Our Curated Projects

38 projects

San Francisco International Airport Harvey Milk Terminal 1 Baggage Handling System

SFO partnered with BEUMER Group to deploy the United States' first Individual Carrier System (ICS) baggage handling system, enhancing efficiency and security in the new terminal.

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

Coles Redbank Automated Distribution Center

Coles' largest capital investment in 109 years: a 66,000 sqm automated distribution center in Redbank processing 4 million cases weekly for 219 supermarkets.

Didactic - Normandy France Healthcare Storage Expansion with Pallet Shuttle

Mecalux designed a customized semi-automatic Pallet Shuttle solution for Didactic (Normandy, France) to address 92% storage capacity utilization, delivering 11,000 pallet capacity with FIFO/LIFO functionality for medical device distribution.

DPD Warszawa - Poland Logistics Center Parcel Sorting Automation

DPD Warszawa implemented BEUMER Group's BG Line Sorter at its Poland logistics center, delivering 1,500-10,000 items/hour throughput with active slat-belt technology for diverse parcel handling.

Dongfeng Motor R&D Center Smart Logistics Warehouse

A compact 470㎡ intelligent warehouse with 15-level high-density storage supporting 10,000+ SKUs for automotive R&D supply chain optimization.

Ariat Wholesale Footwear & Apparel Order Fulfillment Center

A wholesale footwear and apparel brand automated order consolidation with the EuroSort Twin Push Tray Sorter, integrating Exotec and Geek+ robotic picking to process up to 16,000 items per hour.

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions, a Toyota Advanced Logistics company since 2017, leverages Toyota Production System principles like Jidoka to deliver intelligent automation and supply chain integration.

PUMA Indianapolis East Coast Distribution Center

PUMA, NFI/Cal Cartage, and Bastian Solutions deployed North America's largest AutoStore Black Line system, increasing capacity 10x and reducing delivery times from 8 days to 2 days.

Balluff Inc. Sensor Solutions Automated Warehouse

Balluff Inc. achieved a 177% throughput increase with an AutoStore system implemented by Kardex, featuring an innovative cross-building design installed in just 6 months.

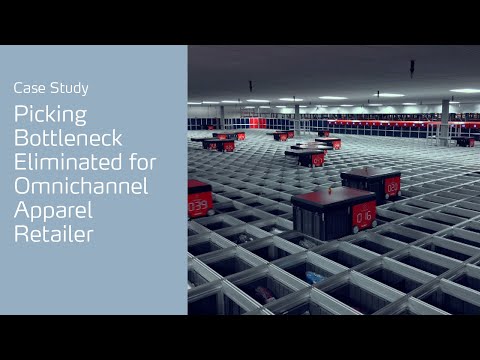

Cutter & Buck Seattle Apparel Fulfillment Center

Cutter & Buck deployed an AutoStore system with 34,000 bins and 54 robots, implemented by Kardex, to streamline apparel fulfillment, reduce storage footprint by 50%, and achieve order turnaround in under 10 minutes.

Addverb 3PL Omnichannel Fulfillment Center

Addverb transformed a 330,000 sq. ft. 3PL facility with integrated fixed and flexible automation, enabling seamless B2B and B2C operations and a dispatch of 100,000 pieces daily.

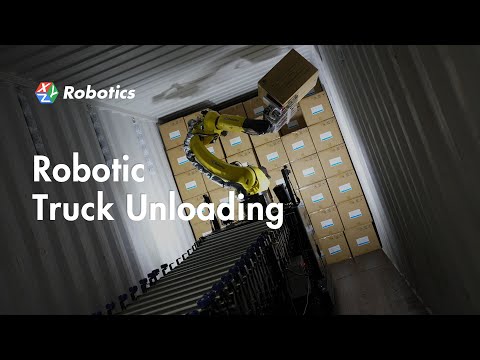

XYZ Robotics - Japanese 3PL Warehouse Robotic Truck & Container Unloading Project

XYZ Robotics deploys RockyOne Mobile Manipulation Robot to automate truck and container unloading for a Japanese 3PL warehouse, handling 15-kg cartons in 40-ft containers within 2 hours.