Quick Facts

Key Statistics

Geographic Coverage

- • A Toyota Advanced Logistics company, part of the global Toyota family since 2017

- • Employs the Toyota Production System concept of 'Jidoka' (intelligent automation that creates value)

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions, a Toyota Advanced Logistics company since 2017, leverages Toyota Production System principles like Jidoka to deliver intelligent automation and supply chain integration.

- • Integrated solution combining AutoStore cubic storage with Hytrol conveyor systems

- • ModSort (bomb-bay) sortation cells for efficient order consolidation

CNH Industrial Indianapolis Distribution Center

CNH Industrial partnered with Bastian Solutions to integrate AutoStore, conveyors, sortation cells, and WCS, optimizing their facility for same-day shipping and 24-48 hour fulfillment.

- • 7.5 miles of conveyor system handling diverse product sizes

- • Four specialized sorting areas for different product types

DICK'S Sporting Goods Conklin Distribution Center

A 650,000 square foot distribution center featuring 7.5 miles of conveyor systems, serving up to 160 stores with improved throughput and efficiency for omnichannel retail operations.

- • AutoStore system with 6 robots and 7,600 bins

- • 60% of 7,500 products stored in AutoStore

Gerrie Electric Ontario Distribution Center

Gerrie Electric implemented AutoStore with Bastian Solutions to transform their 26,000 sq ft facility, achieving 80-90 picks per person in 2 hours versus previous 7 hours.

- • Automated Storage and Retrieval System (ASRS) with crane technology for tool and die management

- • Xacta WMS integration enabling operator input via typing or scanning

Roark - Aerospace Tool & Die Automated Storage System

Roark implemented Bastian Solutions' automated storage and retrieval system for aerospace tools and dies, replacing manual pallet storage with organized ASRS for complex sheet metal fabrication.

- • Largest AutoStore installation in North America at the time, with a grid built for 305,000 bins

- • AutoStore 'Black Line' robots featuring rapid battery swaps (8-10 seconds) enabling near 24/7 operation

PUMA Indianapolis East Coast Distribution Center

PUMA, NFI/Cal Cartage, and Bastian Solutions deployed North America's largest AutoStore Black Line system, increasing capacity 10x and reducing delivery times from 8 days to 2 days.

- • AutoStore system with 53,000 SKUs storage capacity

- • Dual-mode operation for customer orders and job orders

SMC Corporation Indiana Distribution Center

A 1 million square foot distribution center featuring AutoStore goods-to-person system and pick-and-pass operation, doubling daily throughput and enabling 93% same-day shipping.

- • Opened on schedule and on budget in June 2020 despite global pandemic challenges

- • Designed with significant expansion capacity (ability to add 400,000 sq ft)

PUMA Indianapolis Pandemic-Resilient Distribution Center

PUMA's Indianapolis DC, opened on-time in June 2020 amidst the pandemic, provided critical capacity to handle surging e-commerce demand, acting as a 'beacon of hope' for future growth.

- • Over two miles of varied conveyor systems (inclined belts, spirals, gravity declines)

- • Automated document (invoice/pack list) insertion into cartons

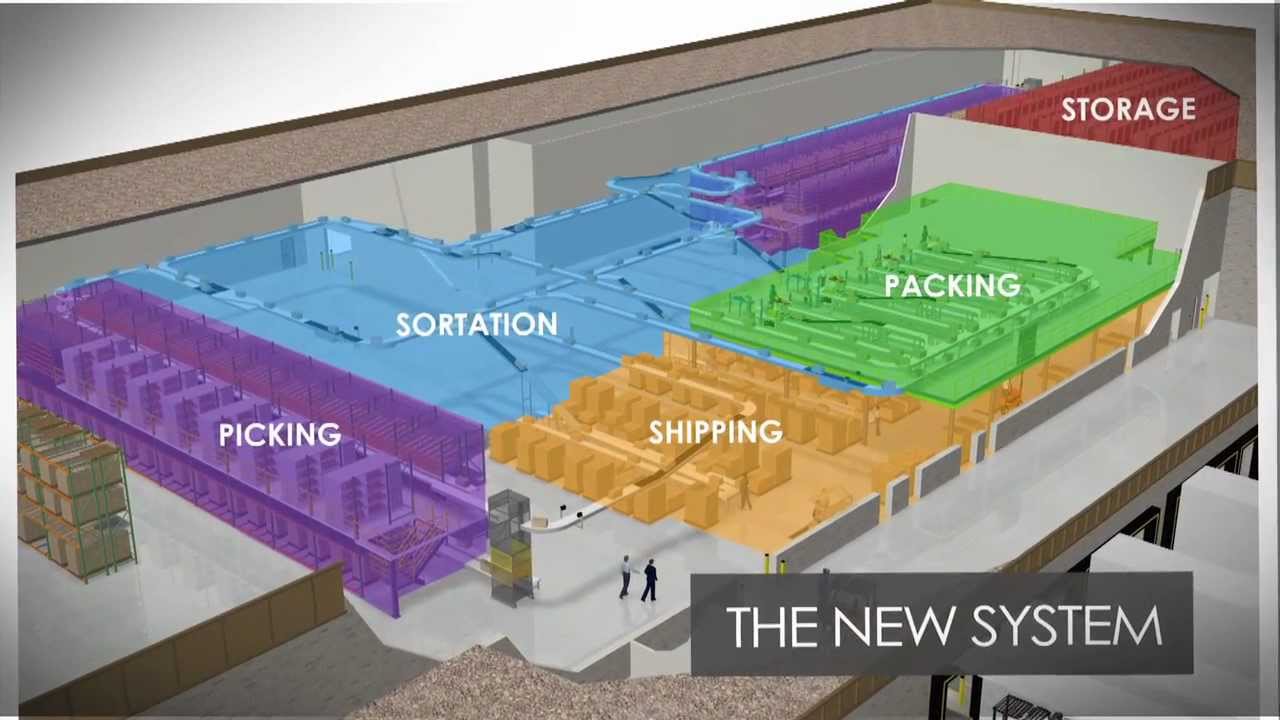

Amway Midwest Regional Service Center, Ada

Amway streamlined its Midwest fulfillment, moving to a new automated facility 50% smaller yet capable of handling over 30,000 cartons daily, achieving faster order fulfillment and reduced costs.

- • Circular, minimum-pressure style conveyor with plastic chain and UHMW pallets

- • Designed for ergonomic, stationary assembly work; operators wait at fixed points

Gleaners Food Bank Indianapolis Back Sack Assembly Line

Gleaners Food Bank collaborated with Bastian Solutions to automate its Back Sack assembly line, expanding the weekend meal program from 3,000 to 10,000 children weekly.

- • Centralized 'Administration Cube' for system control, monitoring, and statistics

- • Integrated conveyor system routing cartons through picking, packing, and manifesting

Roche Diagnostics Indianapolis Distribution Center

Roche Diagnostics transformed its distribution system with Bastian Solutions, achieving a 30% pack rate increase and 75% reduction in overtime spending.

Technology Expertise

Industry Experience

Service Capabilities

Company Overview

Bastian Solutions was founded in 1952 as E.C. Stark Co., Inc., initially supplying conventional material handling products like casters, hand trucks, and carts. In 1967, it was renamed Bastian Stark Material Handling Corporation after Bill Bastian Sr. purchased it, and in 1971, it became Bastian Material Handling Corporation. The company expanded into automated solutions and information systems in the 1980s, acquired ASAP Automation in 1997 for intralogistics software, opened its first international office in Bengaluru, India in 1998, formed Blue Arc Engineering in 2003, created a robotics division with the purchase of VanPak (renamed Bastian Robotics) in 2005, began manufacturing its own conveyor line in 2010, and was renamed Bastian Solutions in 2012. In 2015, it formed a mobile robotics division in Dallas, Texas, and in 2017, it was acquired by Toyota Automated Logistics Group (a subsidiary of Toyota Industries Corporation). In 2019, it opened an Advanced Manufacturing Facility in Westfield, Indiana.

Bastian Solutions is the 15th largest material handling system supplier in the world according to Modern Materials Handling. As part of the Toyota Automated Logistics Group, which includes Toyota L&F, Bastian Solutions, Vanderlande, and viastore, the company positions itself as a global partner for integrated logistic process automation. With over 20 U.S. offices and international offices in Brazil, Canada, India, and Mexico, Bastian Solutions has a collaborative culture promoting integrity, inclusion, and innovation, focusing on workforce engagement through automation.

The core value proposition is providing trusted supply chain integration with world-class distribution and production solutions to give clients a competitive advantage through scalable systems, innovative software, and custom automation. Key differentiators include engineering and manufacturing many of its own products, such as Bastian Solutions conveyor and Exacta Intralogistics Software, and offering solutions ranging from simple to highly automated, including mobile robots, AS/RS, AGV, goods-to-person technology, sortation, and conveyor.

Core Capabilities

Technology Solutions

Bastian Solutions offers a comprehensive portfolio of material handling technologies, including Autonomous Vehicles (AGVs & AMRs) for flexible transport, AS/RS for automated storage and retrieval, Conveyor Systems for efficient material flow, Goods-to-Person systems for ergonomic picking, Order Fulfillment technologies for high-speed processing, Palletizing solutions for automated stacking, Picking Technologies for accurate order assembly, Robotics for various automation tasks, Sortation Systems for item distribution, and Warehouse Software for control and optimization, including WMS, WES, and WCS.

The company's technology approach emphasizes combining scalable material handling systems, innovative software, and custom automation engineering to create turnkey solutions that increase productivity and reduce operational costs. Features include the use of leading technologies in equipment and information systems, with proven operational strategies tailored to client needs.

Industry Expertise

Bastian Solutions serves a broad spectrum of industries, including e-commerce with high-speed fulfillment systems, retail for omnichannel distribution, 3PL/logistics for scalable warehouses, manufacturing for production supply, food & beverage for temperature-controlled handling, parcel/courier for sortation hubs, fashion/apparel for efficient returns processing, automotive for parts handling, healthcare/pharma for compliant storage, and cold storage for perishable goods. Specific expertise includes flexible automation for workforce engagement in fashion distribution centers and improving order fulfillment speed in sporting goods retail.

Notable achievements include a 10x capacity increase and 20% faster operations for PUMA's Indianapolis distribution center with in-line packing automation, maintaining next-day delivery for Hercules Sealing Products amid growth, and enhancing accuracy at DICK'S Sporting Goods' omnichannel center.

Service Approach

Bastian Solutions' service model includes material handling systems automation and consulting, with end-to-end support from assessment of facilities and operations to selection of appropriate technologies, system design, implementation, integration, project management, installation, training, maintenance, modernization, and spare parts. The methodology involves creating personalized solutions through expert partnerships and proven processes.

The service philosophy is based on being a trusted supply chain integration partner committed to providing a competitive advantage. Geographic service coverage spans North America, Latin America, and Asia Pacific with local offices for responsive execution.

Competitive Advantages

- Global Scale and Integration: As part of Toyota Advanced Logistics, Bastian Solutions offers integrated solutions with access to group resources, enabling world-class automation across international offices in multiple countries.

- In-House Manufacturing: The company engineers and manufactures its own products like conveyors and software, ensuring quality control and customization for unique client needs.

- Innovation in Robotics: With a dedicated robotics division since 2005, Bastian Solutions provides advanced mobile robots and AGVs for demanding applications.

- Workforce Focus: Emphasis on collaborative culture and automation that prioritizes employee engagement, as seen in projects improving operations while maintaining workforce priorities.

- Proven Track Record: Ranked 15th largest material handling supplier, with over 70 years of experience delivering productivity gains and quick ROI.

Global Presence

Bastian Solutions operates primarily in North America with over 20 U.S. offices, and has international presence in Asia Pacific (India) and Latin America (Brazil, Mexico), with offices in Canada as part of North America. The office network includes regional offices in São Paulo, Brazil; Toronto and Montreal, Canada; Bengaluru, India; and San Luis Potosí and Mexico City, Mexico. This footprint supports global projects with localized expertise for design, implementation, and support.

Innovation & Technology

Bastian Solutions focuses on leading technologies in material handling equipment and information systems, with innovation through acquisitions like robotics divisions and manufacturing expansions. Emerging technologies include autonomous vehicles and goods-to-person systems for future challenges. The innovation philosophy centers on thoughtful design and proven strategies to address operational issues. Recent technological advances feature the Advanced Manufacturing Facility opened in 2019 for conveyor and automation production.

Typical Project Profile

Project Types:

- Distribution center automation with in-line packing for fashion retailers

- Facility design for manufacturing product distribution

- Omni-channel order fulfillment improvements for sporting goods retail Typical Timeline: Varies by project scope Implementation Approach: Assessment of operations, technology selection, custom engineering, installation, and ongoing support for ROI.

Why Choose Bastian Solutions

Bastian Solutions is a trusted partner for supply chain integration, offering scalable automation backed by over 70 years of experience and Toyota resources. Customers benefit from customized solutions that drive productivity and competitive advantage.

Related Technologies

- Unit Load AS/RS

- Mini-Load AS/RS

- AGV Unit Load

- Goods-to-Person Systems

- Pallet Conveyors

- Box Conveyor Systems

- Robotic Palletizer

- WMS, WES, WCS

Research Notes:

- Information gathered from: https://www.bastiansolutions.com/, https://www.bastiansolutions.com/about/, https://www.bastiansolutions.com/solutions/, https://www.bastiansolutions.com/about/media-library/case-studies/, https://www.bastiansolutions.com/solutions/technology/

- Logo URL verified: Yes

- Last updated: January 03, 2026

- Confidence level: Medium

- Any information gaps: Some pages returned 404 errors; revenue and employee count from secondary sources; industries assumed based on case studies; certifications not the specified ones