Technologies

Showing 37-48 of 50 technologies•Clear all filters

Technology database continuously updated • Latest solutions added regularly

Our Curated Technologies

50 technologies

Video Demo Available

Applications:

Autonomous part transfer between workstations or machines in manufacturing plants • Flexible material handling and kitting operations on the factory floor

Vendor: Others

Click to explore full details →

Fully automated

Video

#Simplimatic Automation#Collaborative Robot#AMR#MiR#UR5#Vision Guidance#Part Transfer#Manufacturing

MTransport

Collaborative AMR System with Vision-Guided Robotic Arm for Part Transfer

BOthersAFully automated

*Fully collaborative AMR system safe to operate alongside personnel

*Integrates Mobile Industrial Robots (MiR) MiR200 AMR, Universal Robots UR-5 6-axis arm, and RVT Collaborative Vision Factory (cVF) software

*Vision-guided pick and place with Robotic Vision Technologies (RVT) integration

TransportPickingSoftware

Watch Video

Learn More

Video Demo Available

Applications:

Warehouses requiring a single system to handle a full range of product categories (full-category) • Operations looking to automate the picking process for boxed goods

Vendor: Mushiny

Click to explore full details →

Fully automated

Video

#Mushiny#MIX#Goods-to-Person#Latent Lifting Robot#AI Picking#Mobile Racking+1

WStorage

Mushiny MIX: T-Series Latent Lifting Robot & iRES Goods-to-Person System

BMushinyAFully automated

*T-Series latent lifting robots transport movable shelves to workstations

*AI-based automatic box recognition and grabbing

*Integration with conveyor lines for delivery to picking personnel

StorageTransportPickingSortationSoftware

Watch Video

Learn More

Video Demo Available

Applications:

Autonomous transport of materials between production lines and warehouses • Moving goods across large facilities spanning indoor workshops and outdoor yards

Vendor: VisionNav Robotics

Click to explore full details →

Fully automated

Video

#AMR#AGV#Tugger#Autonomous Towing#VisionNav

RTransport

AMR/AGV Tuggers: Autonomous Towing for Trailers and Trolleys

B VisionNav RoboticsAFully automated

*Autonomous and safe towing of trailers and trolleys

*Multiple capacity models: 6,000 kg, 10,000 kg, and 20,000 kg

*CE Certified models (VNQ100 & VNQ200) for regulated environments

Transport

Watch Video

Learn More

Video Demo Available

Applications:

High-bay storage and retrieval in manufacturing and distribution centers • Narrow-aisle warehousing for space-optimized operations

Vendor: VisionNav Robotics

Click to explore full details →

Fully automated

Video

#Autonomous Forklift#AGV#AMR#VisionNav#Intralogistics Automation#5G#AI

RTransport

Autonomous Industrial Vehicles & Intralogistics Automation

BVisionNav RoboticsAFully automated

*Develops autonomous industrial vehicles based on 5G, AI, Environmental Perception, Deep Learning, and Servo Control technologies

*Offers 9 automated product series, including auto forklifts and tractor trucks

*Solutions cover full-stack intralogistics scenarios

Transport

Watch Video

Learn More

Video Demo Available

Applications:

E-commerce fulfillment centers requiring high-volume, multi-SKU piece picking • Brownfield warehouse automation projects with existing layouts

Vendor: Brightpick

Click to explore full details →

Highly automated

Video

#Autonomous Mobile Robot#Robotic Picking#AI#Goods-to-Person#Digital Twin#Brightpick+1

MTransport

Autopicker: Multi-Purpose AI-Powered Picking AMR

BBrightpick AHighly automated

*Multi-purpose AMR that seamlessly transitions between warehouse workflows

*Equipped with 'eyes' (3D vision and LiDAR), 'legs' (mobile base), 'hands' (robotic arm), and a 'brain' (Physical AI and software)

*Reliably picks a wide range of items out-of-the-box with no custom training needed

TransportPickingSoftware

Watch Video

Learn More

Video Demo Available

Applications:

Heavy pallet handling and movement for supplying AS/RS or shipping areas • Internal transport of boxes, totes, and light packages in distribution centers

Vendor: Mecalux

Click to explore full details →

Fully automated

Video

#Mecalux#AMR#Pallet Handling#Collaborative Picking#Shelf-to-Person#Intralogistics+1

MTransport

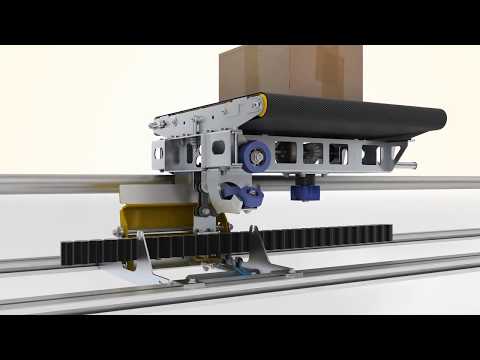

Autonomous Mobile Robot (AMR) Range: Versatile Intralogistics Automation

BMecaluxAFully automated

*Range of AMR models covering load capacities from 100 kg to 1,500 kg

*AMR 1500 Pallet Conveyor: High-capacity platform with upper conveyor for pallet movement, supplies AS/RS or shipping areas

*AMR 1500 Pallet Lifter: Transports pallets using integrated lifting platform, picks up/delivers from fixed platforms or conveyors

TransportPicking

Watch Video

Learn More

Video Demo Available

Applications:

E-commerce fulfillment with massive SKUs and fragmented orders • Operations requiring high storage density and space utilization

Vendor: Geek+

Click to explore full details →

Fully Automated

Video

#Geek+#RoboShuttle#Goods-to-Person#AMR#Warehouse Robotics#Decoupled System

MTransport

RoboShuttle Goods-to-Person System: High-Efficiency Warehouse Automation

BGeek+AFully Automated

*Decoupled parallel operation: RS robots for vertical lifting, P40 robots for horizontal transport

*Single-layer cache design on racks enables vertical and horizontal operation decoupling

*RS robot maximum lift speed of 2.7 m/s and travel speed of 1.8 m/s

TransportPickingSoftware

Watch Video

Learn More

Video Demo Available

Applications:

Retail goods distribution and fulfillment centers • Operations with daily changes in product mix and sorting requirements

Vendor: Interroll

Click to explore full details →

Fully Automated

Video

#Crossbelt Sorter#Sortation#Interroll#Material Handling#High Availability

CTransport

Crossbelt Sorter: High-Availability Multifunctional Sorting

BInterrollAFully Automated

*Multifunctional sorting for products of different shapes, sizes, and materials

*Flexible three-dimensional routing capability

*Variable arrangement of infeed and end points

TransportSortation

Watch Video

Learn More