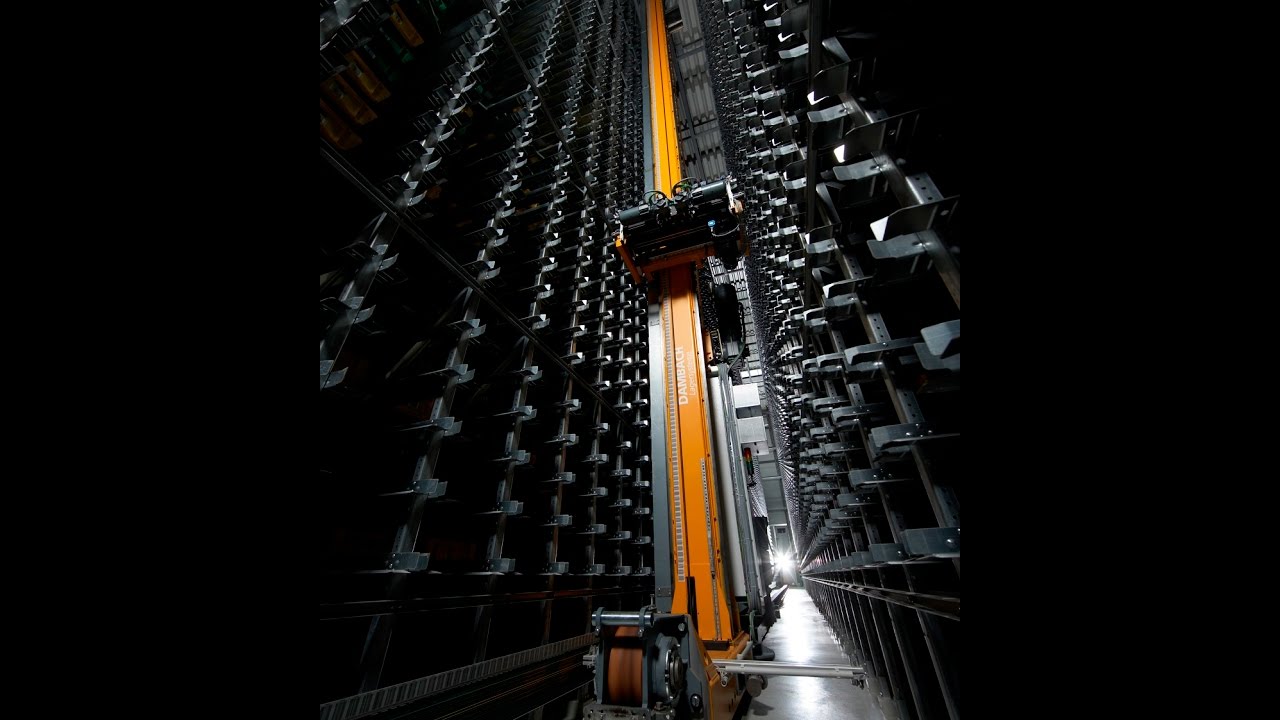

LIEKEN High Bay Cold Store for Baked Goods

⭐Key Features

- •High bay cold store operating at -24°C ambient temperature

- •Capacity for 6,000 pallets of bread and baked goods

- •DAMBACH Storage and Retrieval Machines (SRMs) with custom load-handling devices

- •Designed for operation within an oxygen-reduced atmosphere

- •Achieves 80 storage and 100 retrieval operations per hour per stacker crane

- •Minimum approach dimensions for optimum space utilization

- •Energy-efficient operation

📊Results & Benefits

- ✓4,296 pallet movements realized per day

- ✓Reliable operation in extreme cold (-24°C) and oxygen-reduced conditions

- ✓High storage density and space utilization achieved

- ✓Safe and smooth transport of sensitive foodstuffs

🎯Challenges & Solutions

Transporting sensitive foodstuffs (bread and baked goods) in extreme cold storage conditions (-24°C) and within an oxygen-reduced atmosphere.

Utilized DAMBACH Storage and Retrieval Machines specifically designed and built with proprietary load-handling devices to ensure safe, smooth, and reliable transport under these demanding conditions.

📝Project Overview

Project Overview

This project involved the construction of a specialized high bay cold storage warehouse for LIEKEN, a manufacturer of bread and baked goods. The facility was designed to store a large volume of perishable goods under strictly controlled environmental conditions.

The primary requirement was to create an automated storage system capable of operating reliably in a challenging cold storage environment with an ambient temperature of -24°C. Furthermore, the high bay warehouse features an oxygen-reduced atmosphere, adding another layer of complexity to the equipment's operational requirements. The system needed to ensure the safe and efficient handling of sensitive food products while maximizing storage density.

Technical Solution

DAMBACH Storage and Retrieval Machines (SRMs)

The core of the solution is the DAMBACH Storage and Retrieval Machines (SRMs), which are essentially stacker cranes designed for automated high-bay warehouses. These machines are specifically engineered to operate in the extreme conditions of the facility, including the -24°C temperature and the oxygen-reduced environment.

Meyer Corporation USA Cookware Distribution Center

Vendor: Daifuku

Key Features

The SRMs are built to perform reliably in the harsh environment of a -24°C freezer with an oxygen-reduced atmosphere, a key requirement for preserving certain foodstuffs and ensuring operational safety.

The system demonstrates high throughput capability, with each stacker crane performing 80 storage and 100 retrieval operations per hour. This enables the facility to achieve a total of 4,296 pallet movements per day.

The design of the SRMs and the overall racking layout minimizes wasted space, leading to high storage density. The equipment is also designed for energy efficiency, contributing to lower operational costs in the energy-intensive cold storage environment.

Results & Benefits

The automated system successfully achieves a high volume of 4,296 pallet movements daily, demonstrating its efficiency in supporting LIEKEN's production and distribution logistics.

The DAMBACH SRMs operate with high reliability under the demanding dual conditions of extreme cold and a controlled, oxygen-reduced atmosphere, ensuring consistent warehouse operations.

The use of custom load-handling devices and precision-engineered SRMs ensures that the sensitive baked goods are transported safely and smoothly throughout the storage and retrieval process, maintaining product integrity.

Challenges & Solutions

The primary technical challenge was designing automated equipment that could function effectively and reliably in the extreme cold of -24°C and within the specialized environment of an oxygen-reduced warehouse, all while handling delicate food products. DAMBACH addressed this by providing their own Storage and Retrieval Machines that are engineered for such conditions and by developing custom load-handling devices. This integrated approach guaranteed the safe transport and reliable operation required for this sensitive and demanding application.

System Integrator

DAMBACH Lagersysteme acted as the system provider for the automated storage and retrieval solution. The company, with over 40 years of experience, provided the Storage and Retrieval Machines (SRMs), the custom load-handling devices, and the associated expertise for this cold storage application. The description positions DAMBACH as a reliable partner for system integrators and general contractors, indicating they likely supplied the core SRM technology as part of a larger project.

🔧Related Technologies (6)

Meyer Corporation USA Cookware Distribution Center

byDaifuku

DAMBACH MULTI Series: Curve-Going, Aisle-Changing Stacker Crane

byDAMBACH

Swisslog Vectura Pallet Stacker Crane: Energy-Efficient High-Bay AS/RS

bySwisslog

Piolax Canton Georgia Automotive Parts Distribution Center

byDaifuku

Intralogistics Innovation Center: Integrated Solutions Showcase

byDaifuku

Mid-Load Automated Storage & Retrieval System (AS/RS)

by Conveyco

📚Related Knowledge Articles (2)

Cold Storage Strategy

Cold storage and temperature-controlled warehousing are critical for preserving perishable goods throughout the supply chain. From frozen foods to pharmaceuticals, these specialized facilities maintain precise temperature conditions while optimizing energy efficiency and operational performance.

Food & Beverage Warehousing

Food and beverage warehousing requires specialized automation that addresses unique challenges including temperature control, food safety compliance, and rapid order fulfillment for both retail and foodservice channels.