Hirschmann Automotive Rankweil Production Logistics

⭐Key Features

- •46 ARC5 transport robots (expandable to 74)

- •Fully automated connection of 40 injection molding machines

- •Automated high-bay warehouse with 42,000 storage locations

- •Just-in-time material provisioning throughout value chain

- •Energy-efficient operation under 150 watts

- •Seamless ERP and MES system integration

- •Three-shift operation capability

📊Results & Benefits

- ✓11,000 container transports daily in three-shift operation

- ✓18,000 km annual travel distance per transport robot

- ✓Maximum transparency and minimal friction losses

- ✓Complete control over material flow

- ✓Scalable system architecture for future requirements

🎯Challenges & Solutions

Integrating material flows into a single powerful system for maximum efficiency

Implemented fully automated customized intralogistics system connecting production and logistics

Reducing manual interventions and transport effort

Deployed 46 ARC5 transport robots and automated high-bay warehouse

📝Project Overview

Project Overview

Hirschmann Automotive faced the critical challenge of integrating their material flows into a single, powerful system to ensure maximum efficiency in production logistics at their Rankweil facility. Operating within the competitive European economic landscape, the company needed a solution that could seamlessly connect production and logistics while meeting the highest standards of operational efficiency.

The project was developed through intensive workshops with Servus Intralogistics, who served as partners throughout the entire project lifecycle. Based on fact-based analysis, they collaboratively developed a vision that has now been implemented - a fully automated, customized intralogistics system specifically tailored to Hirschmann Automotive's requirements.

The solution represents production logistics at a new level, creating a perfect symbiosis of technology, efficiency, and future viability that sets new standards in automotive manufacturing logistics.

Technical Solution

ARC5 Transport Robot Fleet

The system features 46 ARC5 transport robots that handle all supply logistics, with the capacity to expand to 74 robots as needed. Each transport robot covers approximately 18,000 kilometers annually, demonstrating the extensive material movement requirements of the facility. These autonomous vehicles operate efficiently with energy consumption under 150 watts during normal operation.

Automated Guided Vehicles (AGVs): Comprehensive Warehouse Automation

Vendor: Jungheinrich

Key Features

The fully automated connection of 40 injection molding machines enables direct transfer of finished parts from production to storage without manual intervention, creating a seamless manufacturing-to-logistics pipeline.

The energy-efficient design of the ARC5 transport robots, consuming less than 150 watts during operation, combines high performance with sustainability, supporting the company's environmental and efficiency objectives.

The scalable system architecture allows for future expansion from the current 46 transport robots to 74, providing flexibility to accommodate growing production demands and changing requirements.

Results & Benefits

The system handles approximately 11,000 container transports daily across three shifts, demonstrating the high-volume capability required for automotive production logistics operations.

Maximum transparency and minimal friction losses have been achieved throughout the material flow, providing complete control over logistics processes and enabling continuous optimization.

The just-in-time material provisioning throughout the entire value chain reduces manual interventions and transport effort while ensuring production efficiency and material availability.

Challenges & Solutions

The primary challenge of integrating diverse material flows into a single, powerful system for maximum efficiency was addressed through the implementation of a fully automated, customized intralogistics system that seamlessly connects production and logistics operations.

The need to reduce manual interventions and transport effort was successfully met through the deployment of 46 ARC5 transport robots and an automated high-bay warehouse, creating a hands-off logistics environment.

System Integrator

Servus Intralogistics served as the system integrator throughout the entire project lifecycle, from initial workshops and fact-based analysis to final implementation. Their partnership approach and expertise in customized intralogistics solutions enabled the successful creation of this advanced production logistics system that sets new standards in automotive manufacturing efficiency.

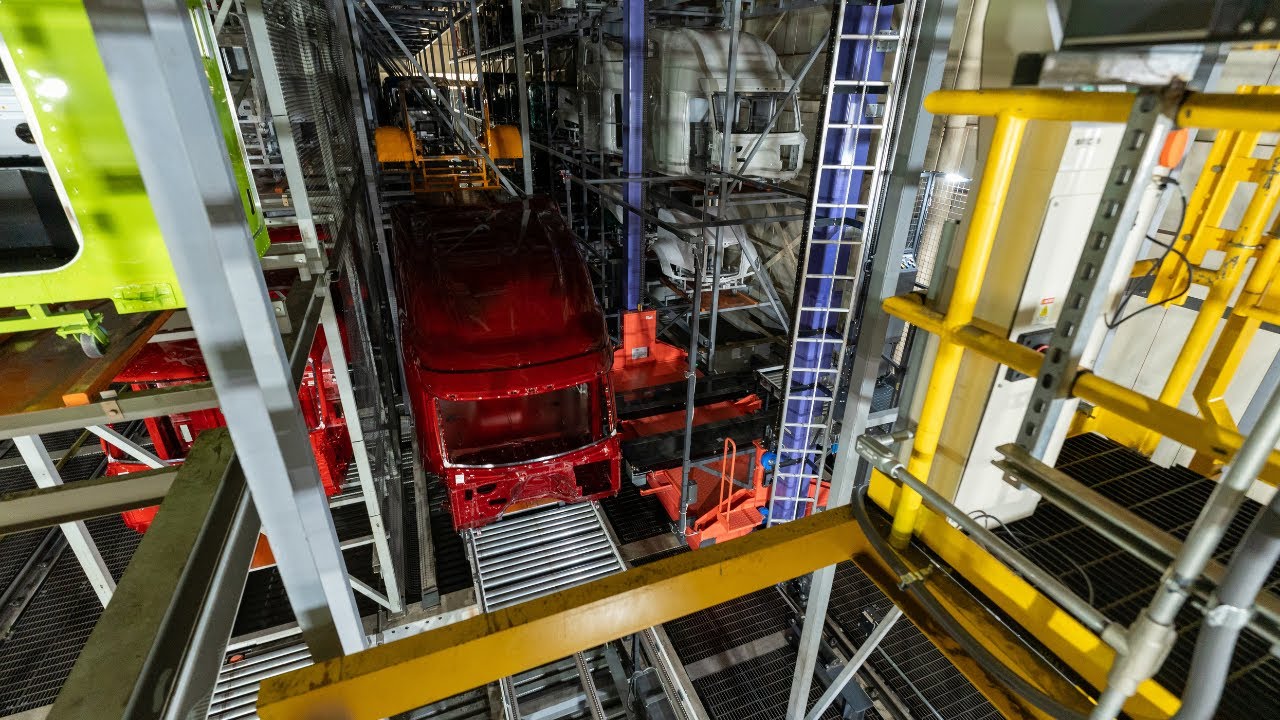

🖼️Project Gallery

🔧Related Technologies (6)

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

Piolax Canton Georgia Automotive Parts Distribution Center

byDaifuku

AMR/AGV Tuggers: Autonomous Towing for Trailers and Trolleys

by VisionNav Robotics

Tugger AGV: High-Capacity Automated Tugger for Indoor and Outdoor Transport

byOthers

AGV Systems: Custom Turnkey Tugger Solutions

byROBOS

Automated Guided Vehicle (AGV) Systems: Safety-First Automation

byJungheinrich

📚Related Knowledge Articles (4)

AGV Tugger

AGV tuggers are automated guided vehicles that tow trains of carts or trailers through warehouses and manufacturing facilities, efficiently moving large volumes of materials along fixed routes.

Production Logistics Strategy

Production logistics orchestrates the seamless flow of materials, components, and finished goods within manufacturing operations. From just-in-time delivery to line-side replenishment, master the strategies that keep production lines running efficiently while minimizing inventory and maximizing throughput.

Manufacturing & Industrial Warehousing

Manufacturing warehousing supports production operations with just-in-time material delivery, requiring tight integration with production systems and flexible automation that adapts to changing manufacturing schedules.

Multi-Robot Orchestration

Intelligent fleet management systems that coordinate multiple autonomous robots to work together efficiently, optimizing task allocation, traffic management, and resource utilization across complex warehouse environments.