Mixed Case Palletizing

Advanced palletizing systems designed to handle diverse product configurations, optimizing pallet stability and space utilization through intelligent case arrangement and stacking algorithms.

Mixed Case Palletizing System

Advanced algorithms and robotics for optimal mixed product configurations

Key Benefits

Understanding Mixed Case Complexity

The complexity of mixed case palletizing stems from the need to optimize multiple competing objectives simultaneously. Pallet stability must be maintained while maximizing space utilization and ensuring product integrity. Modern systems employ sophisticated algorithms that analyze thousands of potential configurations in real-time, selecting arrangements that meet all stability and efficiency criteria.

Advanced mixed case palletizers utilize 3D modeling software to simulate pallet configurations before physical placement. These systems consider factors such as center of gravity, compression strength, and interlocking patterns to ensure each pallet meets transportation and storage requirements. The result is consistently stable pallets that maximize trailer utilization and minimize product damage during transit.

Intelligent Algorithm Integration

The heart of any mixed case palletizing system lies in its optimization algorithms. These sophisticated software solutions analyze incoming case dimensions, weights, and stacking rules to determine optimal placement sequences. Machine learning capabilities allow systems to continuously improve their performance by analyzing successful configurations and adjusting parameters based on real-world results.

Modern algorithms incorporate constraint-based optimization that considers multiple factors simultaneously. Weight distribution algorithms ensure proper load balancing, while compression analysis prevents damage to fragile products. Real-time adaptation capabilities allow systems to adjust configurations based on available inventory, creating the most efficient pallets possible with current product mix.

MXRP (Mixed Row Palletizer): Integrated Mixed Case Palletizing

Vendor: Others

Robotic Precision and Flexibility

Mixed case palletizing demands exceptional precision from robotic systems, as placement accuracy directly impacts pallet stability. Six-axis robotic arms provide the flexibility needed to handle diverse case orientations and placement angles. Advanced end-effector technology adapts to different case sizes and materials, ensuring secure handling throughout the palletizing process.

Vision-guided systems enhance robotic precision by providing real-time feedback on case positioning and pallet configuration. These systems can detect and correct minor placement errors, ensuring each case is positioned optimally for maximum stability. Force feedback sensors prevent damage to products while ensuring secure placement, particularly important when handling fragile or irregularly shaped items.

Pallet Pattern Optimization

Successful mixed case palletizing relies heavily on intelligent pattern generation that considers both geometric constraints and physical properties of products. Tetris-like algorithms arrange cases to minimize gaps while maintaining structural integrity. These systems analyze case dimensions to identify optimal interlocking patterns that provide maximum stability with minimum wasted space.

Layer-by-layer optimization ensures each pallet level provides a stable foundation for subsequent layers. Advanced systems consider the cumulative effect of case placement decisions, ensuring that early placement choices don't compromise overall pallet quality. Dynamic pattern adjustment allows systems to modify configurations based on real-time inventory availability and order requirements.

Robotic Layer Mixed Palletizer: High-Throughput Mixed Case Palletizing

Vendor: Others

Integration with Warehouse Systems

Mixed case palletizing systems integrate seamlessly with broader warehouse management systems to optimize overall operational efficiency. WMS integration provides real-time inventory data and order information, allowing palletizing systems to optimize configurations based on actual demand patterns. ERP connectivity ensures palletizing decisions align with broader business objectives and customer requirements.

Predictive analytics capabilities analyze historical data to anticipate optimal pallet configurations for different product mixes and seasonal patterns. This intelligence allows systems to pre-configure optimal patterns and reduce decision-making time during peak operations. Real-time reporting provides visibility into palletizing performance and identifies opportunities for continuous improvement.

Quality Control and Validation

Advanced mixed case palletizing systems incorporate comprehensive quality control mechanisms to ensure every pallet meets stability and safety standards. 3D scanning technology validates pallet configurations against predetermined criteria, identifying potential stability issues before pallets leave the system. Weight verification systems ensure proper load distribution and compliance with transportation regulations.

Automated rejection systems remove pallets that don't meet quality standards, preventing downstream issues and maintaining consistent output quality. Continuous monitoring tracks key performance indicators such as pallet stability scores, space utilization rates, and throughput metrics. This data drives ongoing optimization efforts and ensures consistent performance improvement over time.

🔧Related Technologies (6)

Robotic Layer Mixed Palletizer: High-Throughput Mixed Case Palletizing

byOthers

MXRP (Mixed Row Palletizer): Integrated Mixed Case Palletizing

byOthers

Automated Packaging on Demand System

by Conveyco

TiltSort-Bot: Autonomous Mobile Robot (AMR) for Sortation

by Conveyco

Industrial Robotic Palletizing System for Bulk Bags

byColumbia/Okura LLC

Automated Bagging Line with Robotic Palletizing: Integrated Solution

by Columbia/Okura LLC

📚Related Packing Topics

About This Topic

📁Related Projects(6)

JD.com - Flexible Case Picking Automation with ForwardX Robotics AMRs

ForwardX Robotics

Element Logic Ireland Warehouse Automation Solutions

Element Logic

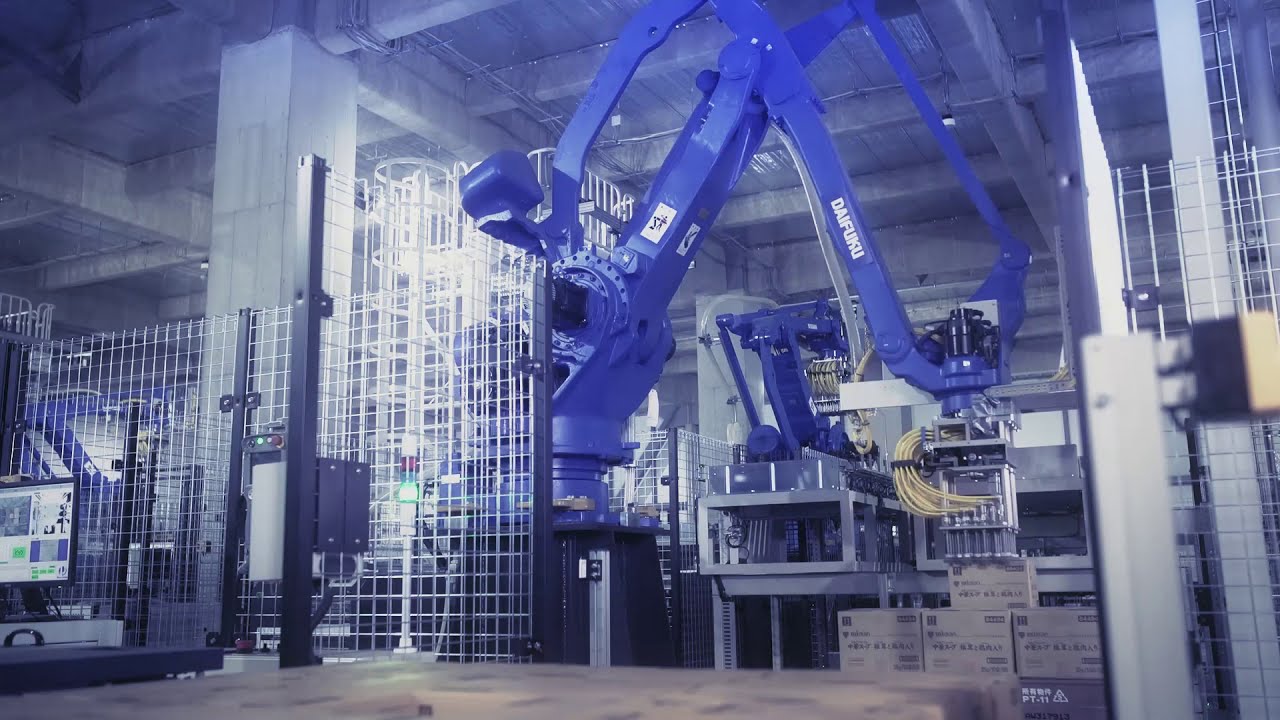

F-Line Japan Major Food Distribution Center

Daifuku

Dexterity AI & FedEx Parcel Hub Robotic Truck Loading Project

Dexterity AI

L.L.Bean - Freeport Maine Distribution Center Sortation Modernization

Beumer Group

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Daifuku

🏢Related Suppliers(3)

Addverb

Warehouse Automation that delivers value!

Bastian Solutions

A Toyota Advanced Logistics Company

BlueSword Intelligent Technology Co., Ltd.

Pioneering global warehouse automation since 1993