Didactic - Normandy France Healthcare Storage Expansion with Pallet Shuttle

⭐Key Features

- •Customized semi-automatic Pallet Shuttle system integrated with pallet racking, supporting 11,000 total pallet capacity

- •Dual FIFO (First-In-First-Out) and LIFO (Last-In-First-Out) inventory management functionality

- •Electromagnet attachment system on shuttle base for safe fork handling and secure pallet movement

- •Flexible unloading options: single units, entire channels, or custom pallet quantities

- •Positioning camera for precise shuttle insertion/centering in high-rise installations

- •Lithium batteries enabling 10-hour continuous operation with easy, safe replacement

📊Results & Benefits

- ✓Expanded storage capacity from 92% utilization to 11,000 pallet capacity, supporting business growth

- ✓Increased warehouse productivity by optimizing operator movements (load moves to operator)

- ✓Enabled efficient handling of high pallet volume per SKU and intensive loading/unloading activity

- ✓Achieved safe, reliable storage and delivery of sterile medical devices

- ✓Rapid system adoption through Mecalux’s training and adherence to assembly timelines

🎯Challenges & Solutions

Critical storage capacity constraints (92% utilization by 2014) hindering business growth

Mecalux delivered a customized Pallet Shuttle + racking solution expanding capacity to 11,000 pallets

High volume of pallets per SKU and intensive loading/unloading activity requiring efficient workflows

Pallet Shuttle system moves loads to operators, reducing unnecessary movements and boosting productivity

Need for flexible inventory management (FIFO/LIFO) for sterile medical device distribution

Dual-mode functionality built into the Pallet Shuttle system to accommodate different inventory strategies

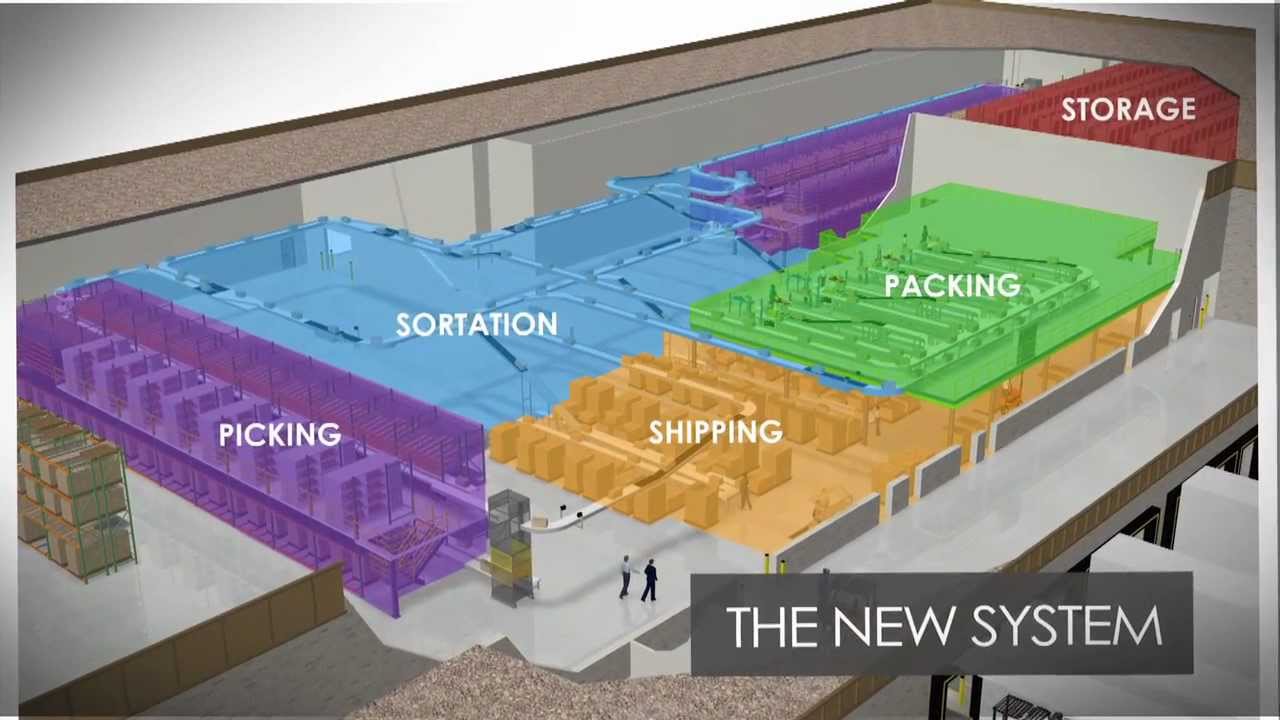

📝Project Overview

Project Overview

Didactic, a leading supplier of sterile medical devices to the French market, faced critical storage capacity constraints at its Normandy facility by 2014. As a burgeoning company, its warehouse had reached 92% capacity, creating a bottleneck that threatened future growth. The core business needs centered on expanding storage capacity while improving operational efficiency to handle the company’s high volume of pallets per SKU and intensive loading/unloading activity.

Given the nature of its business—distributing sterile medical devices—Didactic required a solution that would ensure safe, reliable storage and handling, while supporting flexible inventory management (both FIFO and LIFO) to meet distribution requirements. The project also demanded rapid implementation and operator readiness to minimize disruption to critical healthcare supply chains.

Mecalux was selected to design a customized solution tailored to Didactic’s specific needs, combining pallet racking with semi-automatic Pallet Shuttle technology. The partnership focused on delivering a scalable, efficient system that would address immediate capacity issues and support long-term growth.

Technical Solution

Semi-Automatic Pallet Shuttle System

The centerpiece of the solution is Mecalux’s semi-automatic Pallet Shuttle, integrated with pallet racking to create a high-density storage system. The shuttle operates within rack channels, moving pallets to and from operator positions—eliminating the need for operators to navigate deep racking. The system supports both FIFO and LIFO inventory management, providing flexibility for different product lines and distribution requirements. With a total capacity of 11,000 pallets, the solution directly addressed Didactic’s capacity crunch.

Mecalux Shuttle System: Automated AS/RS for Boxes and Small Parts

Vendor: Mecalux

Key Features

The customized integration of Pallet Shuttle technology with pallet racking delivers a targeted solution for Didactic’s high-volume, high-activity warehouse. The 11,000-pallet capacity directly addresses the 92% utilization crisis, providing room for growth.

Dual FIFO/LIFO functionality ensures flexibility in inventory management, a key requirement for distributing sterile medical devices with varying shelf lives or demand patterns.

The electromagnet attachment system and safety features prioritize product integrity, critical in the healthcare sector where contamination or damage can have serious consequences.

Flexible unloading options (single, channel, custom quantity) adapt to Didactic’s intensive loading/unloading activity, ensuring efficient processing of high pallet volumes per SKU.

The shuttle’s long battery life and easy replacement support continuous operations, while positioning cameras and acoustic/light signals enhance operator efficiency and accuracy—even in high-rise racking.

Results & Benefits

The primary outcome is a significant storage capacity expansion, from 92% utilization to 11,000 pallet capacity, enabling Didactic to support its burgeoning business without compromising operational efficiency.

Warehouse productivity has increased substantially, as the Pallet Shuttle moves loads directly to operators—eliminating unnecessary walking and reducing physical exertion. This optimization is particularly impactful given the company’s high pallet volume per SKU.

The system’s safe handling features and reliable operation ensure the integrity of sterile medical devices throughout storage and handling, supporting Didactic’s commitment to quality healthcare supply.

Mecalux’s adherence to assembly timelines and comprehensive operator training enabled rapid system adoption, minimizing disruption to critical distribution operations.

The flexible FIFO/LIFO functionality and efficient workflows have streamlined inventory management and order fulfillment, ensuring timely delivery of medical devices to the French market.

Challenges & Solutions

Didactic’s most pressing challenge was severe storage capacity constraints (92% utilization by 2014) that threatened growth. Mecalux’s customized solution—combining Pallet Shuttle technology with pallet racking—expanded capacity to 11,000 pallets, directly resolving the bottleneck.

The company’s high volume of pallets per SKU and intensive loading/unloading activity required efficient, operator-friendly workflows. The Pallet Shuttle system addresses this by moving loads to operators, reducing unnecessary movements and significantly boosting productivity.

Didactic needed flexible inventory management to handle sterile medical devices, which may require FIFO (for expiration-sensitive products) or LIFO (for high-turnover items). The Pallet Shuttle’s dual-mode functionality was purpose-built to accommodate both strategies, ensuring alignment with distribution needs.

System Integrator

Mecalux served as the system integrator and solution provider for the project, delivering a fully customized semi-automatic Pallet Shuttle system tailored to Didactic’s unique requirements. The company’s expertise in high-density storage solutions for healthcare applications was critical to designing a system that balances capacity, efficiency, and product safety.

Mecalux’s responsibilities included system design, integration of Pallet Shuttle technology with existing racking, equipment supply, assembly, and operator training. The company’s commitment to adhering to assembly timelines ensured minimal disruption to Didactic’s critical medical device distribution operations.

The successful implementation reflects Mecalux’s ability to deliver industry-specific solutions that address both immediate operational challenges and long-term growth objectives. By combining technical innovation (electromagnet attachment, positioning cameras) with practical usability (easy battery replacement, operator aids), Mecalux enabled Didactic to take a significant step forward in storage, handling, and delivery of healthcare products.

🖼️Project Gallery

🔧Related Technologies (6)

3D Automated Pallet Shuttle: Multi-Directional High-Density AS/RS

byMecalux

Automated Compact Warehouse System with Stacker Crane & Pallet Shuttle

byJungheinrich

Mecalux Shuttle System: Automated AS/RS for Boxes and Small Parts

byMecalux

PowerStore Pallet Shuttle: High-Density Storage for High Throughput

bySwisslog

GEBHARDT StoreBiter HDS: Hive and Drone Pallet Shuttle System

byGEBHARDT Intralogistics Group

Four-Way Pallet Shuttle System: Omni-Directional High-Density AS/RS

byBlueSword

📚Related Knowledge Articles (2)

Shuttle Systems

Shuttle systems use autonomous vehicles traveling on rails within racking structures to store and retrieve totes or cartons, providing flexible high-density automated storage with scalable throughput.

Pallet Racking

Pallet racking systems are structural storage solutions that hold palletized goods in horizontal rows with multiple levels, forming the backbone of warehouse operations by maximizing vertical space while maintaining direct access to inventory.