CycloneCarrier: Dynamic Shuttle System for Small Loads

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

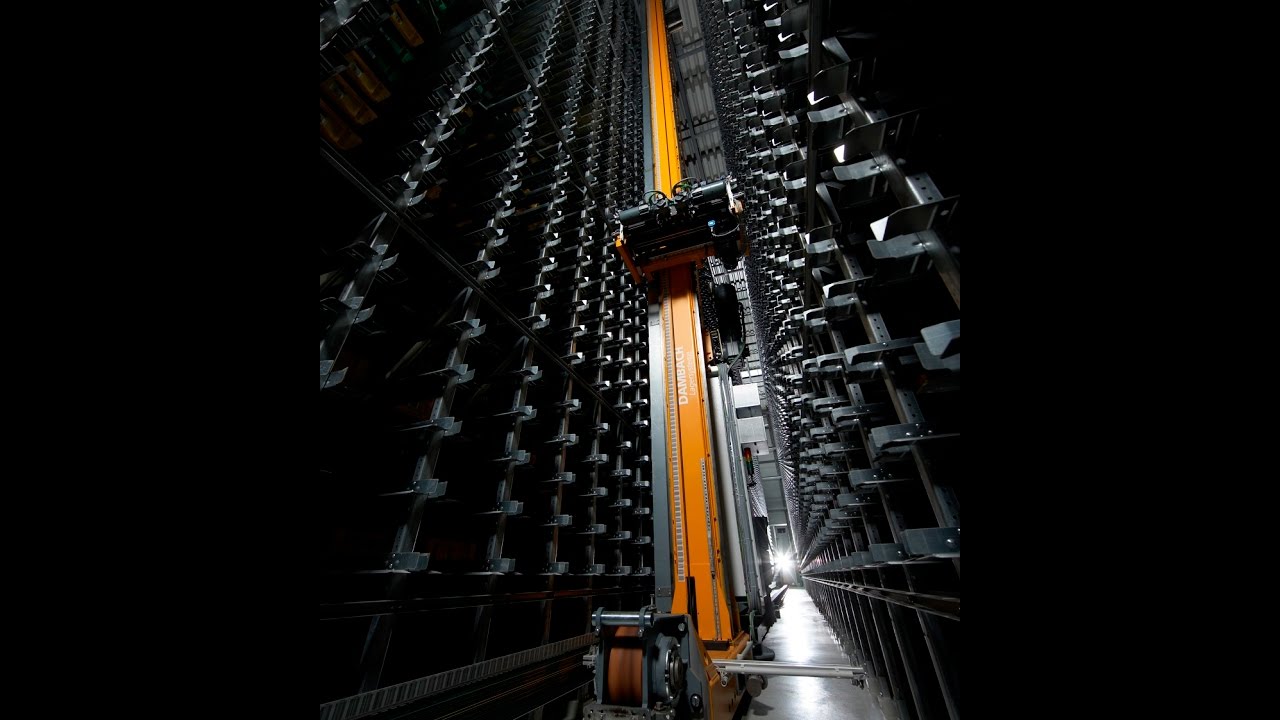

The CycloneCarrier by Swisslog is a dynamic, automated shuttle system specifically engineered for the high-speed storage and retrieval of small unit loads, such as plastic totes, trays, and cartons. It is designed to meet the extreme demands of modern logistics sectors where speed, reliability, and density are non-negotiable. This system excels in environments like e-commerce fulfillment, pharmaceutical distribution, and temperature-controlled food logistics, where order cycles are short and system uptime is critical. A key design principle is maximizing storage density without compromising throughput. By enabling storage depths of two to four loads deep and supporting massive system dimensions—up to 150 meters in length and 25 meters in height—the CycloneCarrier dramatically reduces the number of aisles required, transforming the storage area into an ultra-dense, high-speed automated buffer.

How It Works

Core Principles

The system operates on the principle of multi-level, multi-deep shuttle-based automation. A fleet of autonomous shuttle vehicles operates on tracks within a multi-level storage grid. Each shuttle can travel horizontally on its assigned level and access storage locations that are two to four positions deep, retrieving or storing containers as directed by a central warehouse control system (WCS).

Key Features & Capabilities

Double to Quadruple Deep Storage is a core density feature. Unlike single-deep systems, this allows multiple containers of the same SKU to be stored in a single lane, maximizing space utilization and reducing the number of shuttle trips for replenishment of fast-moving items.

Massive System Scale (150m long, 25m high) enables exceptional storage capacity within a single, continuous footprint. This large scale minimizes the number of aisles and transfer points, streamlining material flow and allowing a single shuttle fleet to service a vast storage volume efficiently.

Dynamic, High-Throughput Design is built into its architecture. The system is engineered for applications where excellent availability and fast transaction times are essential. The use of a coordinated shuttle fleet and efficient vertical lifts ensures rapid response to storage and retrieval requests.

Advantages & Benefits

The primary advantage is extremely high storage density combined with high throughput. The system solves the traditional trade-off between density and speed, allowing warehouses to store a massive amount of inventory in a compact area while still accessing it quickly to fulfill orders.

It delivers superior system availability and reliability, which is crucial for 24/7 operations in e-commerce, pharma, and food distribution. The redundant design (multiple shuttles) and robust construction ensure continuous operation even if individual components require maintenance.

The system offers future-proof scalability and flexibility. Its modular design and large potential scale mean it can be expanded as business grows. Its suitability for ambient, chilled, and frozen environments also provides flexibility for companies with complex supply chains.

Implementation Considerations

Implementing a system of this scale (up to 25m high) requires a facility with substantial ceiling height and robust structural support. This often limits it to new construction or specially retrofitted buildings.

The high-performance design comes with a corresponding capital investment. The cost of the shuttle fleet, high-bay racking, lifts, and advanced software is significant, necessitating a clear business case based on throughput gains, labor savings, and space efficiency.

Optimal performance depends on sophisticated software and system integration. The WCS must intelligently manage inventory placement (slotting), shuttle traffic, and order sequencing to fully leverage the system's speed and density capabilities.

Use Cases & Applications

Ideal For

This system is ideal for large-scale e-commerce retailers, third-party logistics (3PL) providers, pharmaceutical distributors, and grocery/food service companies that require automated, high-speed handling of a vast number of totes or cartons in a dense storage configuration.

Performance Metrics

The content emphasizes high throughput and excellent availability as key performance indicators. The system's physical scale (150m long, 25m high) and storage depth (double to quadruple deep) are key structural metrics that directly enable its high-density, high-performance characteristics.

Conclusion

The Swisslog CycloneCarrier represents a top-tier solution for automated small-parts storage where density and speed are paramount. It is a system designed for large, sophisticated operations that need to manage immense SKU counts with rapid transaction times, particularly in sectors with high service-level expectations. For companies facing explosive growth in e-commerce, stringent requirements in pharma, or the complexities of cold chain logistics, the CycloneCarrier offers a powerful, scalable, and reliable automation backbone. Implementation is a major undertaking that requires careful planning around facility design, system sizing, and process integration, but the payoff is a transformative boost in storage capacity, operational speed, and process reliability that can provide a sustained competitive advantage.

📦Related Projects

Spar Waalwijk Distribution Center

Spar's mechanized distribution solution handling slow and medium moving items with Swisslog automation, supporting rapid retail expansion of 3 new stores weekly.

Medline Industries Healthcare Distribution Center

First US deployment of Swisslog AutoStore system achieving 1,000 picks per hour per person, five times faster than traditional manual picking for healthcare supply distribution.

Agile Cold Storage Distribution Center

Third-party cold storage facility tripling pallet capacity to 48,000 in 110,000 sq ft using Swisslog ASRS with SynQ software, serving food manufacturers and global export markets.