Packing

Packing is the warehouse process of preparing picked items for shipment by placing them in appropriate containers with protective materials, labels, and documentation to ensure safe delivery.

🧠 Packing Operations Overview

Interactive overview of packing technologies and strategies - click to explore each category

Packing Technologies

Packing Strategies

Sustainable Practices

Quality & Experience

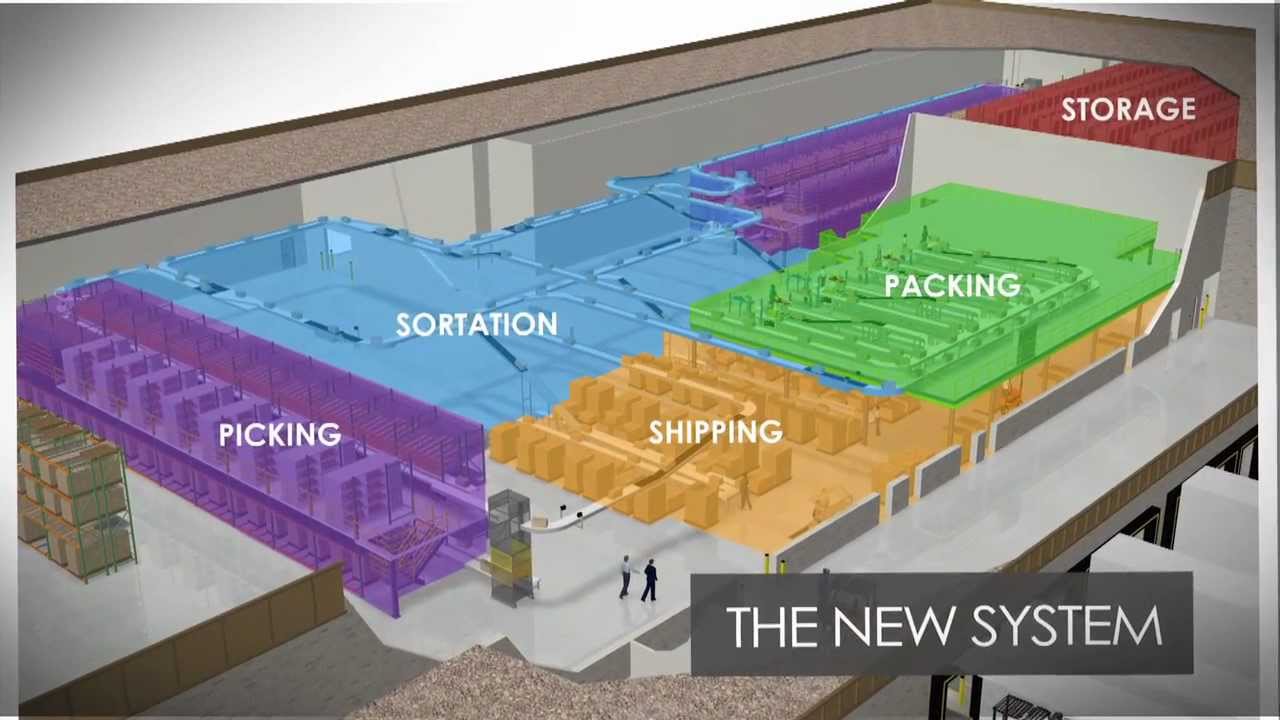

Process Flow and Business Characteristics

Carton selection matches container size to order contents, balancing product protection (adequate space for cushioning), shipping cost (minimizing dimensional weight), and packing efficiency (standard sizes that pack quickly). Cartonization algorithms in warehouse management systems recommend optimal box sizes based on item dimensions and fragility, reducing shipping costs by 10-20% compared to arbitrary selection. Standard carton programs limit box sizes to 6-12 options that nest efficiently and qualify for carrier discounts, while custom sizing systems create right-sized boxes on demand, eliminating void fill and reducing dimensional weight charges.

Item placement and cushioning protects products during transit while presenting them attractively to customers. Fragile items require protective materials (bubble wrap, air pillows, foam) to prevent damage from impacts and vibration. Heavy items go on the bottom with lighter items on top to prevent crushing. Void fill (paper, air pillows, biodegradable peanuts) prevents items from shifting during transit. E-commerce operations emphasize unboxing experience with branded materials, tissue paper, and thoughtful presentation that creates positive customer impressions and social media moments.

Quality verification ensures orders are complete and correct before sealing packages. Visual inspection confirms all items from the pick list are present and undamaged. Barcode scanning verifies product identity and quantity, catching picking errors before shipment. Weight verification compares package weight against expected weight based on contents, flagging discrepancies for review. Vision systems photograph package contents for quality review and dispute resolution, providing evidence if customers claim missing or wrong items.

Documentation and labeling provide information for carriers and customers. Packing slips list order contents for customer reference and return processing. Shipping labels contain carrier routing information, tracking numbers, and delivery addresses. Compliance labels (hazmat, lithium battery, fragile) ensure proper handling. Return labels simplify the returns process for customers. Customs documentation (commercial invoices, certificates of origin) enables international shipments. Automated label application systems print and apply labels at rates of 30-60 packages per minute.

Manifesting and carrier integration closes out shipments and schedules pickups. Manifesting transmits shipment details to carriers, generating tracking numbers and enabling customer notifications. Rate shopping compares carrier rates and service levels to select optimal shipping methods. Carrier integration enables real-time tracking updates and delivery confirmation. End-of-day closeout finalizes shipments and generates pickup lists for carrier drivers.

Automation Technologies

Warehouse management systems (WMS) orchestrate packing operations, directing workers to pack stations, providing pick lists and packing instructions, recommending carton sizes, and generating shipping labels. Modern WMS platforms integrate with carrier systems for rate shopping and manifesting, quality control modules for verification workflows, and labor management systems for productivity tracking. Pack station displays show order details, packing instructions, and verification prompts, guiding workers through standardized processes.

Automated cartonization systems calculate optimal box sizes based on item dimensions, weights, and fragility rules, reducing shipping costs by 10-20% through better size selection. These systems consider carrier dimensional weight rules (DIM weight = length × width × height ÷ divisor), item stacking rules (what can go on top of what), and cushioning requirements (minimum void space for protection). Machine learning improves recommendations over time by analyzing actual packing outcomes and damage rates.

On-demand packaging systems create right-sized boxes for each order, eliminating void fill and reducing dimensional weight charges by 20-40%. Box-making machines convert flat cardboard into custom-sized boxes in 5-10 seconds, with systems handling 500-800 boxes per hour. Automated bagging systems create poly mailers sized to contents for soft goods. These systems reduce packaging material costs by 20-30% while improving sustainability through material reduction.

Automated packing systems handle repetitive packing tasks at high speeds. Robotic case packing places items into boxes using vision systems and grippers, handling 600-1,200 items per hour for suitable products. Automated void fill dispensers inject appropriate amounts of air pillows or paper based on box size and contents. Automated tape sealers close and seal boxes at rates of 20-30 per minute. Integrated packing lines combine these technologies into continuous workflows handling 1,000-2,000 orders per hour.

Print-and-apply labeling systems automatically print shipping labels and apply them to packages at rates of 30-60 per minute, eliminating manual label placement and improving accuracy. Vision systems verify label placement and readability before packages proceed to shipping. RFID label encoding embeds tracking information for enhanced visibility. Multi-label applicators handle packages requiring multiple labels (shipping, return, compliance) in a single operation.

Automated weighing and dimensioning systems capture package characteristics for carrier manifesting and cost verification. In-motion scales weigh packages as they move on conveyors, while dimensioning systems use lasers or cameras to measure length, width, and height. Integrated systems combine weighing and dimensioning in a single pass, processing 30-60 packages per minute. Data feeds to WMS for freight audit (verifying carrier charges) and cartonization optimization (improving future box selection).

Vision inspection systems photograph package contents before sealing, providing quality documentation and dispute resolution evidence. AI-powered systems compare images to order details, flagging potential errors for human review. 360-degree imaging captures all sides of packages for damage documentation. Cloud storage retains images for 30-90 days, enabling customer service teams to resolve disputes quickly without physical inspection.

Key Performance Indicators

Packing accuracy measures the percentage of packages shipped with correct contents, with targets of 99.5%+ for most operations and 99.9%+ for systems with automated verification. Order accuracy (complete orders correct) and line accuracy (individual items correct) provide different perspectives. Root cause analysis identifies whether errors occur during picking or packing, enabling targeted improvements. Customer complaints about wrong or missing items provide external validation of accuracy performance.

Packs per hour measures productivity, varying by order complexity and automation level. Manual packing typically achieves 15-30 packs per hour for multi-item orders, semi-automated packing (with automated cartonization and labeling) 30-50 packs per hour, and fully automated packing lines 60-120 packs per hour. Single-item orders pack faster (40-80 per hour manually) than multi-item orders. Tracking productivity by order type, station, and worker identifies improvement opportunities.

Packaging cost per order combines materials (boxes, cushioning, tape, labels), labor (packing time), and equipment (automation, scales, printers) divided by orders packed. Material costs typically represent 40-60% of total packaging costs, making cartonization optimization and right-sizing valuable. Dimensional weight charges from carriers can add 20-40% to shipping costs for poorly sized packages, making packaging decisions critical to overall fulfillment economics.

Damage rate measures the percentage of shipments arriving damaged, with targets typically under 0.5-1.0%. High damage rates indicate inadequate cushioning, inappropriate box sizes, rough carrier handling, or product packaging issues. Damage by product type and carrier identifies specific problems requiring attention. Packaging testing (drop tests, vibration tests, compression tests) validates that packaging provides adequate protection before deployment.

Packaging sustainability metrics track environmental impact through material usage (pounds per order), recycled content percentage, recyclability (percentage of materials customers can recycle), and right-sizing efficiency (package volume vs. product volume). Sustainability goals drive adoption of paper-based cushioning (replacing plastic), right-sized packaging (reducing material waste), and reusable packaging (for B2B shipments). Customer perception of sustainability affects brand reputation and loyalty.

By implementing effective packing processes supported by appropriate automation technologies, warehouses protect products during shipment while minimizing costs and environmental impact, creating positive customer experiences that drive satisfaction and repeat business.