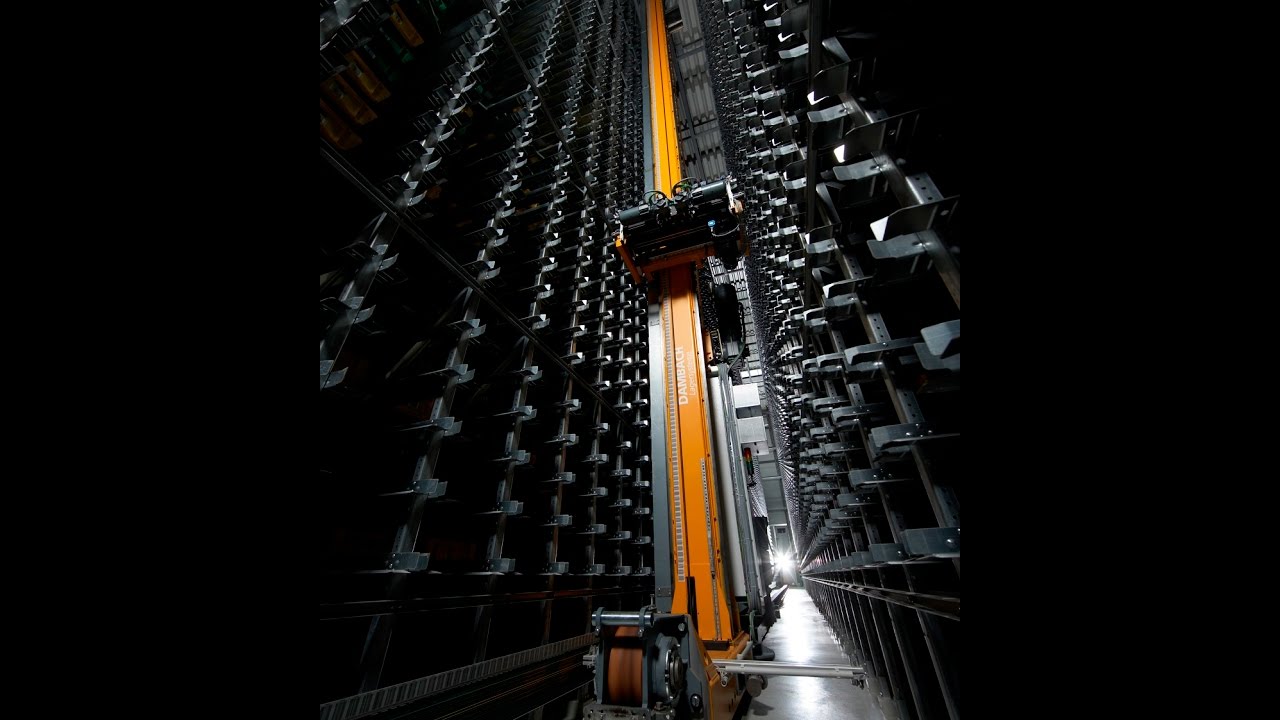

Mini Load AS/RS

Mini load AS/RS uses automated cranes to store and retrieve totes, trays, or cartons in high-density racking, providing efficient automated storage for small parts and individual items in order fulfillment operations.

Mini Load AS/RS System Overview

Core Components

- •Mini Load CraneHigh-speed S/R machine

- •Tote RackingModular storage structure

- •WCS/WMSControl & management

- •Picking WorkstationsGoods-to-person stations

Key Specifications

- •Height: Up to 50 feetVertical storage capacity

- •Aisle Width: 4-5 feetCompact design

- •Load: 50-150 lbsTotes & cartons

- •Throughput: 100-200/hrTotes per crane

Applications

- •E-commerce FulfillmentHigh-volume orders

- •PharmaceuticalRegulated storage

- •Parts DistributionAutomotive & industrial

- •Spare PartsService logistics

Key Benefits

- •3-5x Productivityvs. manual picking

- •60-80% Space Savingsvs. traditional shelving

- •99.9%+ AccuracyOrder fulfillment

- •50-70% Labor ReductionAutomated operations

Investment

- •Small: $1.5-2.5M5,000 positions, 1 crane

- •Medium: $4-8M20,000 positions, 2-3 cranes

- •Large: $10-20M50,000+ positions, 4+ cranes

- •ROI: 2-5 yearsTypical payback period

Future Trends

- •AI OptimizationPredictive slotting

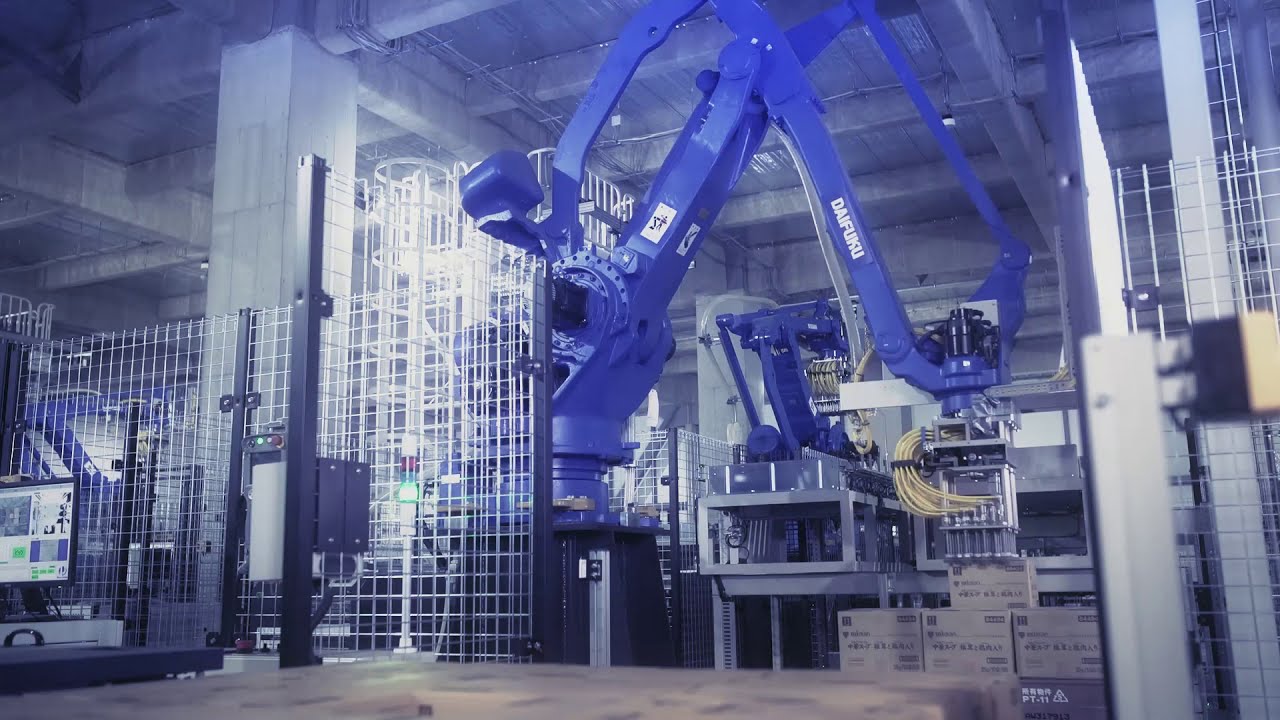

- •Robotic IntegrationAutomated picking arms

- •IoT AnalyticsReal-time monitoring

- •Modular DesignRapid deployment

How Mini Load AS/RS Works

Storage/retrieval cranes travel in narrow aisles between racking, with horizontal speeds of 400-800 feet per minute and vertical speeds of 100-200 feet per minute enabling rapid container access. The crane's load handling device uses extractors, shuttles, or vacuum systems to engage containers and transfer them between storage locations and the crane. Single-deep storage provides full selectivity with one container per location, while double-deep configurations increase density by storing two containers per position using specialized telescoping extractors.

Control systems coordinate crane movements and integrate with warehouse management systems to optimize task sequencing. Batch picking strategies group multiple orders to minimize crane travel, while zone picking divides the system into areas served by dedicated cranes. Real-time inventory tracking maintains precise records of container contents and locations, enabling accurate order fulfillment and inventory management.

Key Benefits

Labor productivity improves 3-5x compared to manual picking through automated container delivery to ergonomic picking stations. Workers remain stationary while the system delivers containers, eliminating walking and searching time. Throughput of 100-300+ lines per hour per picker far exceeds manual operations, enabling facilities to fulfill more orders with fewer personnel.

Space efficiency of 75-85% utilization enables facilities to store 2-3x more inventory in the same footprint compared to static shelving. The vertical storage to 40-60 feet maximizes building volume, while narrow aisles minimize non-productive space. Inventory accuracy exceeds 99.9% through automated tracking and controlled access.

Ergonomic benefits reduce worker fatigue and injury by presenting containers at comfortable heights (waist to chest level) and eliminating walking, bending, or reaching. The consistent work pace and reduced physical demands improve worker satisfaction and retention while reducing injury costs.

Common Applications

E-commerce fulfillment operations use mini load AS/RS as the core of goods-to-person systems, storing thousands of SKUs in totes that are automatically delivered to picking stations. Order consolidation occurs at picking stations where workers select items from multiple containers to complete orders. High throughput supports same-day and next-day delivery requirements.

Pharmaceutical distribution leverages mini load systems for storing medications and medical supplies where inventory accuracy and lot traceability are critical. The controlled access and automated tracking support regulatory compliance, while FIFO rotation ensures proper product dating. Temperature-controlled mini load systems maintain product integrity for sensitive medications.

Spare parts operations in automotive, aerospace, and industrial sectors use mini load AS/RS to manage thousands of low-velocity SKUs efficiently. The high-density storage maximizes capacity for slow-moving parts, while automated retrieval enables rapid order fulfillment when parts are needed. Kitting operations assemble parts for service orders or production.

Implementation Considerations

Building requirements include adequate ceiling height (40-60 feet preferred), floor capacity for racking loads (3,000-5,000 PSF), and proper seismic design in earthquake zones. Capital investment of $1-3 million per aisle requires careful ROI analysis, with typical payback periods of 4-7 years through labor savings and space efficiency.

Container standardization ensures reliable operation. Uniform tote dimensions simplify system design and improve flow consistency. Load weight limits (typically 50-150 pounds) must be enforced. Proper labeling with barcodes or RFID enables automated tracking and routing.

Integration with picking stations, conveyor systems, and WMS requires careful planning. Ergonomic workstation design maximizes picker productivity. Conveyor interfaces enable smooth container flow between AS/RS and picking areas. WMS integration provides real-time inventory visibility and automated task generation.

Best Practices

Slotting optimization places high-velocity items in the most accessible locations to minimize crane travel. ABC analysis guides placement decisions, with A items near I/O points and lower heights. Dynamic slotting adjusts locations based on changing velocity patterns.

Preventive maintenance including daily inspections, weekly lubrication, and monthly professional service keeps systems running reliably. Spare parts inventory enables rapid repairs. Well-maintained systems operate for 15-20 years.

Batch picking strategies group orders to minimize crane cycles. Wave picking processes orders in batches at scheduled times. Zone picking divides work across multiple pickers to maximize throughput.

Measuring Success

Key metrics include system uptime (target 98%+), picks per hour per picker (target 100-300+), inventory accuracy (target 99.9%+), and order cycle time. ROI materializes over 4-7 years through labor savings and improved productivity. Space utilization and throughput improvements validate the investment.

By implementing mini load AS/RS with attention to building requirements, container standardization, and operational integration, facilities achieve dramatic productivity improvements in order fulfillment while maximizing space utilization and inventory accuracy.

🔧Related Technologies (6)

MINI-LOAD Automated Small-Parts Storage System

byDAMBACH

Intralogistics Innovation Center: Integrated Solutions Showcase

byDaifuku

Mid-Load Automated Storage & Retrieval System (AS/RS)

by Conveyco

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

Box-IT: Ergonomic Goods-to-Person Workstation

byAddverb

About This Topic

📁Related Projects(6)

DAMBACH MINI-LOAD Automated Small Parts Storage System

DAMBACH

Lotte Korea Confectionery Centralized Distribution Center

Daifuku

Deli Group Ninghai Intelligent Logistics Center

Daifuku

F-Line Japan Major Food Distribution Center

Daifuku

Sengkang General Hospital Singapore Central Sterile Supply Unit

Daifuku

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions

🏢Related Suppliers(3)

Exotec

Elegant Solutions to Simplify Logistic Operations

Symbotic

AI-Powered Warehouse Automation Systems

Boston Dynamics

Advanced robotics company developing mobile robots for industrial automation and logistics applications.