RoboShuttle Goods-to-Person System: High-Efficiency Warehouse Automation

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

🖼️Project Gallery

📝Detailed Information

Technology Overview

In the logistics automation field, the relentless pursuit of warehouse operational efficiency has become a key business imperative. Challenges such as managing massive SKUs, processing fragmented orders quickly, and maximizing storage space utilization are critical pain points across industries. In response, Geek+ has developed the RoboShuttle solution, a goods-to-person system that achieves a leap in warehouse efficiency. This solution has been deployed globally, serving nearly 20 countries across industries like apparel, 3PL, manufacturing, and healthcare, supporting the operation of over 150 automated warehouses and processing millions of items daily. The system reportedly achieves over 20% higher overall efficiency compared to the industry average when scheduling the same number of robots in an equivalent area.

How It Works

Core Principles

The RoboShuttle is a goods-to-person picking solution. Its core operational logic is based on decoupled parallel operations, allowing different robots to specialize in their strengths. The system separates vertical and horizontal transportation tasks, enabling RS robots and P40 robots to work concurrently and independently for maximum efficiency.

Key Features & Capabilities

High-Performance Robots: The RS robot features a maximum lift speed of 2.7 m/s and a travel speed of 1.8 m/s, achieving a single-machine efficiency of up to 60 containers/hour. It supports modular end-effectors (suction cup and fork) to handle various container types. The P40 robot achieves a maximum speed of 4 m/s and a single-vehicle cycle efficiency of 30 containers/hour, utilizing advanced path planning for smooth curved trajectories.

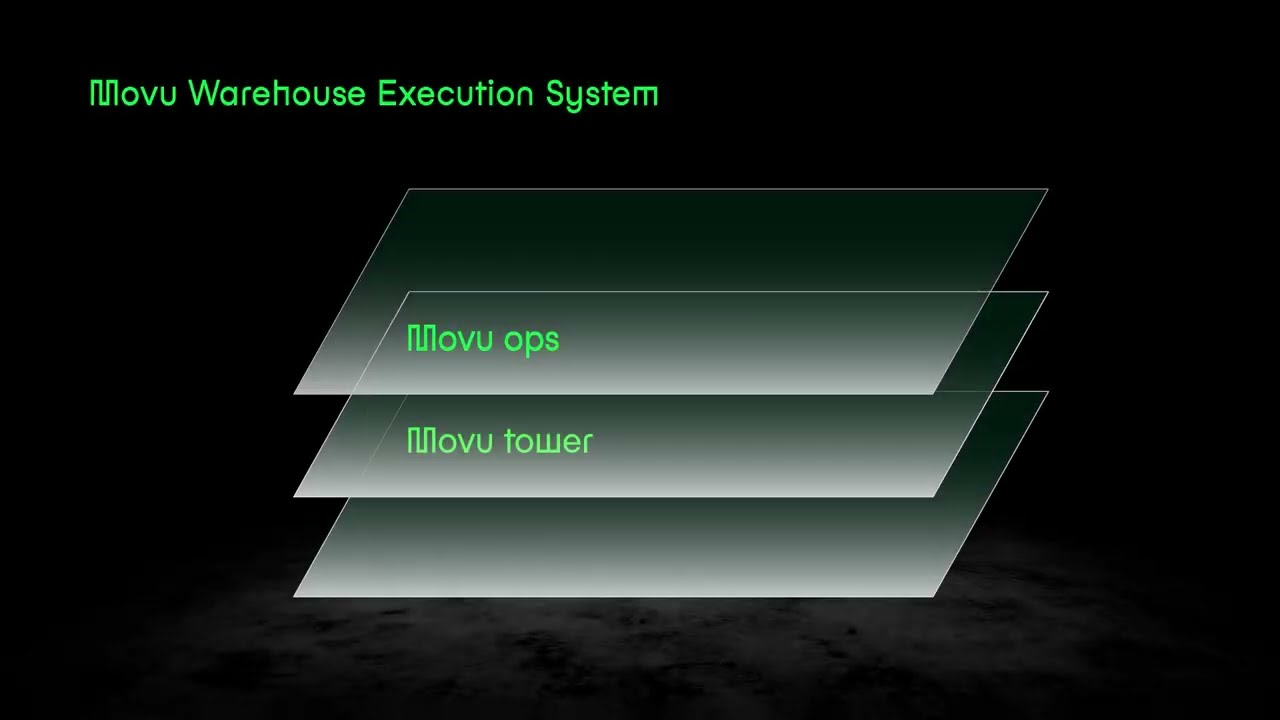

Intelligent Three-Tier Software: The system is governed by a layered software architecture. IOP provides comprehensive warehouse monitoring and data visualization. WES acts as the command center for order processing, picking, inventory counting, and replenishment, featuring high-precision pre-movement and intelligent lane balancing technologies. RMS manages large-scale, multi-robot mixed scheduling, task allocation, and path planning for up to 5000+ robots.

Advanced Optimization Algorithms: Key algorithms include a box adjustment algorithm that positions high-frequency (A-class) SKUs closer to workstations (e.g., nearer the station, inside the aisle, or in lower cache positions) for rapid throughput. RMS also employs arc motion control algorithms for optimal P40 robot movement.

Advantages & Benefits

Superior Efficiency: The decoupled design and high-performance robots contribute to an overall system efficiency that is over 20% higher than the industry average. The RS robot's cycle count is 20% above average, and the P40's efficiency is reported to be 20% higher than competitors.

Enhanced Resilience: As all tasks are performed by robots, a single-point failure (e.g., one robot malfunctioning) does not cripple the overall system's efficiency, ensuring continuous operation.

Optimal Space Utilization: The system supports storage heights up to 12 meters and container spacing as low as 20mm, increasing storage density by over 20%.

Strong Financial Returns: The gains in efficiency and storage rate drive a reduction in per-container cost by over 10%, leading to a compelling Return on Investment (ROI) and a shorter payback period.

Implementation Considerations

The solution's performance is deeply tied to its sophisticated software systems (WES, RMS) for coordination and optimization. A complete deployment involves robots, racks, workstations, and software integration. While modular deployment offers flexibility, the initial investment must be considered. The system is designed for scalability, supporting the addition of robots as business grows.

Use Cases & Applications

Ideal For

The RoboShuttle solution is ideal for e-commerce fulfillment centers dealing with a vast number of SKUs and high volumes of small, fragmented orders. It is also highly suitable for operations where maximizing storage density within a limited footprint is critical.

Performance Metrics

- Overall System Efficiency: Over 20% higher than industry average

- RS Robot Efficiency: 60 containers/hour (20% above average)

- P40 Robot Efficiency: 30 containers/hour (reported 20% higher than competitors)

- Throughput Peak (Case Study): 60,000 containers in/out per hour

- Space Utilization (Case Study): 260% improvement

- Labor Reduction (Case Study): 37% decrease in dependency

- Cost Reduction: Per-container cost reduced by over 10%

Conclusion

Geek+'s RoboShuttle goods-to-person system demonstrates a highly effective approach to warehouse automation by specializing robot functions and decoupling vertical and horizontal transport. Its combination of high-performance hardware, intelligent and layered software, and advanced optimization algorithms delivers significant gains in efficiency, storage density, and operational resilience. The solution presents a strong value proposition, particularly for e-commerce and retail businesses grappling with SKU proliferation, space constraints, and the need for faster, more adaptable order fulfillment, as evidenced by its widespread global adoption and significant client success stories.

📦Related Projects

JJCL Multi-Zone Cold Chain Automation

World's first multi-zone pallet-handling system for deep-freeze automation, automating frozen-to-chilled zone movement with zero manual transfers.

X-step Smart Warehouse

X-step implemented Geek+ Robo shuttle tote-to-person picking solution to handle international expansion and seasonal demand fluctuations in sports apparel industry.

International 3PL E-commerce Warehouse with RoboShuttle

A 3PL cross-border e-commerce warehouse utilizing Geekplus RoboShuttle, the industry's tallest mobile robot, achieving 500+ units per hour picking efficiency with maximum vertical space utilization.