Vertical Conveyor: High-Bay Material Lift Solution

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

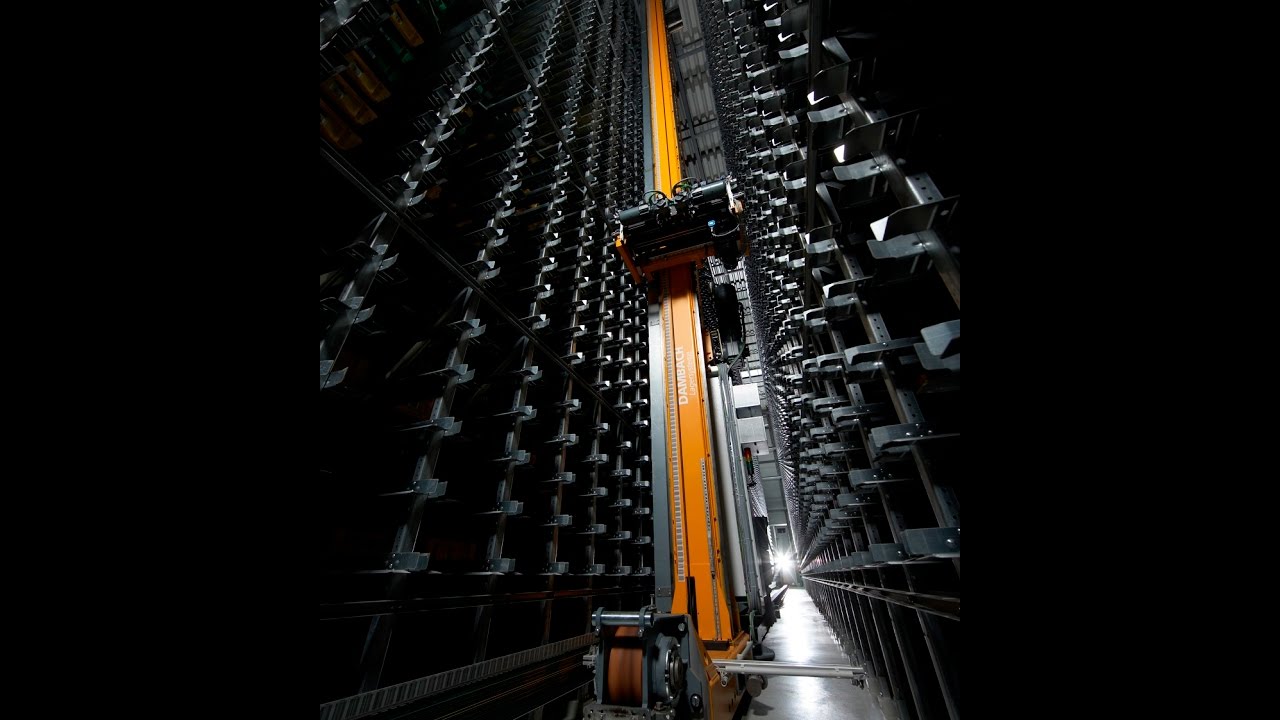

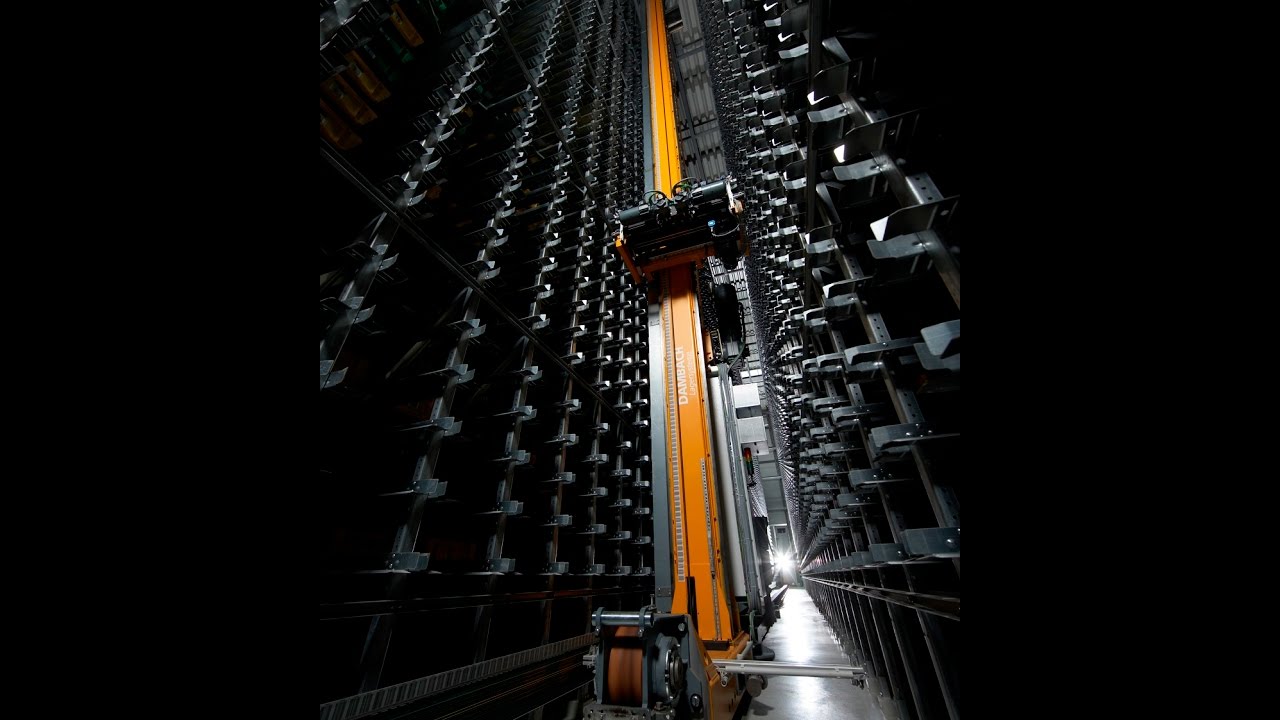

Vertical conveyors are essential components in modern automated warehouses and production facilities, serving as the critical link for moving goods between different elevations. In high-bay storage systems or multi-story buildings, they replace slow and manual freight elevators with automated, high-speed vertical transport. The DAMBACH Vertical Conveyor exemplifies this technology, designed specifically to maximize the use of vertical space—a key strategy in dense urban logistics and high-throughput distribution centers. By providing reliable, continuous, or reciprocating vertical movement, these systems integrate horizontal conveyor networks across different floors, creating a seamless three-dimensional material flow.

How It Works

Core Principles

The system operates on the principle of automated vertical reciprocating conveyance. A platform or carrier moves within a rigid, free-standing steel structure, transporting loads between predefined levels. The movement is controlled by an electric drive system (motor, gears, chains, or belts) and guided by rails. Integration with poka-yoke (error-proofing) techniques ensures safe and correct loading/unloading.

Key Features & Capabilities

The free-standing steel construction is a key feature, allowing the conveyor to be installed independently of the building structure, which optimizes warehouse space utilization and simplifies integration into existing facilities. Its impressive lifting capability up to 40 meters in height makes it suitable for very high-bay warehouses. The modular cube design is central to its value, enabling fast installation and positioning even in confined conditions, and facilitating future modifications or relocations. The consistent use of poka-yoke (error-proofing) techniques enhances operational safety and reliability by preventing loading errors and misalignments. Finally, the system's flexibility is demonstrated by its ability to support diverse load-handling devices and conveyor elements, allowing it to be tailored to handle varied material flows, from pallets to containers.

Advantages & Benefits

The primary benefit is that it lifts operational efficiency to a higher level by automating vertical transport, reducing manual handling, and increasing throughput. It enables efficient use of vertical space in high-bay warehouses, turning unused air space into productive storage or transport lanes. Its adaptable design makes it flexible and capable of handling almost any material flow requirement, providing a future-proof solution for evolving logistics needs.

Implementation Considerations

Key considerations include ensuring the facility has sufficient ceiling height and structural integrity to accommodate installations up to 40m, including necessary clearances. While modular, the system requires careful planning for integration with existing or planned horizontal conveyor systems at each interface level to ensure smooth material hand-off.

Use Cases & Applications

Ideal For

This vertical conveyor is ideal for automated storage and retrieval system (AS/RS) facilities, multi-level distribution centers, and manufacturing plants with processes spread across different floors, where reliable and fast vertical transport is a bottleneck.

Conclusion

The DAMBACH Vertical Conveyor is a robust and intelligent solution for conquering the vertical dimension in material handling. Its combination of a space-saving free-standing design, significant height capability, modular flexibility, and built-in error-proofing makes it a compelling choice for modern, high-efficiency logistics operations. By reliably automating the movement of goods between levels, it eliminates a major manual bottleneck, enhances safety, and fully leverages the cubic volume of a facility. For any operation looking to optimize vertical space and streamline inter-floor material flow, this vertical conveyor represents a strategic investment in core logistics infrastructure.

📦Related Projects

DAMBACH MINI-LOAD Automated Small Parts Storage System

The DAMBACH MINI-LOAD system is an automated storage and retrieval machine for small parts, achieving heights up to 27 meters and high throughput for container and carton storage.

LIEKEN High Bay Cold Store for Baked Goods

A high bay cold store for bread and baked goods with a capacity of 6,000 pallets at -24°C, using DAMBACH Storage and Retrieval Machines to achieve 4,296 pallet movements daily.

Dongfeng Motor R&D Center Smart Logistics Warehouse

A compact 470㎡ intelligent warehouse with 15-level high-density storage supporting 10,000+ SKUs for automotive R&D supply chain optimization.