Robotic Case Picking

Advanced robotic case picking systems that combine industrial robotics with intelligent vision systems to automate the handling of full cases and cartons, delivering exceptional speed, precision, and reliability in high-volume distribution operations.

📦 Robotic Case Picking System

Automated case-level handling with industrial-grade precision and reliability

Robotic Systems

- 6-Axis Articulated

- 4-Axis Palletizing

- Gantry Systems

- Heavy-Duty Cobots

Vision & Sensing

- 3D Vision Systems

- Barcode Reading

- Force/Torque Sensors

- Damage Detection

Gripping Systems

- Vacuum Grippers

- Mechanical Clamps

- Layer Grippers

- Custom Tools

Applications

- Food & Beverage

- Consumer Goods

- Manufacturing

- 3PL Operations

Control Systems

- Robot Controllers

- WMS Integration

- Safety Systems

- Multi-Robot Sync

Benefits

- High Throughput

- Labor Reduction

- Improved Safety

- 24/7 Operation

The Evolution of Automated Case Handling

The journey toward fully automated case picking has been driven by converging technological advances in robotics, machine vision, and artificial intelligence. Early attempts at case automation were limited by the inability of robots to reliably identify and grasp cases in the varied configurations found in real warehouse environments. Modern systems have overcome these limitations through the integration of 3D vision systems that can accurately perceive case positions and orientations, combined with adaptive gripping technology that adjusts to different case characteristics in real-time.

Today's robotic case picking systems represent mature technology capable of handling the diverse requirements of high-volume distribution operations. These systems can process cases ranging from lightweight consumer goods to heavy industrial products, adapting their approach based on case dimensions, weight, surface characteristics, and stacking patterns. The technology has evolved from specialized applications in controlled environments to flexible solutions capable of handling the complexity and variability of modern fulfillment operations.

Industrial Robot Architecture and Capabilities

At the core of robotic case picking systems are industrial-grade articulated robots specifically engineered for the demanding requirements of material handling applications. These robots typically feature six axes of motion, providing the flexibility needed to approach cases from optimal angles while navigating around obstacles and adjacent products. Payload capacities range from 50 kilograms for lighter consumer goods applications to 300 kilograms or more for heavy industrial products, with the robot's mechanical design optimized for the repetitive motion patterns characteristic of case picking operations.

The mechanical robustness of these systems is matched by sophisticated motion control technology that enables smooth, controlled movement even when handling heavy loads at high speeds. Advanced servo systems provide precise positioning accuracy, typically within 0.5 millimeters, ensuring consistent case placement and preventing damage to products or packaging. Path planning algorithms optimize robot trajectories to minimize cycle times while maintaining safe, controlled motion that prevents product damage and ensures long-term mechanical reliability.

Modern robotic case pickers incorporate comprehensive safety systems that enable them to operate in environments with human workers. Safety-rated sensors monitor the robot's workspace, automatically reducing speed or stopping motion when personnel enter designated zones. This collaborative capability allows facilities to implement robotic case picking without completely segregating automated and manual operations, providing flexibility in handling exceptions and managing variable workloads.

PackMaster: Robot-Based Mixed Case Palletizing System

Vendor: Others

Vision Systems and Intelligent Recognition

The effectiveness of robotic case picking depends critically on the system's ability to accurately perceive and understand the picking environment. 3D vision technology forms the foundation of this capability, using laser scanning, structured light, or time-of-flight cameras to create detailed three-dimensional models of pallet loads. These systems can identify individual cases within complex mixed-pallet configurations, determining precise position, orientation, and dimensions even when cases are partially obscured or irregularly stacked.

Machine learning algorithms enhance vision system capabilities by continuously improving recognition accuracy based on operational experience. These systems learn to identify cases under varying lighting conditions, recognize damaged or deformed packaging, and adapt to new product configurations without extensive reprogramming. The integration of barcode and label reading capabilities ensures accurate product identification and tracking, with the vision system able to locate and decode labels regardless of their position or orientation on the case.

Advanced vision systems employ multi-camera arrays that provide comprehensive coverage of the picking area from multiple angles. This redundancy ensures reliable case detection even in challenging scenarios where individual cameras might have obstructed views. The systems can assess pallet stability and predict how remaining cases will shift after individual picks, allowing the robot to adjust its approach to maintain safe, reliable operation throughout the depalletizing process.

Adaptive End-Effector Technology

The interface between robot and product is managed by sophisticated end-of-arm tooling designed specifically for case handling applications. Vacuum gripping systems remain the most common approach, utilizing multiple independently controlled suction zones that adapt to different case sizes and surface characteristics. Modern vacuum systems can handle cases with perforations, irregular surfaces, or varying materials by intelligently activating only those suction cups that can achieve reliable grip.

For applications where vacuum gripping is unsuitable, mechanical gripping systems provide positive engagement through clamps, fingers, or specialized fixtures. These systems use force feedback sensors to adjust gripping pressure based on case characteristics, ensuring secure handling without crushing or damaging products. The ability to sense and respond to grip conditions in real-time prevents common issues such as case slippage or deformation that can compromise picking accuracy and product integrity.

Many advanced systems incorporate quick-change tooling that allows rapid switching between different end-effector configurations to accommodate varying product mixes. This flexibility enables a single robotic cell to handle diverse case types within the same operation, maximizing system utilization and reducing the need for dedicated equipment for different product categories. Tool recognition systems automatically identify the installed end-effector and adjust robot parameters accordingly, ensuring optimal performance across different configurations.

AI-Powered Robotic Truck Loading System

Vendor: Others

Intelligent Path Planning and Optimization

Robotic case picking systems employ sophisticated algorithms that optimize picking sequences to maximize throughput while maintaining pallet stability. These systems analyze the entire pallet configuration to determine the optimal order for case removal, considering factors such as case weight, position, and the structural integrity of remaining cases. Dynamic replanning capabilities allow the system to adjust its strategy in real-time based on actual conditions encountered during picking, adapting to unexpected situations such as damaged cases or unstable stacking.

Load stability analysis ensures that case removal doesn't compromise the integrity of remaining pallet loads. The system continuously evaluates center of gravity and support conditions, avoiding picks that would cause remaining cases to shift or collapse. When necessary, the system can coordinate with automated pallet rotation equipment to reposition loads for better access to previously hard-to-reach cases, maximizing the percentage of cases that can be successfully picked without manual intervention.

Advanced systems incorporate energy optimization algorithms that minimize power consumption by selecting efficient motion paths and coordinating multiple robots to balance workload distribution. These optimizations can reduce energy costs by 15-20% compared to naive picking strategies while simultaneously improving throughput by reducing unnecessary robot motion and minimizing wait times between picks.

Integration with Warehouse Operations

Successful robotic case picking implementation requires seamless integration with broader warehouse management systems and material handling infrastructure. WMS connectivity provides real-time picking instructions and enables immediate feedback on task completion, inventory adjustments, and exception handling. The bidirectional communication ensures that warehouse management systems maintain accurate visibility into automated operations while providing robots with the information needed to optimize their performance.

Conveyor system integration enables efficient case transport from picking positions to downstream operations such as sortation, packing, or shipping. Modern systems coordinate robot picking rates with conveyor capacity to prevent bottlenecks and maintain smooth material flow. Buffer zones provide temporary storage that decouples picking operations from downstream processes, allowing the robotic system to maintain consistent throughput even when downstream operations experience temporary slowdowns.

The integration of AGV or AMR technology creates highly flexible material handling systems where mobile robots coordinate with stationary picking robots to manage pallet presentation and empty pallet removal. This coordination eliminates the need for fixed conveyor infrastructure in some applications, providing greater flexibility to reconfigure operations as business requirements evolve. Fleet management systems optimize the coordination between mobile and stationary robots, ensuring efficient resource utilization across the entire operation.

Performance Metrics and Operational Excellence

Modern robotic case picking systems deliver impressive performance metrics that significantly exceed manual operations. Typical systems achieve picking rates of 300-800 cases per hour per robot, depending on case characteristics, pallet configuration, and system design. Accuracy rates consistently exceed 99.8%, with many systems achieving near-perfect accuracy through multiple verification checkpoints including vision confirmation, weight validation, and barcode verification.

The operational consistency of robotic systems provides significant advantages beyond raw throughput numbers. Unlike manual operations where performance varies based on worker fatigue, experience, and motivation, robotic systems maintain consistent performance throughout shifts and across days. This predictability enables more accurate capacity planning and ensures reliable service levels even during peak demand periods or when facing labor availability challenges.

Uptime performance of mature robotic case picking systems typically exceeds 95%, with planned maintenance accounting for most downtime. Modern systems incorporate predictive maintenance capabilities that monitor component wear and performance degradation, scheduling maintenance activities before failures occur. This proactive approach minimizes unexpected downtime and extends equipment lifespan while reducing maintenance costs compared to reactive maintenance strategies.

Economic Considerations and ROI

The investment required for robotic case picking systems typically ranges from $200,000 to $800,000 per robot, depending on payload requirements, vision system sophistication, and integration complexity. While this represents a substantial capital commitment, the labor savings achieved through automation often justify the investment within 18-36 months. Systems can reduce direct picking labor by 60-80% while simultaneously improving throughput by 200-400%, creating compelling economics for high-volume operations.

Beyond direct labor savings, robotic case picking delivers significant indirect benefits that contribute to overall ROI. Injury reduction of 90% or more eliminates costs associated with workers' compensation claims, lost time, and productivity impacts. Improved accuracy reduces costs associated with shipping errors, returns, and customer dissatisfaction. Space efficiency improvements of 20-30% can defer or eliminate the need for facility expansion, representing substantial capital savings.

Operating costs for robotic case picking systems typically total 8-12% of initial investment annually, including maintenance, software licensing, energy consumption, and spare parts. These costs are predictable and scale linearly with system utilization, unlike labor costs which can be subject to wage inflation, benefit cost increases, and availability constraints. The long operational lifespan of 10-15 years provides extended value realization and favorable total cost of ownership compared to alternative automation approaches.

Implementation Strategy and Change Management

Successful robotic case picking implementation begins with comprehensive feasibility analysis that evaluates current operations, product characteristics, and facility constraints. Simulation modeling helps optimize system design and predict performance before committing to equipment purchases. These simulations can identify potential bottlenecks, validate throughput assumptions, and support informed decision-making about system configuration and capacity.

Phased implementation approaches reduce risk and allow organizations to develop operational expertise before full-scale deployment. Starting with a single robotic cell handling a subset of products enables teams to refine processes, train personnel, and validate performance assumptions before expanding to additional robots or product categories. This incremental approach also provides flexibility to adjust system design based on early operational experience.

Change management represents a critical success factor often underestimated in automation projects. Workforce concerns about job security must be addressed through transparent communication about how automation will affect roles and employment. Many successful implementations redeploy workers from physically demanding picking roles to higher-value activities such as exception handling, quality control, or system monitoring, creating opportunities for skill development and career advancement while maintaining employment levels.

Future Technology Directions

The evolution of robotic case picking continues to accelerate, driven by advances in artificial intelligence and machine learning. Next-generation systems will feature enhanced autonomous decision-making capabilities, learning optimal picking strategies from operational data without explicit programming. Predictive analytics will enable systems to anticipate optimal picking sequences based on historical patterns and real-time demand signals, further improving efficiency and responsiveness.

Advanced sensor technology including improved tactile feedback, enhanced 3D vision, and environmental monitoring will expand the range of products and configurations that robots can handle reliably. Collaborative robot technology will enable closer integration between human workers and robotic systems, with robots handling the most physically demanding tasks while humans manage exceptions and perform quality verification.

The integration of digital twin technology will enable comprehensive simulation and optimization of robotic picking operations, allowing continuous refinement of system performance based on virtual testing before implementing changes in production environments. Cloud connectivity will enable fleet-wide learning where improvements discovered in one facility can be automatically deployed across multiple sites, accelerating the pace of performance improvement and ensuring consistent best practices across distributed operations.

Strategic Implementation Considerations

Organizations considering robotic case picking should carefully evaluate their operational characteristics to ensure good technology fit. Systems are most effective in high-volume operations with relatively consistent case characteristics and predictable demand patterns. Operations with extreme product variability or very low volumes may find manual or semi-automated approaches more cost-effective.

Vendor selection requires careful evaluation of technical capabilities, implementation experience, and long-term support commitments. Proof-of-concept testing with actual products and operational conditions provides valuable validation of system performance before full commitment. The quality of vendor partnership significantly impacts long-term success, as ongoing optimization and system evolution require sustained collaboration and support.

Infrastructure requirements including floor loading capacity, ceiling height, power availability, and network connectivity must be carefully assessed during planning. Many facilities require modifications to accommodate robotic systems, and these costs should be included in total project budgets. Safety system integration including guarding, emergency stops, and personnel detection must meet applicable regulations while supporting efficient operations.

The future of case picking in high-volume distribution operations is increasingly automated, with robotic systems playing a central role in enabling the speed, accuracy, and efficiency that modern commerce demands. Success requires careful planning, realistic expectations, and commitment to ongoing optimization, but the operational and economic benefits make robotic case picking an increasingly compelling choice for organizations seeking to build competitive advantage through warehouse automation.

🔧Related Technologies (6)

PackMaster: Robot-Based Mixed Case Palletizing System

byOthers

AI-Powered Robotic Truck Loading System

byOthers

Modula Horizontal Carousel (HC): Goods-to-Man Picking Solution

byModula

Modula Flexibox: Next-Generation Automated VLM Picking Solution

byKardex

The FD System: Dynamic Multi-Shuttle Case Handling AS/RS

byDematic

RoboShuttle Goods-to-Person System: High-Efficiency Warehouse Automation

byGeek+

📚Related Picking Topics

About This Topic

📁Related Projects(6)

MRG - Retail Distribution Center Automated Goods-to-Person Intralogistics

psb intralogistics GmbH

JD.com - Flexible Case Picking Automation with ForwardX Robotics AMRs

ForwardX Robotics

Alza Prague High-Throughput Fulfillment Center

Element Logic

Landmark Group Kuwait Fulfillment Center

Addverb

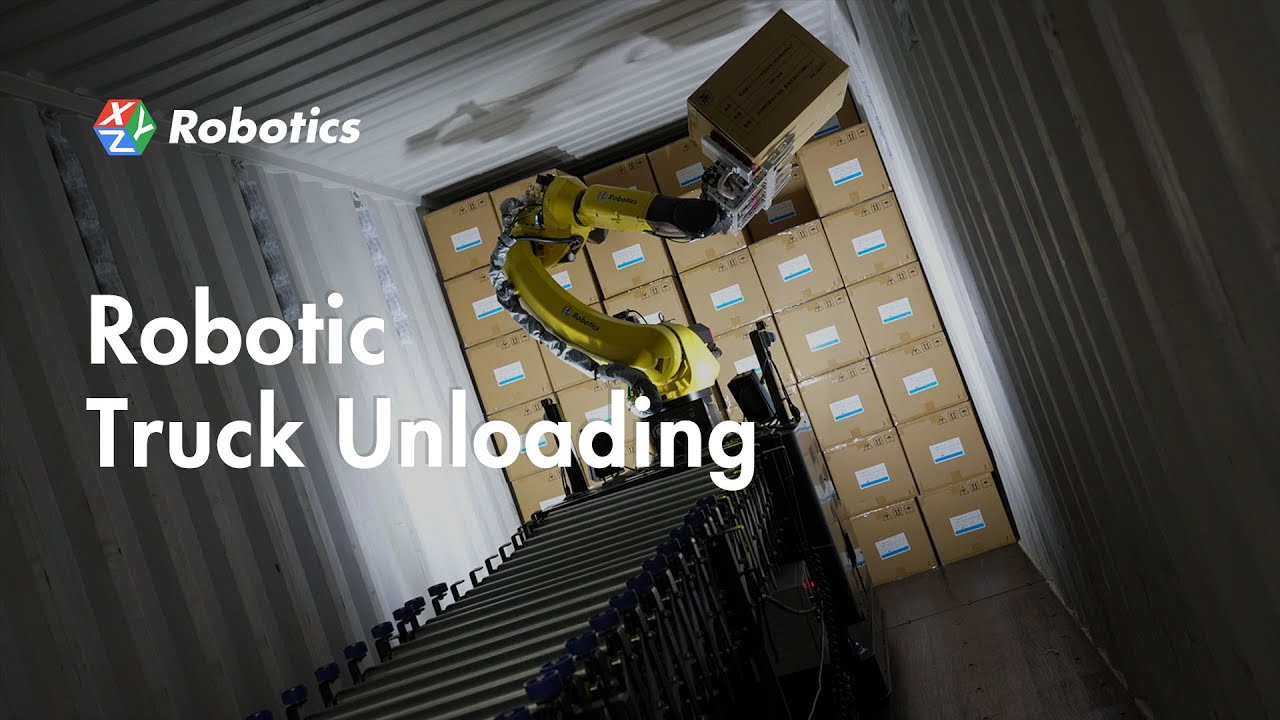

XYZ Robotics - Japanese 3PL Warehouse Robotic Truck & Container Unloading Project

XYZ Robotics

Dexterity AI & FedEx Parcel Hub Robotic Truck Loading Project

Dexterity AI

🏢Related Suppliers(3)

6 River Systems

The Seamless Fulfillment Automation Solution to Boost Efficiency and Productivity in Your Warehouse

Addverb

Warehouse Automation that delivers value!

AutoStore

The World's Fastest AS/RS Solution