Mini-Load AS/RS: Automated Storage and Retrieval for Small Loads

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

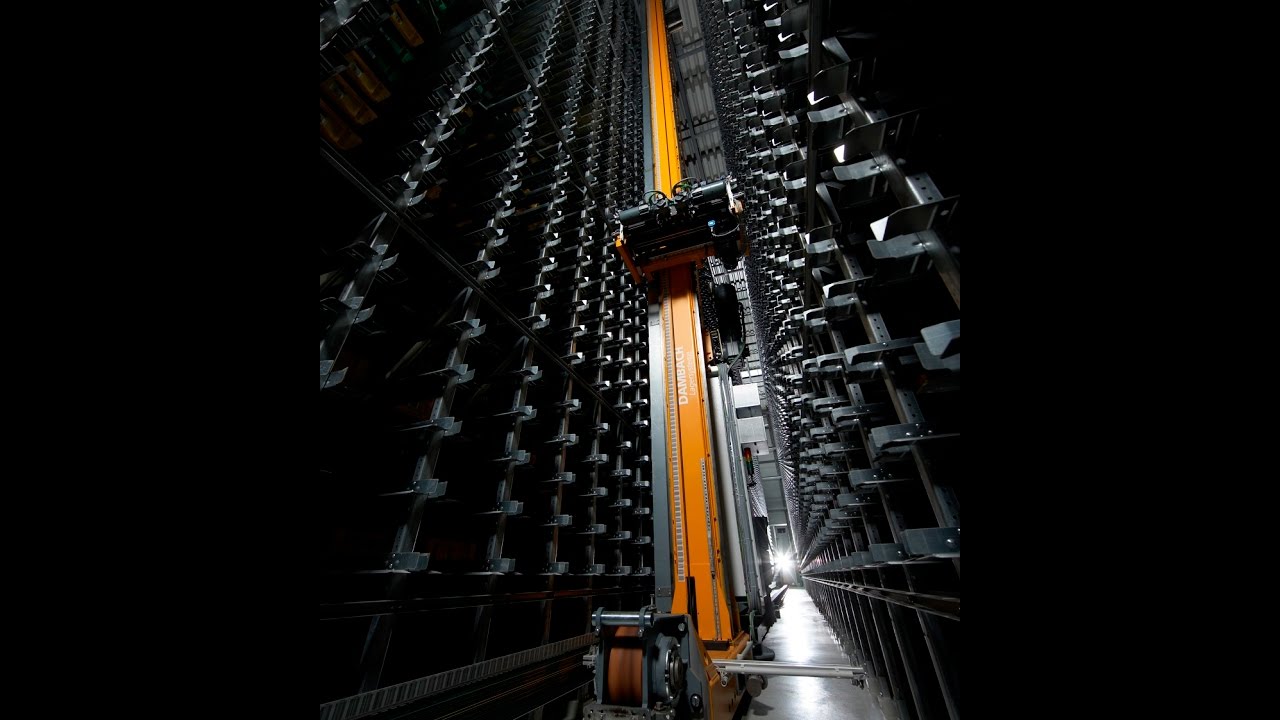

Mini-Load Automated Storage and Retrieval Systems (AS/RS) are a category of warehouse automation specifically engineered for the efficient handling of small unit loads, such as individual totes, cartons, or cases. These systems automate the core functions of storing and retrieving inventory within a high-density rack structure, replacing manual forklift operations in narrow aisles. By utilizing computer-controlled cranes or shuttles, they achieve high speeds and precise positioning, which directly translates to improved operational accuracy and throughput. A significant secondary benefit is the transformation of the work environment; by removing internal combustion or electric lift trucks from storage aisles, these systems notably reduce noise pollution and eliminate a major source of potential accidents, contributing to a safer and more pleasant workplace.

How It Works

Core Principles

The system operates on the principle of automated, vertical storage and retrieval. A dedicated storage/retrieval machine (SRM), such as a stacker crane, operates within a single aisle of multi-level racking. It is directed by a warehouse control system (WCS) to automatically store incoming loads and retrieve specific items or totes as needed for order fulfillment.

Key Features & Capabilities

High-Speed Precision Handling is a defining feature. The electrically driven stacker cranes can move rapidly horizontally and vertically with pinpoint accuracy, ensuring items are retrieved and stored correctly on the first attempt, which is foundational for the system's accuracy claims.

Dense Storage Configuration maximizes cubic space. The system utilizes very narrow aisles (often just wide enough for the crane) and the full available height of the facility, allowing for a much greater storage capacity within a given footprint compared to traditional shelving or wide-aisle racking.

Software-Driven Inventory Management provides direct control. Every storage and retrieval transaction is executed and recorded by the WCS, which maintains real-time knowledge of every item's location, enabling accurate order fulfillment and inventory tracking.

Advantages & Benefits

The primary advantage is a dramatic improvement in picking and inventory accuracy. By automating the retrieval process and using precise digital control, human error in selecting the wrong item or location is virtually eliminated, leading to higher customer satisfaction and reduced costly returns.

It creates a significantly safer and quieter work environment. Removing forklifts from storage aisles eliminates risks associated with collisions, tipping, and pedestrian interactions. The shift to electrically operated cranes also drastically reduces ambient noise levels.

The system increases storage density and operational throughput. By making full use of vertical space and automating travel and search times, it allows for more inventory to be held on-site and enables faster response to order requests, supporting just-in-time operations.

Implementation Considerations

Implementing a Mini-Load ASRS requires a substantial upfront capital investment in hardware, software, and often facility modifications (e.g., reinforcing floors for heavy racking, ensuring adequate ceiling height).

System design and integration are complex. The system must be carefully sized for current and future throughput and storage needs. Seamless integration with existing Warehouse Management Systems (WMS), conveyors, and picking workstations is critical for realizing its full benefits.

While reducing labor in the aisles, it creates a need for different technical skills related to system monitoring, maintenance, and control room operation, necessitating workforce training and change management.

Use Cases & Applications

Ideal For

This technology is ideal for e-commerce fulfillment centers, pharmaceutical warehouses, electronics distribution, and any operation that manages a high volume of SKUs in small packages and requires fast, flawless order accuracy to meet service level agreements.

Performance Metrics

While specific numerical metrics (e.g., transactions per hour) are not provided in the given text, the content emphasizes qualitative performance gains: improved picking accuracy, increased speed, and the creation of a safer, quieter environment. The elimination of lift trucks is a key measurable change in equipment usage and associated risk factors.

Conclusion

The Mini-Load AS/RS is a proven and powerful automation solution for warehouses seeking to overcome the challenges of accuracy, space, and safety. It transforms the storage function from a manual, potentially hazardous operation into a precise, high-speed, and software-controlled process. For businesses experiencing growth in order volume, complexity, or facing labor and safety challenges, investing in a Mini-Load system can provide a solid foundation for efficient and scalable operations. Success depends on thorough needs analysis, expert system design, and a commitment to integrating the technology deeply into the warehouse's workflow and systems architecture.

📦Related Projects

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.