SEW-EURODRIVE Bruchsal Electronics Plant

⭐Key Features

- •Robot-based automatic pallet storage (GEBHARDT Omnipallet)

- •Multi-level shuttle system for small parts storage

- •Five-aisle multi-level shuttle system across six levels

- •Expansion from 30 to 60 meters in total storage cube

- •10,000 pallet storage locations

- •32 level shuttles distributed across different levels

- •Six inbound workstations with package conveyors

- •200-300 large load carriers daily inbound

📊Results & Benefits

- ✓30% more storage area through shuttle system

- ✓Dynamic response times for high-frequency areas

- ✓Europe's most modern electronics plant

- ✓Shortest material flow paths achieved

- ✓Flexible supply of modular manufacturing islands

🎯Challenges & Solutions

Meeting growing future demand for electronic components

Built new plant with advanced automation and logistics concept

Creating highly flexible, dynamic factory operations

Implemented automated storage with shuttle systems and mobile robots

📝Project Overview

Project Overview

SEW-EURODRIVE, a global company supplying components for moving systems with 19 production plants supported by 85 technology centers in 58 countries and 19,000 employees worldwide, faced the challenge of meeting growing future demand for electronic components. The company decided to build a new plant at their Bruchsal location, aiming to create not only state-of-the-art production technology but also an advanced logistics concept.

The vision was to create a highly flexible, dynamic factory that could support modular manufacturing islands flexibly supplied by driverless transport systems. This approach required innovative logistics solutions that could keep pace with modern production requirements while providing the flexibility needed for electronics manufacturing.

SEW-EURODRIVE partnered with GEBHARDT Intralogistics Group from Sinsheim to realize what has become Europe's most modern electronics plant, combining advanced production technology with sophisticated logistics automation.

Technical Solution

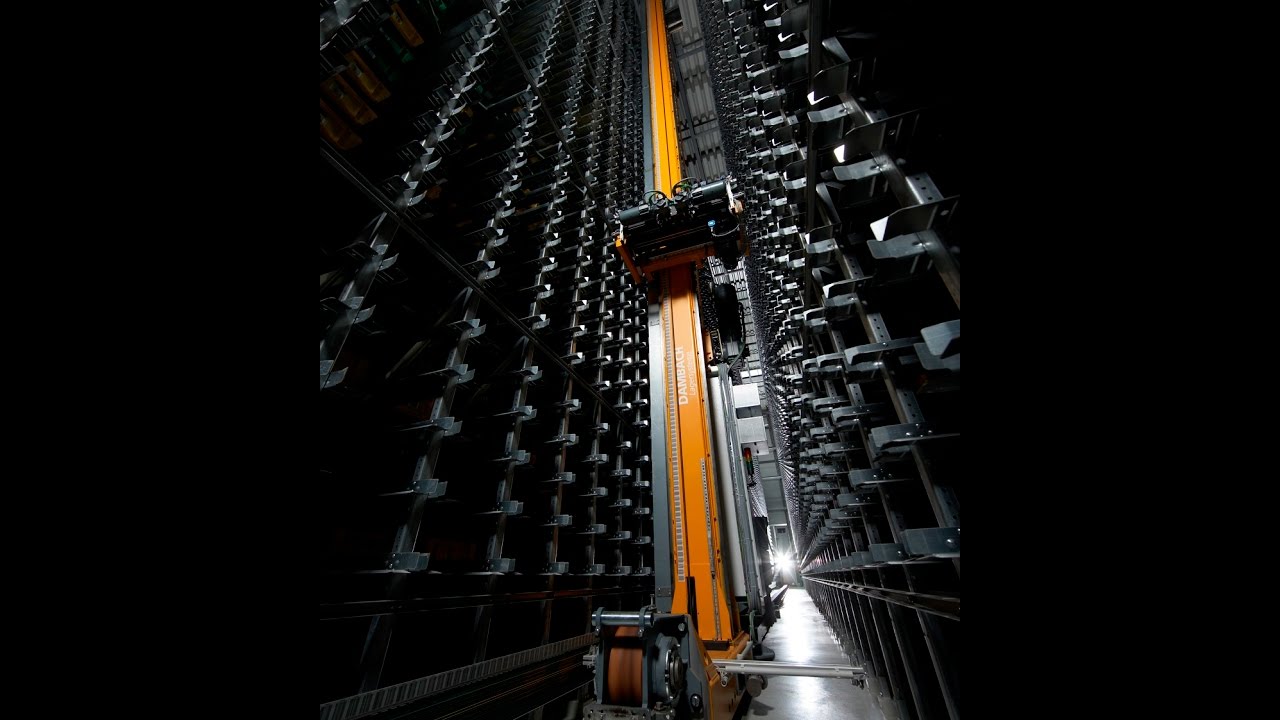

Multi-Level Shuttle System

The facility features a five-aisle multi-level shuttle system spanning six levels, providing automated small parts storage. The system was expanded from 30 to 60 meters in total storage cube, resulting in 30% more storage area compared to conventional systems. This expansion allows the shuttle system to serve high-frequency areas quickly with dynamic response times.

Dark Warehouse: Fully Automated Warehouse Operations

Vendor: Addverb

Key Features

The five-aisle multi-level shuttle system across six levels provides exceptional storage density and access speed, with 32 level shuttles distributed across different levels to handle order loads efficiently based on demand patterns.

The integrated system creates intelligent connections between transport systems and shuttle storage, ensuring containers are available at the right outbound stations at the right time to achieve the shortest material flow paths.

The expansion from 30 to 60 meters in total storage cube represents a significant capacity increase, providing 30% more storage area through the shuttle system design while maintaining efficient access times.

Results & Benefits

The shuttle system delivers 30% more storage area compared to conventional systems, providing the capacity needed to support growing electronic component demand while optimizing facility space utilization.

Dynamic response times are achieved for high-frequency areas, allowing the system to serve frequently accessed products quickly and efficiently, supporting production line requirements.

Europe's most modern electronics plant has been realized, combining advanced production technology with sophisticated logistics automation to create a highly flexible, dynamic factory operation.

Challenges & Solutions

The challenge of meeting growing future demand for electronic components was addressed through the construction of a new plant with advanced automation and logistics concepts, creating scalable capacity for future requirements.

Creating highly flexible, dynamic factory operations required implementing automated storage with shuttle systems and mobile robots that could support modular manufacturing islands with flexible material supply.

System Integrator

GEBHARDT Intralogistics Group served as the system integrator, realizing the robot-based automatic pallet storage (GEBHARDT Omnipallet) in combination with the multi-level shuttle system for small parts storage. The partnership created a win-win situation for both companies, with SEW-EURODRIVE selecting GEBHARDT as a partner for close collaboration. The combination of the one-level pet system with SEW-EURODRIVE's conveyor technology represents a cutting-edge solution for electronics manufacturing logistics.

🖼️Project Gallery

🔧Related Technologies (6)

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

Autopicker: AI-Powered Mobile Picking Robot

byBrightpick

Geek+ PopPick: Next-Generation High-Density Goods-to-Person System

byGeek+

Geek+ RS5-D: Tote-to-Person AMR for Ultra 3D Storage

byGeek+

HaiPick Climb System: Goods-to-Person Warehouse Automation

by Hai Robotics

📚Related Knowledge Articles (6)

Goods-to-Person Systems

Goods-to-Person (G2P) systems revolutionize warehouse operations by bringing inventory directly to stationary picking stations, eliminating worker travel time and maximizing productivity. These automated systems combine storage, retrieval, and presentation technologies to create highly efficient picking environments.

Shuttle Systems

Shuttle systems use autonomous vehicles traveling on rails within racking structures to store and retrieve totes or cartons, providing flexible high-density automated storage with scalable throughput.

Pallet Racking

Pallet racking systems are structural storage solutions that hold palletized goods in horizontal rows with multiple levels, forming the backbone of warehouse operations by maximizing vertical space while maintaining direct access to inventory.

Manufacturing & Industrial Warehousing

Manufacturing warehousing supports production operations with just-in-time material delivery, requiring tight integration with production systems and flexible automation that adapts to changing manufacturing schedules.

Automated Packaging Lines

Comprehensive automated packaging lines that integrate multiple packaging processes into synchronized, high-speed production systems, handling complete packaging workflows from product feeding to final case packing with exceptional throughput and consistency.

Production Logistics Strategy

Production logistics orchestrates the seamless flow of materials, components, and finished goods within manufacturing operations. From just-in-time delivery to line-side replenishment, master the strategies that keep production lines running efficiently while minimizing inventory and maximizing throughput.