Our Curated Projects

30 projects

DAMBACH MINI-LOAD Automated Small Parts Storage System

The DAMBACH MINI-LOAD system is an automated storage and retrieval machine for small parts, achieving heights up to 27 meters and high throughput for container and carton storage.

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

A high-bay automated warehouse system using shuttle operation in storage channels to achieve maximum pallet capacity and high throughput, specifically implemented for frozen goods storage.

Roark - Aerospace Tool & Die Automated Storage System

Roark implemented Bastian Solutions' automated storage and retrieval system for aerospace tools and dies, replacing manual pallet storage with organized ASRS for complex sheet metal fabrication.

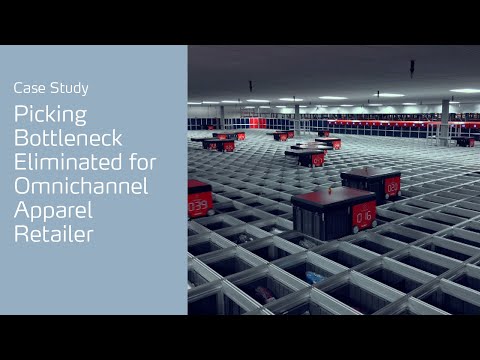

FIEGE Apfelstädt Logistics Center AutoStore System

The logistics service provider FIEGE implemented one of Germany's largest AutoStore systems, integrated with the SuPCIS-L8 WMS, to automate small parts storage and process control at its Apfelstädt center.

Agile Cold Storage Distribution Center

Third-party cold storage facility tripling pallet capacity to 48,000 in 110,000 sq ft using Swisslog ASRS with SynQ software, serving food manufacturers and global export markets.

SHAKE-HAND - Belgian Standard Elements Automated Storage

SHAKE-HAND implemented Kardex Miniload-in-a-Box systems including extended VBM units to replace manual storage, doubling capacity and reducing picking errors for machine builder distribution.

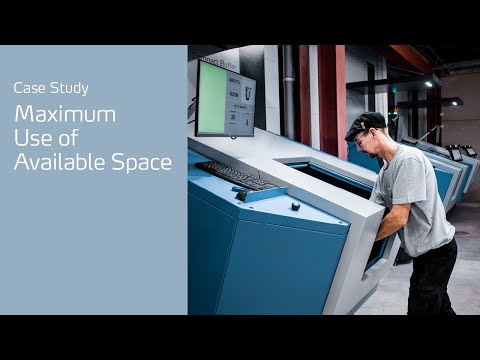

MRG - Retail Distribution Center Automated Goods-to-Person Intralogistics

MRG implemented an automated goods-to-person intralogistics solution by psb at its retail distribution center, featuring 6 rotapick systems and a 6,500-container Multi Access Warehouse to optimize small parts picking efficiency.

LIEKEN High Bay Cold Store for Baked Goods

A high bay cold store for bread and baked goods with a capacity of 6,000 pallets at -24°C, using DAMBACH Storage and Retrieval Machines to achieve 4,296 pallet movements daily.

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

Amway Midwest Regional Service Center, Ada

Amway streamlined its Midwest fulfillment, moving to a new automated facility 50% smaller yet capable of handling over 30,000 cartons daily, achieving faster order fulfillment and reduced costs.

SEW-EURODRIVE Bruchsal Electronics Plant

SEW-EURODRIVE built Europe's most modern electronics plant with GEBHARDT's automated pallet storage and multi-level shuttle system for electronic components.

MPE Plastics Turin Automotive Warehouse

MPE implemented SSI Schaefer's mobile racking and AGV solution to maximize storage capacity and meet automotive industry reliability requirements.

BORT Logistics Center

Viastore implemented an automated logistics center for medical technology manufacturer BORT, featuring bulk storage, picking modules, and comprehensive conveyor systems.

BevChain Australia Distribution Center

Australia's first high-density PowerStore system increasing pallet storage capacity by 60% in the same footprint, handling over 30,000 pallet locations across five levels.