Pallet Conveyors

Pallet conveyors transport palletized loads through warehouses and manufacturing facilities using powered rollers, chains, or belts, enabling automated material flow between storage, production, and shipping areas.

Pallet Conveyors Overview

Conveyor Types

- •Chain ConveyorsHeavy-duty transport

- •Roller ConveyorsSmooth movement

- •Belt ConveyorsContinuous surface

- •Slat ConveyorsModular design

Key Benefits

- •High Capacity2,000-4,000 lbs

- •Automated FlowContinuous movement

- •Labor Reduction60-80% savings

- •Reliable Operation99%+ uptime

Components

- •Drive SystemsMotors & gearboxes

- •Control SystemsPLC & sensors

- •Safety SystemsGuards & e-stops

- •Support StructureFrame & foundations

Applications

- •WarehousingStorage & distribution

- •ManufacturingProduction lines

- •Food & BeverageProcessing plants

- •AutomotiveParts handling

Features

- •Accumulation ZonesBuffer capacity

- •Transfer SystemsMulti-directional

- •Lift & LowerLevel changes

- •Sorting CapabilityDestination routing

Future Trends

- •Smart ControlsAI optimization

- •IoT IntegrationConnected systems

- •Energy EfficiencyGreen technology

- •Modular DesignFlexible systems

How Pallet Conveyors Work

Roller conveyors use powered rollers spaced along the conveyor frame that rotate to move pallets forward. The rollers are typically 1.9-3.5 inches in diameter, spaced 3-6 inches apart, and driven by motors through chains, belts, or individual motor-driven rollers (MDR). Chain-driven roller conveyors use a single motor with chain drives connecting multiple rollers, providing economical power transmission for straight sections. Motor-driven roller (MDR) conveyors use individual motors integrated into select rollers, enabling zone control where sections can be independently started, stopped, or reversed based on pallet presence and system logic.

Chain conveyors use heavy-duty chains running in tracks on either side of the conveyor that engage with pallet bottom boards, pulling pallets along the conveyor path. This design handles heavier loads (up to 10,000+ pounds) and damaged pallets better than roller conveyors, as the chains provide positive engagement regardless of pallet bottom condition. Dual-strand chain conveyors use two parallel chains for standard pallets, while triple-strand systems support wider loads or provide additional stability. The chains typically run at 30-90 feet per minute, with speed selected based on load weight and system requirements.

Belt conveyors use continuous belts (typically rubber or PVC) running over drive and idler pulleys to transport pallets. The belt surface provides friction to move pallets without requiring engagement with pallet bottom boards, making belt conveyors suitable for pallets with damaged or non-standard bottoms. Slider bed belts run over a smooth surface for lighter loads, while roller bed belts use rollers beneath the belt to reduce friction for heavier loads or longer conveyors. Belt conveyors handle inclines and declines better than roller or chain systems, supporting elevation changes up to 15-20 degrees.

Control systems manage pallet flow through the conveyor network, using sensors (typically photoelectric or proximity sensors) to detect pallet presence and position. Zone control logic starts and stops conveyor sections based on pallet locations, preventing collisions and enabling accumulation where pallets queue without contact. Programmable logic controllers (PLCs) coordinate multiple conveyor sections, managing transfers, diversions, and routing based on operational requirements. Advanced systems integrate with warehouse management systems (WMS) to automatically route pallets to destinations based on product type, order requirements, or storage assignments.

Key Benefits

The primary advantage of pallet conveyors is labor cost reduction by automating material movement that would otherwise require forklift operators. A single conveyor system can replace multiple forklift moves, reducing labor costs while improving consistency and throughput. Operations typically achieve payback periods of 2-4 years through labor savings alone, with additional benefits from improved safety, increased throughput, and better space utilization. The 24/7 operational capability enables continuous material flow without breaks or shift changes, maximizing facility utilization.

Improved safety results from reducing forklift traffic in work areas, eliminating the leading cause of warehouse accidents. Pallet conveyors create predictable material flow along fixed paths, separating product movement from pedestrian and vehicle traffic. The automated operation eliminates risks associated with forklift operation including collisions, tip-overs, and load handling accidents. Facilities typically experience 50-70% reductions in material handling accidents after implementing conveyor systems, lowering workers' compensation costs and improving workplace safety culture.

Increased throughput comes from the continuous, automated material flow that operates at consistent speeds without variation from operator skill, fatigue, or distraction. Pallet conveyors can maintain steady flow rates of 30-100+ pallets per hour depending on system design, often exceeding the throughput achievable with forklift operations. The accumulation capability in zone-controlled systems provides buffering between operations with different cycle times, preventing bottlenecks and maximizing overall system efficiency. Integration with automated storage systems enables fully automated material flow from receiving to storage to shipping without manual intervention.

Space efficiency improves as conveyors follow optimized paths through facilities, often using overhead space or narrow corridors unsuitable for forklift operation. The fixed paths eliminate the need for wide aisles and turning areas required for forklifts, freeing floor space for productive operations. Vertical conveyors or incline/decline sections enable multi-level material flow, maximizing use of building volume. The organized material flow also improves facility layout and workflow by creating clear, predictable product movement patterns.

Common Applications

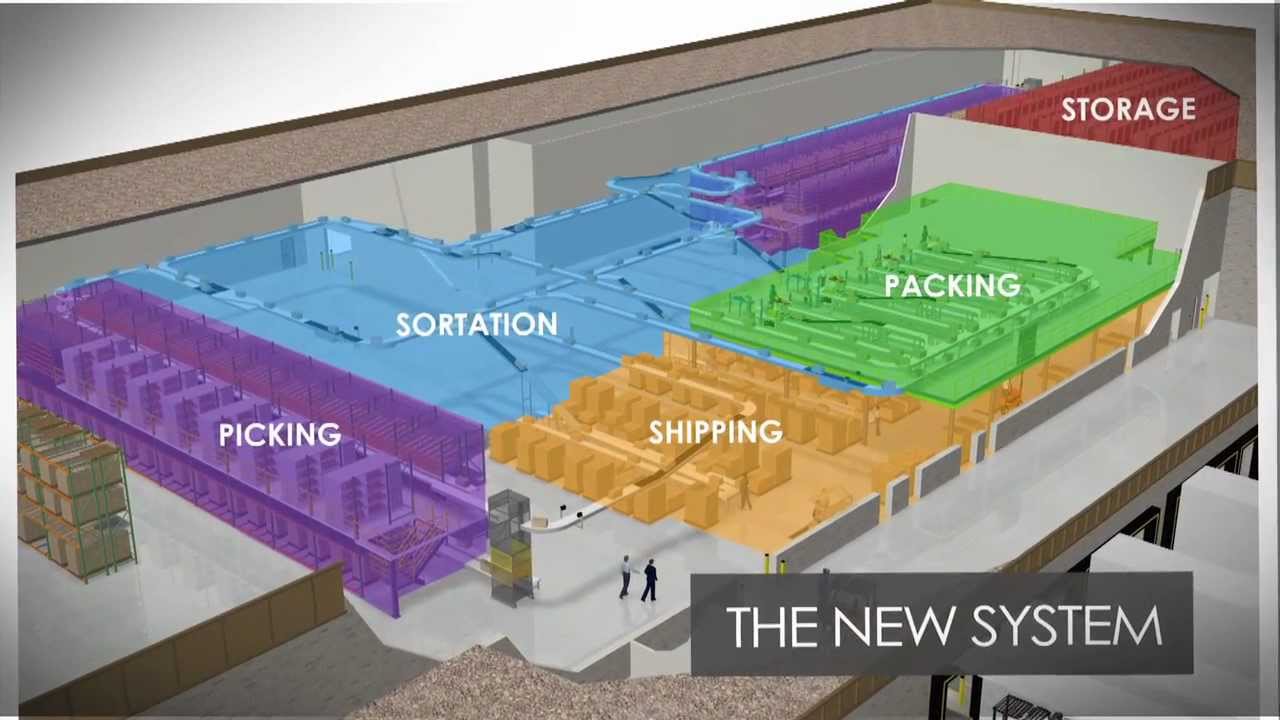

Distribution centers use pallet conveyors to connect receiving docks, storage areas, and shipping docks, automating the flow of pallets through the facility. Receiving operations use conveyors to transport pallets from dock doors to putaway stations or automated storage systems, eliminating forklift travel and improving throughput. Order fulfillment operations use conveyors to deliver pallets from storage to picking areas, then transport completed orders to shipping docks. The automated flow reduces labor costs while improving order accuracy and cycle times.

Manufacturing facilities leverage pallet conveyors for production line feeding, transporting raw materials and components from storage to production areas on demand. The just-in-time delivery reduces work-in-process inventory while ensuring production lines have needed materials without manual coordination. Finished goods handling uses conveyors to transport completed products from production to quality control, packaging, or shipping areas, maintaining smooth flow without requiring production workers to manage material movement.

Cross-docking operations rely heavily on pallet conveyors to rapidly move products from receiving to shipping without intermediate storage. Pallets flow directly from inbound dock doors through the facility to outbound doors based on destination, with sortation systems and automated routing directing pallets to correct locations. The high throughput and minimal handling support the rapid turnaround required in cross-docking operations, often processing 1,000+ pallets per day through a single facility.

Cold storage facilities use pallet conveyors to minimize the time personnel spend in temperature-controlled environments while maintaining efficient material flow. Automated pallet flow through freezers and coolers reduces the need for forklift operators to work in harsh conditions, improving safety and productivity. The sealed conveyor designs minimize air infiltration at dock doors and between temperature zones, reducing energy costs. Insulated conveyor sections maintain temperature control for products moving through ambient areas.

Implementation Considerations

Successful pallet conveyor implementation requires careful load analysis to ensure the system can handle actual pallet weights, dimensions, and bottom conditions. Maximum pallet weight (typically 2,000-4,500 pounds for standard systems) must accommodate the heaviest loads, with adequate safety factors for dynamic loads during acceleration and deceleration. Pallet dimensions must be consistent or the system must accommodate the range of sizes used. Pallet bottom condition is critical for roller conveyors, which require pallets with adequate bottom boards in good condition, while chain conveyors tolerate damaged pallets better.

Layout planning should optimize material flow while accommodating facility constraints and operational requirements. Conveyor paths should minimize travel distance while avoiding obstacles and providing access for maintenance. Curve radii must accommodate pallet dimensions and overhang, typically requiring minimum radii of 4-8 feet for 90-degree turns. Elevation changes using incline/decline sections or vertical conveyors must be planned carefully, with maximum slopes of 10-15 degrees for roller conveyors and up to 20 degrees for belt conveyors. Transfer points between conveyor sections must be designed to prevent pallet hang-ups or damage.

Throughput analysis should verify that the system can handle peak demand periods without creating bottlenecks. The conveyor speed and pallet spacing determine maximum throughput, with typical systems handling 30-100 pallets per hour per line. Accumulation zones provide buffering between operations with different cycle times, preventing upstream operations from being starved or downstream operations from being overwhelmed. Simulation modeling helps validate that the system design will meet operational requirements before installation.

Integration requirements include connections to existing systems, control interfaces, and facility infrastructure. Automated storage systems (AS/RS, shuttle systems) require precise positioning and transfer mechanisms for reliable pallet handoff. Warehouse management systems need real-time communication with conveyor controls to track pallet locations and manage routing. Electrical infrastructure must provide adequate power for drive motors and controls, typically requiring dedicated circuits and proper load management. Compressed air systems may be needed for pneumatic controls, transfers, or diverters.

Best Practices

Pallet quality standards are essential for reliable conveyor operation, particularly with roller conveyors that depend on good pallet bottom condition. Incoming pallet inspection should identify and reject damaged pallets before they enter the conveyor system. Pallet repair or replacement programs ensure that only suitable pallets are used, reducing jams and maintenance requirements. Some operations invest in standardized plastic pallets or high-quality wood pallets specifically for conveyor applications, accepting higher costs to ensure reliable operation.

Preventive maintenance programs keep systems running reliably and extend equipment lifespan. Weekly inspections should check for debris accumulation, damaged rollers or chains, and proper sensor operation. Monthly maintenance includes lubrication of chains and bearings, checking belt tension and alignment, and verifying control system operation. Quarterly professional inspections provide comprehensive assessments and identify potential issues before they cause failures. Well-maintained pallet conveyor systems can operate reliably for 15-20 years with proper care.

Zone control optimization improves system efficiency by minimizing energy consumption and reducing wear on components. Zero-pressure accumulation allows pallets to queue without contact, preventing product damage and reducing power consumption compared to live accumulation where pallets push against each other. Intelligent zone control starts sections only when needed based on pallet flow, reducing energy costs by 30-50% compared to systems that run continuously. Variable speed drives enable operators to adjust speeds based on operational conditions, optimizing performance for different products or throughput requirements.

Safety features including emergency stops, guards, and warning devices protect personnel working near conveyors. Emergency stop buttons should be accessible throughout the system, with clear procedures for safely stopping and restarting operations. Guards and barriers prevent personnel from reaching into moving conveyor sections or being struck by moving pallets. Warning lights and audible alarms alert personnel when conveyors are operating or about to start. Safety interlocks prevent conveyor operation when guards are removed or maintenance access doors are open.

Measuring Success

Key performance indicators for pallet conveyors include system uptime (target 95%+), throughput (pallets moved per hour), labor hours saved, and maintenance costs per pallet moved. These metrics help operations evaluate whether the system is delivering expected productivity benefits while maintaining reliable operation. Tracking downtime causes and jam frequency identifies opportunities for improvement in pallet quality, maintenance practices, or system design.

Return on investment typically materializes over 2-4 years through reduced labor costs, improved throughput, and better safety performance. The labor savings from eliminating forklift moves provide the largest economic benefit, with typical savings of 1-3 full-time positions per conveyor system. Increased throughput enables facilities to handle more volume without adding personnel or equipment. Reduced accident costs from improved safety lower workers' compensation expenses and insurance premiums.

Operational efficiency metrics including order cycle time, dock-to-stock time, and shipping accuracy should improve after conveyor implementation. The automated material flow reduces handling time and eliminates errors from manual routing or staging. Inventory accuracy improves as the system tracks pallet movements and locations automatically, reducing lost or misplaced inventory. Space utilization increases as the organized material flow enables better facility layout and reduces staging areas.

By implementing pallet conveyors with careful attention to load requirements, layout optimization, and maintenance practices, facilities can achieve automated material flow that reduces labor costs, improves safety, and increases throughput. The proven technology and favorable economics make pallet conveyors a foundational element of modern warehouse and manufacturing automation.

🔧Related Technologies (6)

Industrial Robotic Palletizing System for Bulk Bags

byColumbia/Okura LLC

Skateloader: Automatic One-shot Loading System

byAncra Systems

Skateloader: Automated Truck/Container Loading System with Buffer

byAncraSystems

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

ARB Pallet Layer Descrambler S400: Layer Singulation and Depalletizing

byIntralox

AMCAP: Automated Mixed Case Palletizing System

byDematic

📚Related Transport Topics

About This Topic

📁Related Projects(6)

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

MFI (implied contractor)

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions

CNH Industrial Indianapolis Distribution Center

Bastian Solutions

Amway Midwest Regional Service Center, Ada

Bastian Solutions

Roche Diagnostics Indianapolis Distribution Center

Bastian Solutions

Addverb 3PL Omnichannel Fulfillment Center

Addverb

🏢Related Suppliers(3)

Addverb

Warehouse Automation that delivers value!

Ancra Systems

Efficient Loading

Atlantic Rack

Space Solutions