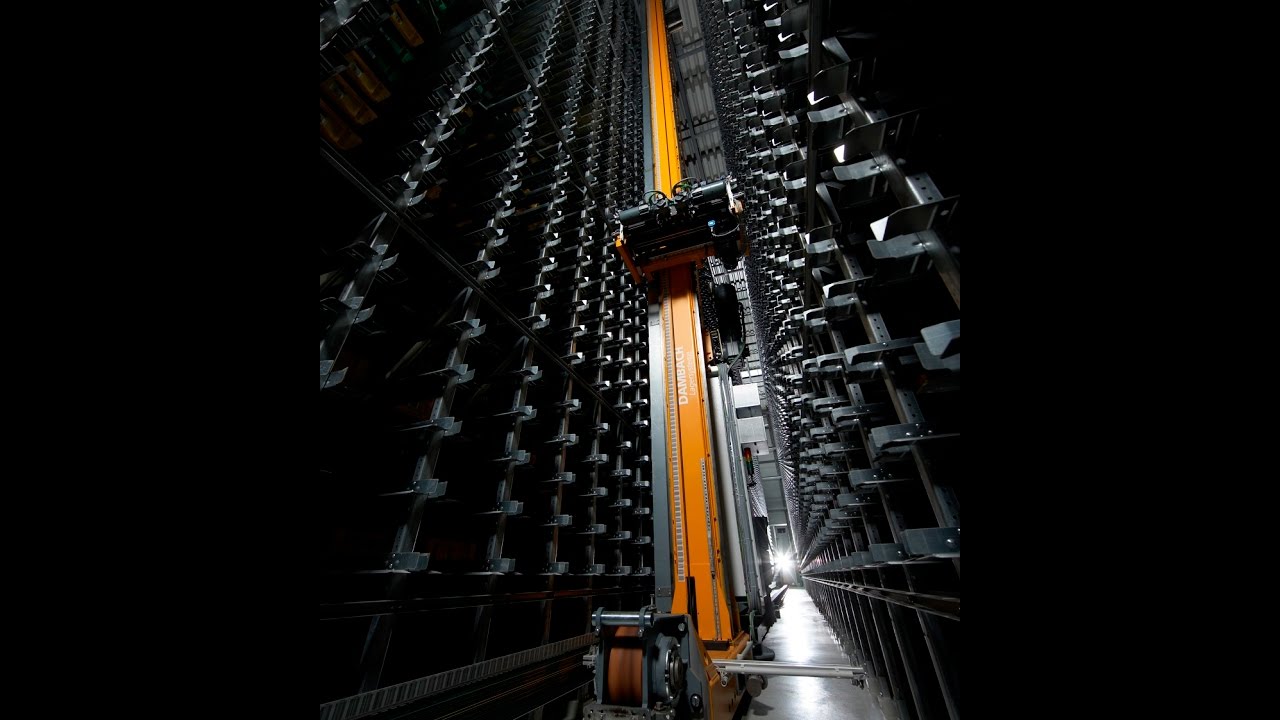

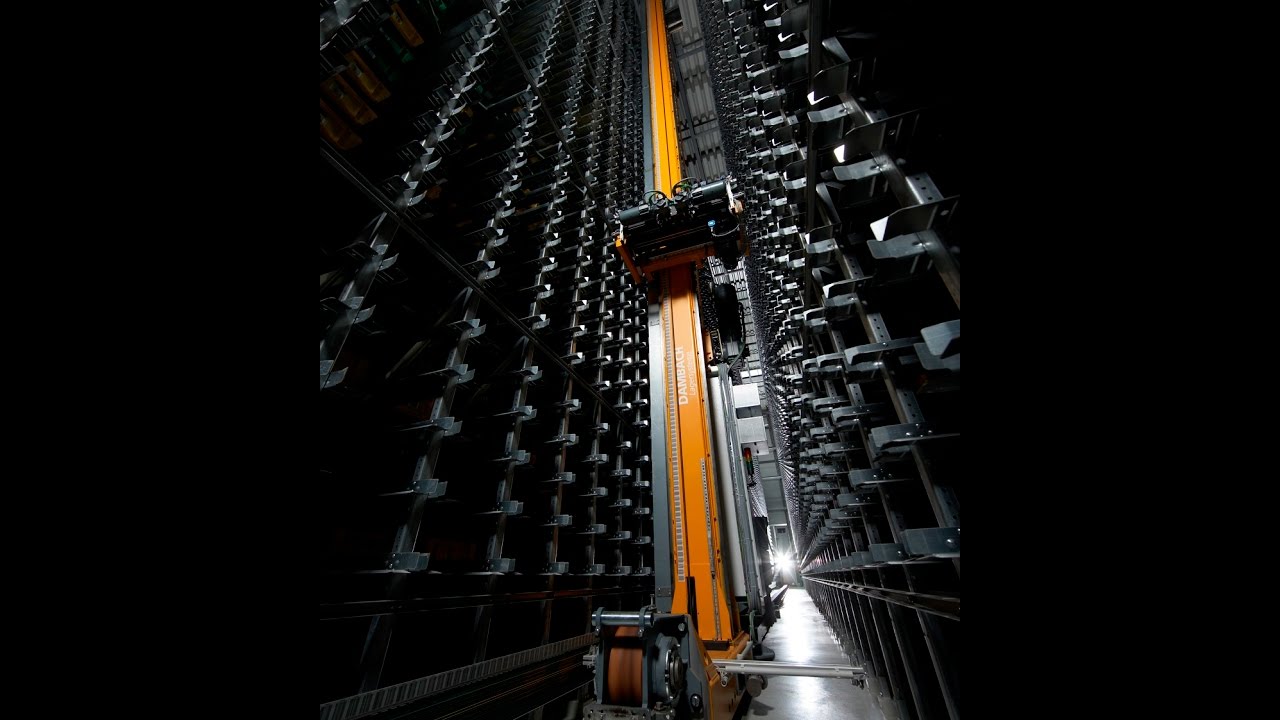

MINI-LOAD Stacker Cranes: High-Bay Storage for Small Loads

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

DAMBACH MINI-LOAD stacker cranes are a specialized category of automated storage and retrieval systems engineered for handling small unit loads within exceptionally high storage structures. These systems are designed to maximize vertical space utilization, operating at heights up to 27 meters, which is a defining characteristic for achieving ultra-high-density storage. They are built to handle a variety of container types, including standard trays and special custom containers, with payloads up to 300 kilograms. The combination of high operational speeds, robust construction, and flexible load-handling options makes these cranes a core component in automated warehouses for industries that manage large inventories of small items, such as automotive parts, electronics, or pharmaceutical supplies, where space efficiency and fast access are paramount.

How It Works

Core Principles

The system operates on the principle of a rail-guided, computer-controlled stacker crane that moves within a single aisle of high-bay racking. It performs fully automated cycles of storing incoming loads and retrieving requested items, traveling horizontally along the aisle and moving its load-handling device vertically to access specific storage locations.

Key Features & Capabilities

High-Bay Operation (up to 27m) is the standout feature, allowing warehouses to exploit unused vertical air space to an extreme degree. This dramatically increases storage capacity within a fixed footprint, making it ideal for facilities with limited floor space but available height.

High Throughput and Flexible Load Handling are combined strengths. The cranes are engineered for rapid horizontal and vertical movement. Coupled with a selection of load-handling devices (telescopic forks for pallets/trays, box grabs for specific containers), they can efficiently service a wide range of product and container types.

Durable Construction and Configurable Design ensure longevity and adaptability. Built for reliability in continuous operation, the cranes are offered in one or two-mast versions to handle different load sizes and stability requirements, and are designed with small approach dimensions to minimize the aisle footprint.

Advantages & Benefits

The primary advantage is exceptional storage density and space savings. By building upwards to 27 meters, the system can store a vastly greater number of containers compared to conventional shelving or lower ASRS systems, potentially eliminating the need for facility expansion.

It delivers high-speed material flow to support production or order fulfillment. The impressive throughput rates ensure that requests for parts or materials are fulfilled quickly, reducing wait times and keeping downstream processes running efficiently.

The system offers application flexibility through customizable handling. The ability to equip the crane with different grabs or forks means the same core system can be adapted to handle various container styles and storage depths (single or double-deep), protecting the investment against future changes in packaging or processes.

Implementation Considerations

Implementing a 27-meter high system is a major structural undertaking. The building must have adequate ceiling height and the floor must be engineered to support the significant weight of the full racking system. Retrofitting an existing building may be challenging or impossible.

Precise integration of the load-handling device with the specific containers used is crucial for reliable operation. This requires detailed planning and potentially custom tooling, which must be factored into the project timeline and cost.

While automated, the system requires specialized maintenance access for equipment at great heights. Planning for safe maintenance procedures, platforms, and potentially integrated service lifts is an important part of the design phase.

Use Cases & Applications

Ideal For

This technology is ideal for manufacturing plants with centralized parts storage (e.g., automotive, aerospace), large distribution centers for small parts (e.g., electronics, industrial supplies), and any operation with a vast SKU count of small items where maximizing storage density and ensuring fast, accurate retrieval is critical.

Performance Metrics

Key performance specifications from the content include:

- Maximum Storage Height: Up to 27 meters.

- Maximum Load Capacity: Up to 300 kilograms.

- Key Performance Attribute: High throughput rates (specific numbers not provided but emphasized).

Conclusion

DAMBACH MINI-LOAD stacker cranes represent the high-end of vertical density for small-load AS/RS. They are a powerful solution for operations that have exhausted their floor space and must look upwards to accommodate growth. The combination of extreme height, respectable load capacity, and high speed makes them a productivity workhorse for demanding storage and retrieval applications. Investing in such a system is a significant decision that requires thorough feasibility studies regarding facility suitability, container standardization, and throughput needs. For the right application, however, it delivers an unmatched combination of space savings, inventory control, and automated efficiency, forming the dense, high-speed backbone of a modern automated warehouse.

📦Related Projects

DAMBACH MINI-LOAD Automated Small Parts Storage System

The DAMBACH MINI-LOAD system is an automated storage and retrieval machine for small parts, achieving heights up to 27 meters and high throughput for container and carton storage.

LIEKEN High Bay Cold Store for Baked Goods

A high bay cold store for bread and baked goods with a capacity of 6,000 pallets at -24°C, using DAMBACH Storage and Retrieval Machines to achieve 4,296 pallet movements daily.

Dongfeng Motor R&D Center Smart Logistics Warehouse

A compact 470㎡ intelligent warehouse with 15-level high-density storage supporting 10,000+ SKUs for automotive R&D supply chain optimization.