Industrial Robotic Palletizing System for Bulk Bags

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

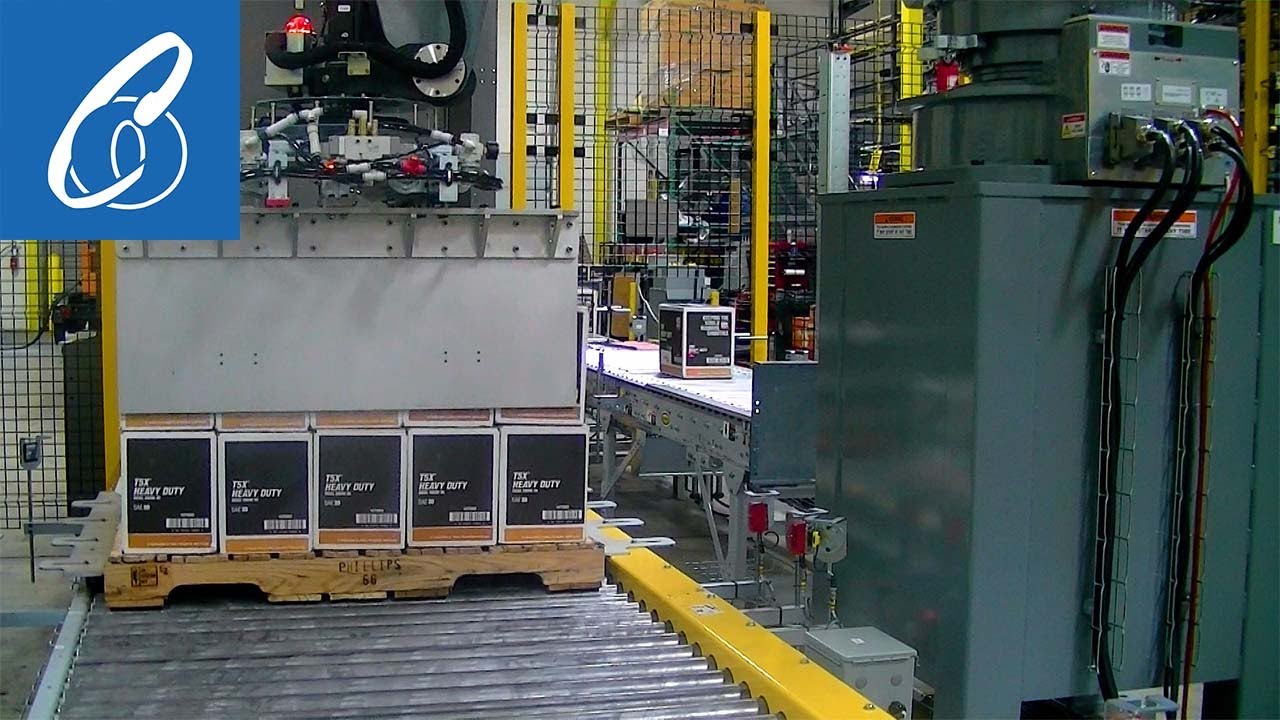

This technology focuses on automating the end-of-line process for industries that package their products in large Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags. Manually handling and stacking these heavy bags (often weighing 500-2000 kg) is labor-intensive, physically demanding, and poses safety risks. This industrial robotic palletizing system provides a fully automated solution. It is specifically engineered to pick filled bulk bags from a conveyor, often from a bagging scale, and precisely place them onto pallets in a stable pattern. The system is showcased handling milled corn but is applicable to a wide range of granular, powdered, or other free-flowing materials.

How It Works

Core Principles

The core principle involves using a heavy-duty industrial robot equipped with a custom-designed end-effector to grip, lift, and place filled bulk bags. The system automates the entire sequence from the arrival of a filled bag to the dispatch of a fully loaded pallet, integrating both palletizing and pallet conveyance.

Key Features & Capabilities

Bulk Bag Specialization: The system is distinctly designed for FIBCs, with tooling and programming optimized for their size, weight, and handling characteristics (e.g., managing bag swing, ensuring secure grips on loops).

Complete End-to-End Automation: It doesn't just place bags; it manages the entire pallet build cycle. This includes automatic pallet supply, precise bag placement for stable loads, and automatic discharge of full pallets, requiring minimal operator intervention.

Customizable Integration: A key feature is the ability to integrate optional bag conditioning equipment (like flatteners or shapers) if the product or downstream process requires it. The custom end-effectors are also tailored to the specific bag style used by the customer.

Advantages & Benefits

The most significant benefit is the removal of personnel from the dangerous task of manually handling heavy bulk bags, greatly enhancing workplace safety. It dramatically increases throughput and consistency compared to manual labor, allowing production lines to run at higher speeds. Automation also reduces the risk of product damage from improper handling and ensures pallets are built with optimal, repeatable patterns for safe transport and storage.

Implementation Considerations

Implementing such a system requires a robust foundation and ample space to handle the dynamic loads of moving heavy bags. The specific bag characteristics (loop type, dimensions, fill weight) must be well-defined for proper end-effector design. Integration with the upstream bagging machine's control system is necessary for smooth operation. The substantial weight of the bags also necessitates careful review of floor loading requirements and potential seismic considerations.

Use Cases & Applications

Ideal For

This system is ideal for any manufacturing or processing facility that produces bulk quantities of dry flowable products (e.g., flour, sugar, plastic pellets, minerals, fertilizers) and packages them in FIBCs for distribution.

Performance Metrics

Performance is measured in bags palletized per hour and system uptime. A well-designed system can operate continuously at the speed of the upstream bagging line. Key metrics include placement accuracy (for stable pallets), gripper reliability, and mean time between failures. The return on investment is heavily driven by labor savings, injury reduction, and increased throughput.

Conclusion

For producers utilizing bulk bags, automating the palletizing process is a logical and high-return investment. This industrial robotic system addresses the unique challenges of FIBC handling with strength, precision, and full automation. By implementing such a solution from integrators like Columbia/Okura, companies can achieve significant gains in safety, efficiency, and operational capacity, future-proofing their packaging lines for heavy industrial applications.