or workers through the facility, eliminating manual cart pushing or forklift travel. Cart-pulling AGVs follow fixed paths to deliver picked items to packing areas, while AMRs navigate dynamically around obstacles using sensors and mapping. Collaborative mobile robots follow workers during picking, carrying totes or cartons and eliminating bending and lifting. These systems improve productivity by 20-40% while reducing worker fatigue and injury risk.

Voice picking systems provide hands-free operation through headset-based commands and verbal confirmations, improving productivity by 10-25% while maintaining 99.5%+ accuracy. Workers receive spoken instructions for locations and quantities, verbally confirm picks using check digits, and keep hands free for product handling. Multi-modal systems combine voice with scanning or vision for enhanced verification. Voice-directed work extends beyond picking to putaway, replenishment, and loading operations.

Sortation systems automate the consolidation of picked items to orders, particularly valuable for batch or zone picking operations. Tilt-tray sorters, cross-belt sorters, and sliding-shoe sorters divert items to order lanes or packing stations at rates of 5,000-15,000 items per hour. Put-to-light walls provide manual sortation with visual guidance, handling 200-400 items per hour per worker. Robotic sortation uses mobile robots to transport items to designated positions, providing flexible capacity that scales with volume.

Key Performance Indicators

Pick accuracy measures the percentage of picks completed correctly (right product, right quantity), with targets of 99.5%+ for most operations and 99.9%+ for automated systems. Line accuracy (percentage of order lines picked correctly) and order accuracy (percentage of complete orders picked correctly) provide different perspectives, as a single error affects line accuracy minimally but may make an entire order inaccurate. Root cause analysis identifies whether errors occur from wrong locations, wrong products, or wrong quantities, enabling targeted improvements.

Picks per hour measures productivity, varying dramatically by picking method and product characteristics. Discrete picking typically achieves 40-80 picks per hour, batch picking 80-150 picks per hour, zone picking 100-200 picks per hour, and goods-to-person systems 200-400 picks per hour. Automation can improve productivity by 2-4x, while process improvements (better slotting, optimized paths, training) deliver 20-40% gains. Tracking productivity by method, zone, and worker identifies improvement opportunities.

Pick travel distance measures how far workers walk per pick or per hour, with targets typically under 50 feet per pick for optimized operations. Slotting optimization placing fast-moving items near packing areas, path optimization calculating efficient routes, and zone picking limiting travel areas all reduce distance. Goods-to-person systems eliminate travel entirely, while collaborative robots reduce walking by carrying items alongside workers.

Order cycle time measures elapsed time from order release to pick completion, with targets varying by order profile and service requirements. Same-day orders may require completion within 2-4 hours, while standard orders allow 12-24 hours. Wave planning balances cycle time against efficiency, as larger waves improve productivity but increase cycle time. Real-time monitoring identifies bottlenecks or delays requiring intervention.

Pick labor cost per line combines direct labor (pickers), indirect labor (supervision, training), and equipment costs (forklifts, mobile devices, automation) divided by lines picked. This metric enables benchmarking against industry standards and comparison of different picking methods. Cost per order provides an alternative view for operations with varying lines per order. Automation ROI calculations compare current costs against projected costs with automation, considering capital investment and ongoing operating costs.

By implementing effective picking processes supported by appropriate automation technologies, warehouses maximize productivity while maintaining accuracy, creating efficient fulfillment operations that meet customer expectations at minimal cost.

🔧Related Technologies (6)

Peerless Clothing USA Apparel Distribution Warehouse

byElement Logic

AI-Powered Robotic Truck Loading System

byOthers

Piolax Canton Georgia Automotive Parts Distribution Center

byDaifuku

Intralogistics Innovation Center: Integrated Solutions Showcase

byDaifuku

Robotic Palletizing with Multi-Pick End Effector

byColumbia/Okura LLC

Industrial Robotic Palletizing System for Bulk Bags

byColumbia/Okura LLC