Robotic Palletizer

Advanced robotic palletizing systems that combine industrial robotics with intelligent software to provide flexible, precise, and efficient automated palletizing solutions for diverse product types and packaging requirements.

Robotic Palletizer System

Advanced robotics and intelligent software for flexible automated palletizing

Key Benefits

Advanced Robotic Architecture

Modern robotic palletizers utilize six-axis articulated robots that provide complete freedom of movement, enabling complex product handling and placement operations. These industrial-grade robots feature high payload capacities ranging from 50 to 300 kilograms, with reach capabilities extending up to 4 meters to accommodate various pallet sizes and stacking heights. Servo-driven actuators ensure precise positioning with repeatability tolerances of ±0.1mm, critical for maintaining consistent pallet quality.

The robot controller systems incorporate advanced motion planning algorithms that optimize path trajectories for maximum speed while ensuring smooth, controlled movements. Safety-rated controllers integrate multiple layers of protection, including emergency stop systems, light curtains, and collaborative safety features that enable safe human-robot interaction when required. These systems continuously monitor robot performance and environmental conditions to maintain optimal operation.

Intelligent End-of-Arm Tooling

The effectiveness of robotic palletizers largely depends on sophisticated end-of-arm tooling (EOAT) designed to handle specific product characteristics. Vacuum gripper systems feature multiple suction zones with independent control, allowing secure handling of cases, boxes, and rigid containers while accommodating slight dimensional variations. Advanced vacuum systems include leak detection and grip confirmation sensors that ensure reliable product handling.

Mechanical gripper systems provide positive gripping force for products that cannot be handled with vacuum systems, such as bags, irregular shapes, or porous materials. These grippers feature adjustable jaw configurations and force-controlled gripping that adapts to different product sizes while preventing damage. Quick-change tooling systems enable rapid EOAT swapping for multi-product operations, reducing changeover times to under 15 minutes.

Versatile Robotic Palletizer for Rigid Packaging

Vendor: Others

Vision-Guided Precision Systems

Modern robotic palletizers integrate 3D vision systems that provide real-time product recognition, positioning, and quality verification. These systems utilize laser triangulation and structured light technology to create precise three-dimensional models of incoming products, enabling accurate pickup and placement even with dimensional variations. Machine learning algorithms continuously improve recognition accuracy and adapt to new product variations.

Vision-guided positioning eliminates the need for precise product placement on infeed conveyors, as robots can automatically adjust to product location and orientation. Quality inspection capabilities identify damaged products, incorrect orientations, or missing items, automatically diverting non-conforming products to reject stations. Barcode and label reading integration ensures proper product tracking and traceability throughout the palletizing process.

Flexible Pattern Programming

Robotic palletizers excel in pattern flexibility, capable of creating complex stacking arrangements that optimize pallet stability and space utilization. Intelligent pattern generation software analyzes product dimensions, weights, and stacking characteristics to automatically create optimal pallet configurations. These systems consider factors such as center of gravity, compression strength, and interlocking patterns to ensure stable, transportable pallets.

Multi-product palletizing capabilities allow robots to handle different products simultaneously, creating mixed pallets according to order requirements. Dynamic pattern adjustment enables real-time modifications based on product availability, order changes, or quality considerations. Pattern optimization algorithms continuously analyze performance data to improve pallet configurations and reduce material waste.

MXRP (Mixed Row Palletizer): Integrated Mixed Case Palletizing

Vendor: Others

Integration and Connectivity

Advanced robotic palletizers seamlessly integrate with warehouse management systems (WMS) and enterprise resource planning (ERP) platforms to receive real-time production schedules and order information. Industrial IoT connectivity enables remote monitoring, performance analytics, and predictive maintenance capabilities. Data collection systems track key performance indicators including throughput rates, quality metrics, and equipment utilization.

Conveyor system integration ensures smooth product flow from upstream processes directly to the robotic cell. Automated pallet handling systems manage empty pallet supply and completed pallet removal, creating fully automated palletizing lines. Stretch wrapping integration enables complete pallet finishing without manual intervention, maximizing automation benefits.

Performance Optimization

Modern robotic palletizers achieve cycle times as low as 3-5 seconds per case, with throughput rates exceeding 1,200 cases per hour depending on product characteristics and pallet patterns. Adaptive speed control automatically adjusts robot velocity based on product weight, fragility, and placement requirements, optimizing both speed and quality. Predictive motion planning anticipates upcoming movements to minimize acceleration and deceleration times.

Energy efficiency optimization features include regenerative braking systems that recover energy during deceleration phases and intelligent power management that reduces consumption during idle periods. Maintenance scheduling algorithms analyze equipment performance data to predict optimal service intervals, minimizing unplanned downtime while extending equipment life.

Industry Applications and Benefits

Robotic palletizers excel in industries requiring high flexibility and product variety, including food and beverage, pharmaceuticals, consumer goods, and automotive parts distribution. The ability to handle multiple product types without mechanical changeovers makes them ideal for facilities with diverse product portfolios or frequent product changes. Gentle handling characteristics make them particularly suitable for fragile products that require careful manipulation.

Return on investment typically occurs within 18-30 months through labor cost savings, reduced product damage, and improved operational efficiency. The 24/7 operation capability and consistent performance across shifts eliminate variability associated with manual palletizing while improving workplace safety by removing workers from repetitive, physically demanding tasks. Scalability advantages allow facilities to add additional robots as production demands increase, providing flexible capacity expansion options.

🔧Related Technologies (6)

MXRP (Mixed Row Palletizer): Integrated Mixed Case Palletizing

byOthers

TiltSort-Bot: Autonomous Mobile Robot (AMR) for Sortation

by Conveyco

Industrial Robotic Palletizing System for Bulk Bags

byColumbia/Okura LLC

Automated Bagging Line with Robotic Palletizing: Integrated Solution

by Columbia/Okura LLC

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

Helix System: AI-Powered Robotic Package Sorting

byFigure AI

📚Related Packing Topics

About This Topic

📁Related Projects(6)

JD.com - Flexible Case Picking Automation with ForwardX Robotics AMRs

ForwardX Robotics

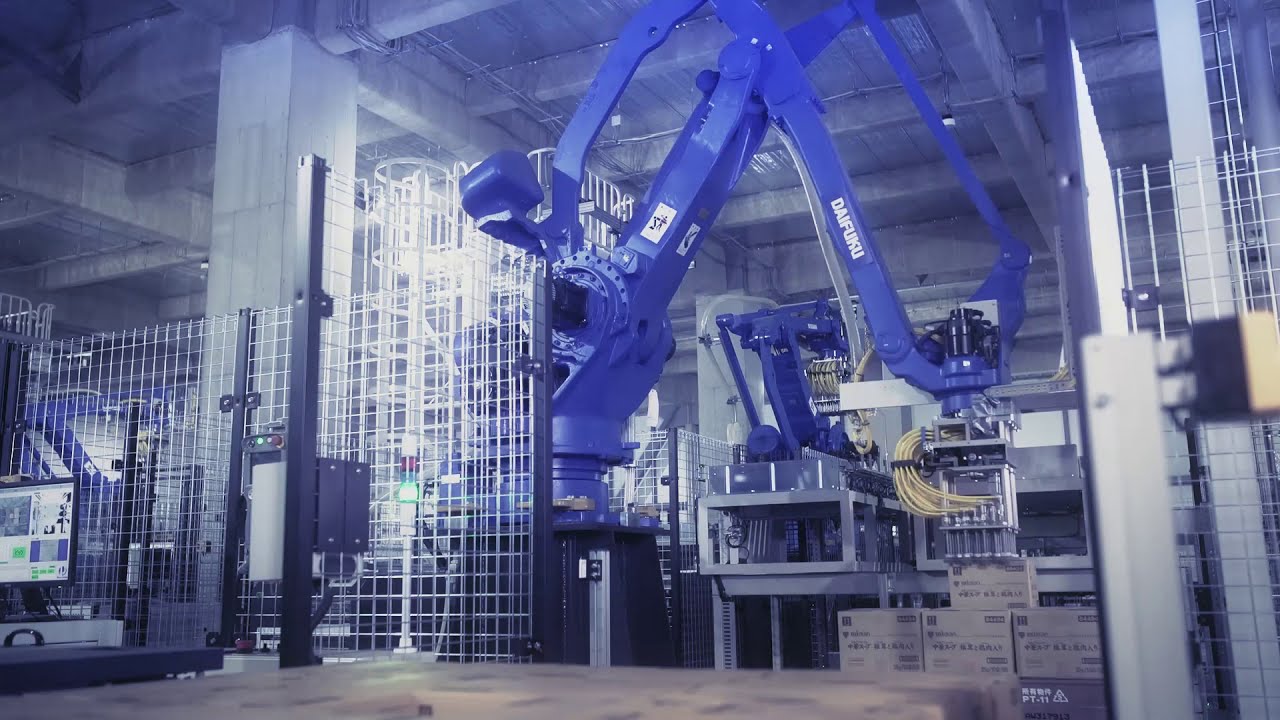

F-Line Japan Major Food Distribution Center

Daifuku

Dexterity AI & FedEx Parcel Hub Robotic Truck Loading Project

Dexterity AI

L.L.Bean - Freeport Maine Distribution Center Sortation Modernization

Beumer Group

Element Logic Ireland Warehouse Automation Solutions

Element Logic

Sengkang General Hospital Singapore Central Sterile Supply Unit

Daifuku

🏢Related Suppliers(3)

ABB Robotics

Global leader in industrial robotics and automation technology with comprehensive solutions for warehouse and logistics applications.

Universal Robots

Pioneer and global leader in collaborative robotics (cobots) with user-friendly robotic arms for industrial automation.

Exotec

Elegant Solutions to Simplify Logistic Operations