Stingray Shuttle System: High-Performance Small Parts Handling

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

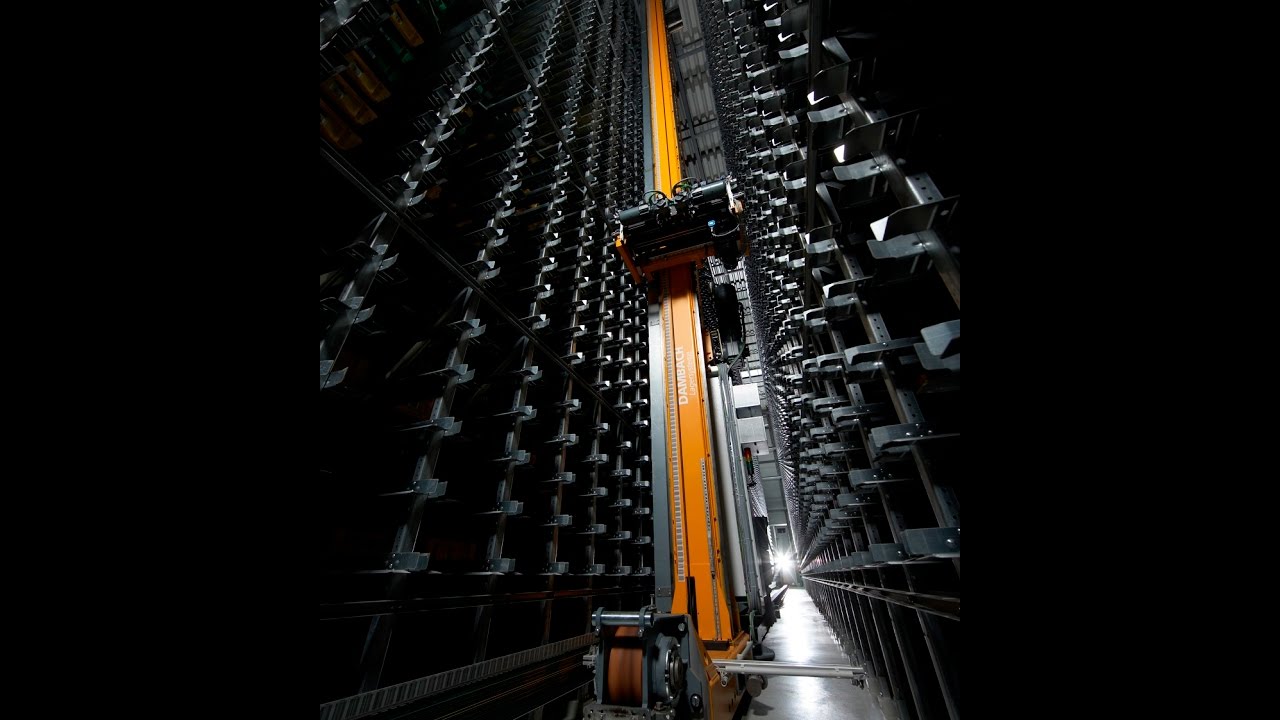

The TGW Stingray Shuttle System is a high-performance automated storage and retrieval solution engineered for the fast-paced handling of small unit loads, including individual parts, cartons, trays, and various containers. It is positioned as an ideal solution for operations where speed and reliability are paramount, particularly in supplying dynamic picking processes such as goods-to-person stations. A key strength of the system is its versatility in handling a wide range of item sizes and its ability to operate effectively in both standard warehouse environments and demanding deep-freeze conditions. By supporting storage configurations from single-deep to multi-deep, it maximizes storage density without sacrificing access speed. Furthermore, the system is designed with scalability and cost-efficiency in mind, featuring easy expansion capabilities and advanced energy recovery technology to minimize long-term operational expenses.

How It Works

Core Principles

The system operates on the principle of a multi-level, multi-deep shuttle grid. A fleet of autonomous shuttle vehicles operates on tracks within a high-density storage structure. These shuttles can store and retrieve containers from storage locations that are one, two, or more positions deep, directed by a central Warehouse Control System (WCS) to fulfill requests from picking or production areas with high dynamism.

Key Features & Capabilities

High-Performance for Dynamic Picking Supply is the system's raison d'être. It is engineered for low latency and high transaction rates, ensuring that picking stations are continuously and rapidly supplied with the correct totes, eliminating wait times and maximizing picker productivity.

Multi-Deep Storage in Normal & Deep-Freeze Environments combines density with environmental flexibility. The ability to store containers multiple deep significantly increases storage capacity. Coupled with reliable operation in temperatures as low as -30°C or below, it provides a unified solution for mixed or dedicated cold chain operations.

Scalable Architecture with Energy Recovery focuses on long-term value. The system can be expanded by simply adding more shuttles to increase throughput. The integrated energy recovery systems capture and reuse energy from shuttle braking, dramatically reducing net power consumption and contributing to a low Total Cost of Ownership (TCO).

Advantages & Benefits

The primary advantage is the combination of high speed and high storage density. The system breaks the traditional trade-off, allowing warehouses to store more inventory in a dense configuration while still accessing it rapidly to support fast order fulfillment, which is critical for e-commerce and just-in-time manufacturing.

It delivers significant reductions in operational costs and TCO. The energy recovery systems directly lower electricity bills, while the scalable design and innovative maintenance concepts reduce costs associated with expansion, downtime, and routine service.

The system provides exceptional flexibility for complex operations. Its ability to handle diverse item sizes, operate in extreme temperatures, and be scaled performance makes it a future-proof investment that can adapt to changing business needs, product lines, and growth patterns.

Implementation Considerations

As a high-performance system, it represents a substantial capital investment. The technology, including the shuttle fleet, sophisticated software, and potential cold chain adaptations, requires a clear business case centered on throughput gains, labor savings, and space optimization.

Effective operation requires advanced software integration. Managing multi-deep inventory, optimizing shuttle routes in 3D space, and integrating with upstream/downstream processes (WMS, WES, pick-to-light systems) is complex and crucial for realizing the promised performance.

Maintenance planning is essential for sustained high performance. While the system features an innovative maintenance concept, ensuring access for service and having a plan for spare parts and technical support is vital for maintaining high availability.

Use Cases & Applications

Ideal For

This system is ideal for e-commerce fulfillment centers, omnichannel retail distribution, pharmaceutical logistics, and food processing/distribution centers that require high-speed, high-density storage and retrieval of small items, especially those with mixed ambient and frozen product lines.

Performance Metrics

The content emphasizes qualitative high-performance metrics: highly dynamic supply for picking processes and optimized storage density. The significant reduction in Total Cost of Ownership (TCO) is a key financial performance indicator. The system's scalability allows its performance (throughput) to be increased by adding shuttles.

Conclusion

The TGW Stingray Shuttle System is a top-tier automation solution for businesses that cannot compromise on speed, density, or operational flexibility. It excels in environments where the swift and reliable movement of small loads is directly tied to customer satisfaction and operational efficiency, particularly in challenging conditions like deep-freeze storage. For companies aiming to lead in sectors like e-commerce, food logistics, or pharmaceuticals, the Stingray offers a powerful, scalable, and efficient technological backbone. Implementing such a system requires careful planning, a partnership-oriented approach with the integrator, and a focus on software integration. However, the investment can yield transformative gains in throughput, space utilization, and cost control, establishing a robust and dynamic core for modern, high-performance logistics operations.

📦Related Projects

Jasco - Oklahoma City Omnichannel Distribution Center Automation

Jasco launched a highly automated omnichannel distribution center in Oklahoma City (April 2022) with TGW and Burns & McDonald, handling 20,000+ daily pallet/parcel orders to boost productivity and reduce employee physical strain.

Bruges Belgium FlashPick® Automated Warehouse System

TGW implemented a high-performance FlashPick® system in Bruges, Belgium, addressing double-digit annual growth, labor scarcity, and space constraints with modular, high-density automation.

HiperDino - Telde Canary Islands Automated Warehouse with TGW Rovolution

Canary Islands-based HiperDino implemented TGW's FlashPick® and AI-powered Rovolution picking robot at its 50,000 m² Telde warehouse, handling 7,000 daily pallets and 5,000-10,000 tobacco cartons/day for 235 stores.