dm-drogerie markt Weilerswist Logistics Center Packaging Line

⭐Key Features

- •BEUMER stretch hood® S high-performance packaging systems

- •Ultrasonic pallet height measurement for fully automated adaptation to varying stack heights

- •Ultra-thin (60-micrometer), recyclable stretch film for material efficiency

- •Energy consumption of only 0.04 kilowatt-hours per pallet

- •Systems custom lacquered in multiple colors to match dm's distribution center design

- •Packaging protects goods on five sides without additional film sheets or wrapping film

- •High system availability, noted as superior to traditional stretch wrapping systems

📊Results & Benefits

- ✓Each system handles 90 pallets per hour (slightly under the 100/hour design capacity)

- ✓Processes 2,500 to 3,000 pallets daily for shipment

- ✓Achieves impeccable operational performance since commissioning in summer 2010

- ✓Creates a stable, secure pallet load protected from weather, dust, and moisture

- ✓Improves goods visibility due to the smooth, transparent film hood

- ✓Significantly reduces packaging material use with thin, recyclable film

🎯Challenges & Solutions

Needing a high-speed, reliable, and secure packaging solution for a massive volume of palletized goods (2,500-3,000 daily) at a central distribution center serving numerous stores.

Implemented multiple BEUMER stretch hood® S high-performance systems, each capable of handling 90 pallets per hour with high availability, automating the entire pallet packaging process from height detection to sealing.

Requiring packaging that protects diverse palletized goods for transport to stores while optimizing material use, energy consumption, and integrating into the facility's aesthetic.

The BEUMER stretch hood system uses ultrasonic measurement to calculate the ideal amount of ultra-thin (60µm), recyclable film for each pallet, consumes minimal energy (0.04 kWh/pallet), and the machines were custom-colored to match the facility's design, providing secure 5-side protection.

📝Project Overview

Project Overview

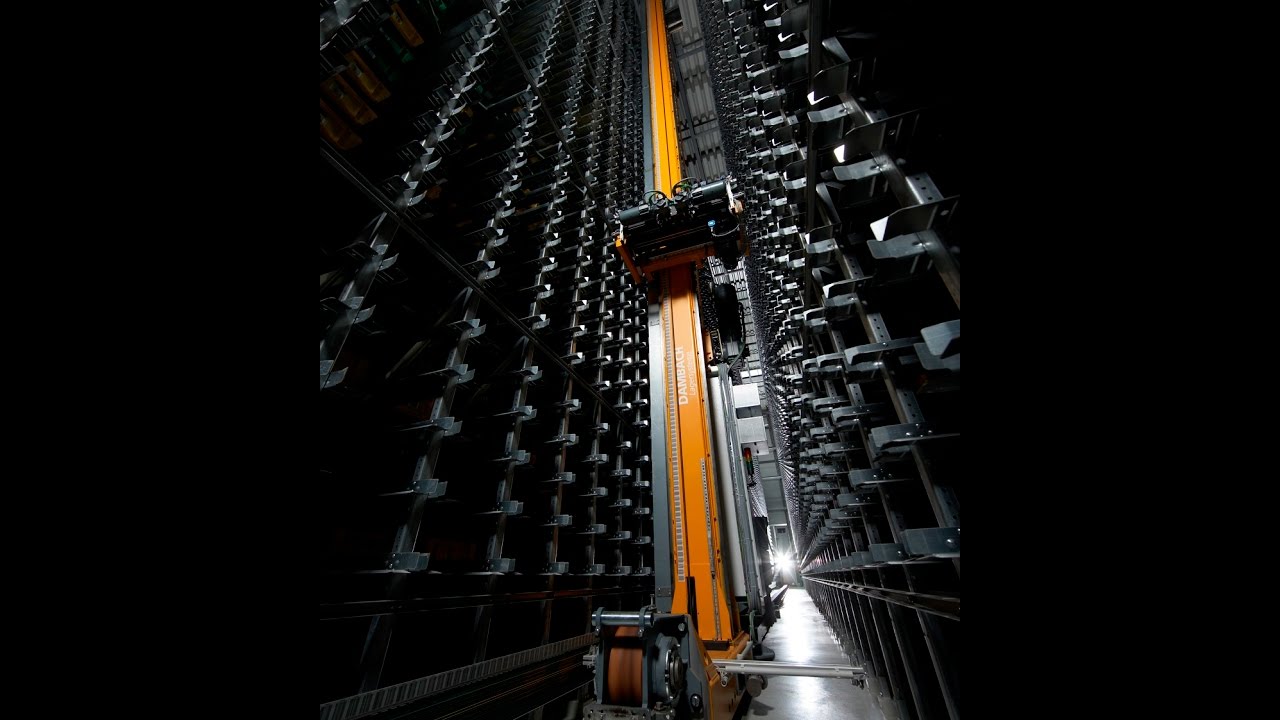

dm-drogerie markt, a leading German drugstore chain, commissioned a new, highly advanced central logistics center in Weilerswist, near Cologne. This massive 65,000-square-meter facility serves as the primary distribution hub for supplying the company's extensive network of individual stores. A critical requirement for this operation was a packaging technology solution that could securely prepare a high daily volume of palletized goods for transportation, ensuring products arrived at stores undamaged and protected from the elements.

The packaging process needed to be fast, reliable, and efficient to match the throughput of one of Europe's most advanced logistics centers. dm-drogerie markt turned to BEUMER Group to implement a state-of-the-art pallet packaging solution that would meet these high demands for performance, security, and operational efficiency.

Technical Solution

BEUMER stretch hood® S High-Performance Systems

The core of the solution is the installation of BEUMER stretch hood® S packaging machines. These systems are designed for high-volume operations, with a theoretical capacity of 100 pallets per hour. At the Weilerswist center, each system consistently handles 90 pallets per hour.

Robotic Palletizing with Multi-Pick End Effector

Vendor: Columbia/Okura LLC

Key Features

The system's automation is driven by ultrasonic height sensing, enabling true hands-off operation for variable pallet loads. Its use of ultra-thin, recyclable film represents a significant advancement in material efficiency and sustainability compared to traditional thicker wraps.

The stretch hood technology itself provides superior protection by creating a tight, tense film cover on five sides, forming a stable unit with the load carrier. The smooth surface of the hood also improves the visibility of the packaged goods. The systems are noted for their exceptional reliability and higher availability compared to conventional stretch wrapping machines.

Results & Benefits

The packaging line successfully meets the high-volume demands of the central distribution center, processing between 2,500 and 3,000 pallets daily for shipment. Each line operates at a high rate of 90 pallets per hour and has performed impeccably since its commissioning in the summer of 2010.

The packaged pallets are extremely stable and secure for transit, protected against weather, dust, and moisture. The solution also delivers significant operational benefits: reduced material usage through optimized thin film, very low energy consumption, and high system uptime. The custom-colored machines demonstrate a unique attention to detail, aligning industrial functionality with facility design.

Challenges & Solutions

The primary challenge was securing a massive and continuous daily flow of diverse palletized goods for store delivery with a fast, reliable, and resource-efficient method. BEUMER Group's stretch hood® S systems provided the solution, offering high-speed, fully automated packaging with superior protective qualities and notable energy and material savings.

A secondary challenge involved integrating heavy industrial machinery into a modern, designed logistics environment. dm's request for custom-colored machines was accommodated by BEUMER, resulting in packaging systems that fit perfectly within the facility's aesthetic, proving that functionality and design can coexist in an industrial setting.

System Integrator

BEUMER Group served as the system provider and integrator for this advanced packaging solution. They supplied the stretch hood® S high-performance systems, customized them to dm's color specifications, and integrated them into the pallet handling workflow of the new Weilerswist logistics center. Their technology has been central to the reliable, high-volume packaging operation that supports dm-drogerie markt's extensive retail network.

🔧Related Technologies (6)

Robotic Palletizing with Multi-Pick End Effector

byColumbia/Okura LLC

Industrial Robotic Palletizing System for Bulk Bags

byColumbia/Okura LLC

Automated Bagging Line with Robotic Palletizing: Integrated Solution

by Columbia/Okura LLC

Automated Robot Palletizing System for Egg Producers

by Columbia/Okura LLC

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

Robotic Palletizing Systems for Diverse Packaging

byOthers