Shuttle Systems

Shuttle systems use autonomous vehicles traveling on rails within racking structures to store and retrieve totes or cartons, providing flexible high-density automated storage with scalable throughput.

Shuttle Systems Overview

Shuttle Types

- •Pallet Shuttles2,000-4,000 lbs capacity

- •Tote ShuttlesSmaller, faster operations

- •Multi-Level ShuttlesIndependent level changes

- •4-Way ShuttlesX and Y direction movement

System Components

- •Vertical LiftsPallet/tote lifts

- •Racking Structure10-40+ positions deep

- •Control SystemWCS/WMS integration

- •Power SupplyBattery or conductor rail

Applications

- •Food & BeverageFIFO cold storage

- •E-commerceHigh-SKU fulfillment

- •ManufacturingJIT operations

- •3PL OperationsMulti-client flexibility

Key Benefits

- •80-90% Space Utilizationvs. 40-50% selective

- •Modular ScalabilityAdd shuttles as needed

- •99.9%+ AccuracyInventory precision

- •40-60% Labor ReductionAutomated operations

Investment

- •Small: $2-4M5,000 positions, 2-3 shuttles

- •Medium: $6-12M20,000 positions, 6-10 shuttles

- •Large: $15-30M50,000+ positions, 15-25 shuttles

- •ROI: 3-6 yearsTypical payback period

Future Trends

- •AI & Machine LearningPredictive optimization

- •Multi-Level ShuttlesIndependent level changes

- •IoT AnalyticsReal-time monitoring

- •Energy EfficiencyRegenerative systems

How Shuttle Systems Work

Shuttle vehicles are battery-powered autonomous robots that travel on rails mounted within the racking structure, typically at speeds of 200-400 feet per minute. Each shuttle operates on a single level, using onboard sensors and positioning systems to navigate precisely to storage locations. Load handling mechanisms including telescoping platforms, forks, or conveyors transfer containers between the shuttle and storage positions. Automatic battery charging occurs at designated stations, with shuttles managing their own charging cycles to maintain continuous operation.

Vertical lifts at the ends of aisles transport containers between levels, connecting shuttles on different floors with ground-level input/output stations. The lifts operate at speeds of 100-200 feet per minute, with multiple lifts per aisle supporting higher throughput. Control systems coordinate shuttle movements, manage traffic to prevent collisions, and optimize task sequencing to minimize travel time. Warehouse management system integration enables automated routing based on order requirements and inventory locations.

Key Benefits

Scalable throughput is the primary advantage, as facilities can add shuttles to increase capacity without redesigning the entire system. Starting with 2-4 shuttles per aisle and adding more as demand grows provides incremental investment that matches business growth. Peak season flexibility allows temporary shuttle additions to handle demand spikes, then redeployment to other areas during slower periods.

High availability results from the distributed architecture where multiple shuttles provide redundancy. If one shuttle fails, others continue operating, unlike AS/RS cranes where a single failure stops an entire aisle. Maintenance flexibility allows shuttles to be removed for service without shutting down the system, improving uptime to 99%+.

Density and flexibility combine 75-85% space utilization with the ability to handle varying container sizes and weights (typically 10-150 pounds). Mixed SKU storage in the same system supports diverse product assortments. Reconfiguration for different container types requires only software changes rather than mechanical modifications.

Common Applications

E-commerce fulfillment uses shuttle systems for high-throughput goods-to-person operations, storing thousands of SKUs in totes delivered automatically to picking stations. Scalable capacity supports seasonal peaks by adding shuttles temporarily. 24/7 operation maximizes facility utilization for rapid order fulfillment.

Retail distribution leverages shuttle systems for store replenishment, managing diverse product assortments in mixed container sizes. Batch picking for multiple stores occurs simultaneously across different levels. High throughput supports tight delivery windows for store replenishment.

Manufacturing employs shuttle systems for component storage and kitting operations. Just-in-time delivery of parts to production lines reduces work-in-process inventory. Flexible storage accommodates varying component sizes and quantities as product mix changes.

Implementation Considerations

Building requirements include 30-50 foot ceiling heights, adequate floor capacity (3,000-5,000 PSF), and proper seismic design. Modular installation allows phased implementation, starting with one aisle and expanding as needs grow. Capital investment of $1.5-4 million per aisle with typical payback of 4-6 years.

Container standardization ensures reliable operation. Uniform dimensions simplify system design, while weight limits (typically 10-150 pounds per container) must be enforced. Proper labeling enables automated tracking and routing.

Throughput planning determines shuttle quantity needed. Each shuttle handles 40-80 cycles per hour, so facilities requiring 400 cycles per hour need 5-10 shuttles per aisle. Simulation modeling validates design before installation.

Best Practices

Slotting optimization places high-velocity items near lifts and on easily accessible levels. Dynamic slotting adjusts locations based on changing demand patterns. Load balancing across levels prevents bottlenecks.

Preventive maintenance includes daily battery checks, weekly cleaning, and monthly professional service. Spare shuttle inventory enables rapid replacement during failures. Remote monitoring identifies issues before they cause downtime.

Task optimization through intelligent batching and sequencing minimizes shuttle travel. Dual-command cycles combining storage and retrieval maximize productivity. Zone management prevents shuttle conflicts and optimizes traffic flow.

Measuring Success

Key metrics include system uptime (target 99%+), throughput (cycles per hour), shuttle utilization (percentage of time productive), and inventory accuracy (target 99.9%+). ROI materializes over 4-6 years through labor savings, space efficiency, and scalable capacity. Operational flexibility and peak handling capability validate the investment.

By implementing shuttle systems with attention to scalability, container standardization, and operational integration, facilities achieve flexible high-density storage with throughput that grows with business needs.

🔧Related Technologies (6)

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

Movu Warehouse Execution System (WES): For Shuttle and AMR Management

byMovu Robotics

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

AMCAP: Automated Mixed Case Palletizing System

byDematic

HaiPick Climb System: Goods-to-Person Warehouse Automation

by Hai Robotics

RackBot™ Tote ASRS: Flexible Goods-to-Person Automation

byOthers

About This Topic

📁Related Projects(6)

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

MFI (implied contractor)

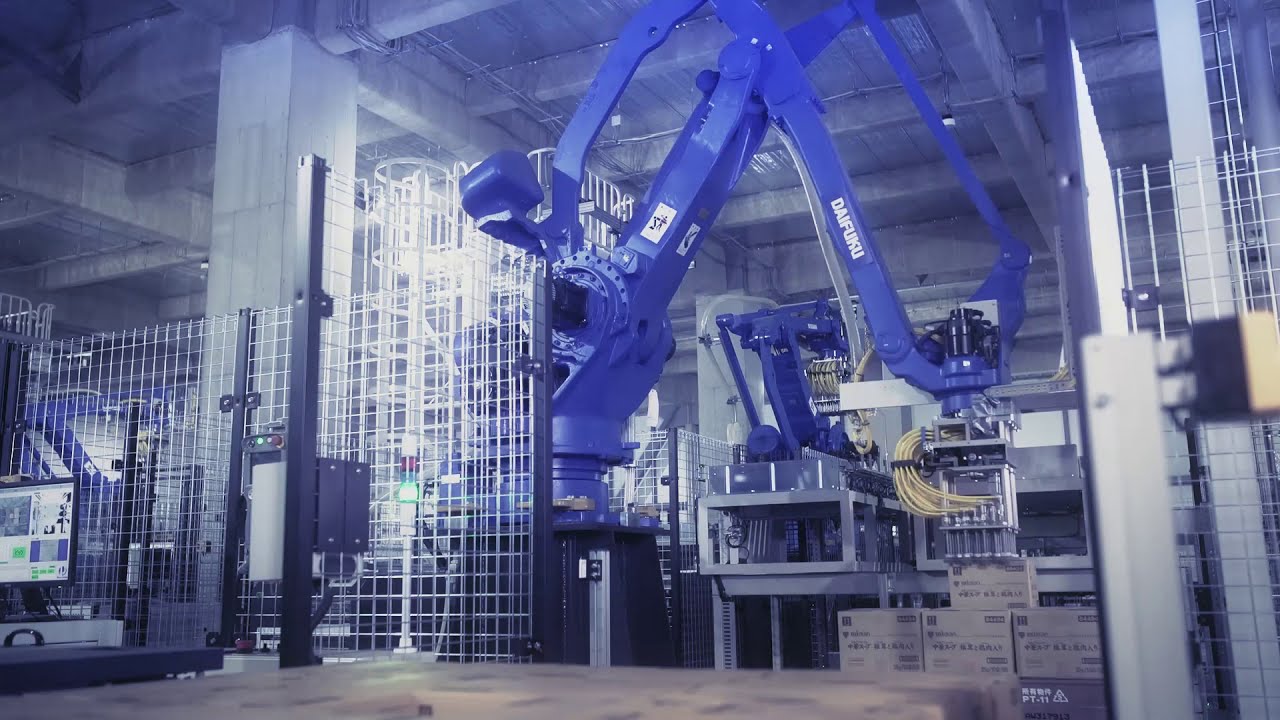

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Daifuku

Deli Group Ninghai Intelligent Logistics Center

Daifuku

F-Line Japan Major Food Distribution Center

Daifuku

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions

Landmark Group Kuwait Fulfillment Center

Addverb

🏢Related Suppliers(3)

Exotec

Elegant Solutions to Simplify Logistic Operations

Symbotic

AI-Powered Warehouse Automation Systems

Boston Dynamics

Advanced robotics company developing mobile robots for industrial automation and logistics applications.