SSI SCHAEFER Miniload Crane (SMC): Automated Storage for Small Loads

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

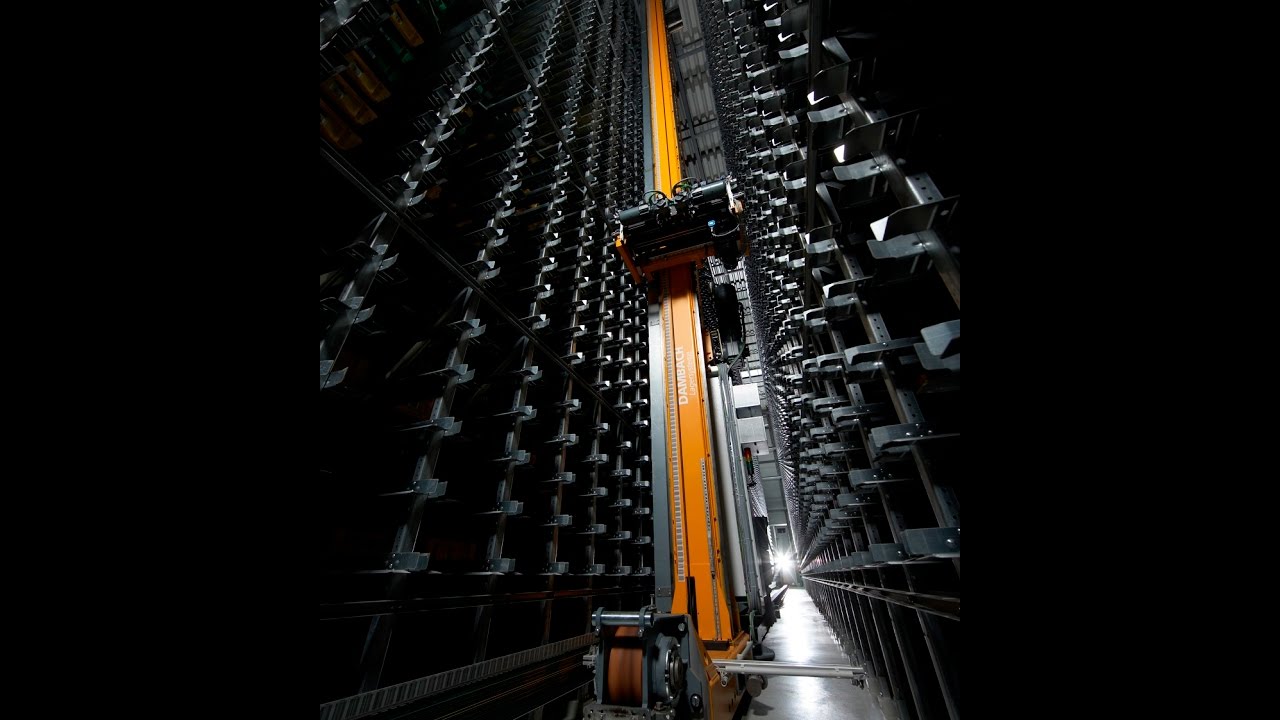

The SSI SCHAEFER Miniload Crane (SMC) represents a comprehensive automated storage and retrieval system (ASRS) solution specifically engineered for handling small load carriers such as totes, cartons, and trays. It addresses the critical need for maximizing storage capacity in modern logistics facilities where floor space is at a premium. By utilizing the full available height of a building, the SMC system dramatically increases storage density while occupying a minimal ground footprint. Its design philosophy centers on flexibility, with a range of customizable load handling devices that make it suitable for storing a vast array of item shapes, sizes, and surfaces, effectively removing traditional restrictions associated with automated storage.

How It Works

Core Principles

The system operates on the principle of an automated storage/retrieval machine (SRM or crane) operating within a high-bay racking structure. The crane travels vertically and horizontally along the rack face to automatically store and retrieve load carriers from specific locations.

Key Features & Capabilities

Vertical Space Maximization is the core capability, allowing the system to build upwards, often to great heights, to store a massive number of carriers in a small area. Minimal Floor Space Usage ensures that valuable ground area is conserved for other operational activities. The Variety of Load Handling Devices is a critical feature, enabling the system to adapt to different carrier types and delicate or irregularly shaped items without damage. This versatility provides Almost Unrestricted Storage for a wide spectrum of products.

Advantages & Benefits

The primary advantage is achieving exceptional storage density, which can lead to significant savings on warehouse real estate or allow for more inventory within an existing facility. The system dramatically improves inventory management accuracy and speed through automation. It supports high-throughput operations suitable for both storage and dynamic buffering. The flexibility in handling devices future-proofs the investment, allowing it to adapt to changing product lines and packaging formats.

Implementation Considerations

Implementing a Miniload ASRS requires a facility with sufficient ceiling height to justify the vertical investment. The system must be integrated with inbound/outbound conveyors or other transport systems, and with warehouse management software (WMS) for optimal control. The initial capital expenditure is significant, and the ROI is typically realized through long-term savings in space, labor, and improved operational efficiency.

Use Cases & Applications

Ideal For

This system is ideal for operations with high-SKU counts of small to medium-sized items where space optimization, high throughput, and inventory accuracy are critical.

Conclusion

The SSI SCHAEFER Miniload Crane (SMC) is a robust and highly adaptable ASRS solution that effectively solves the challenge of storing high volumes of small items in a limited space. By going vertical and offering configurable handling options, it delivers maximum density, operational efficiency, and future flexibility. For distribution centers, manufacturing plants, and logistics providers looking to automate their small-parts storage and retrieval processes, the SMC system represents a strategic investment that can yield substantial gains in space utilization, productivity, and process control.

📦Related Projects

MPE Plastics Turin Automotive Warehouse

MPE implemented SSI Schaefer's mobile racking and AGV solution to maximize storage capacity and meet automotive industry reliability requirements.

ASKO Oslofjord Automated Distribution Center

ASKO proactively addressed capacity constraints with SSI Schaefer's automated DC solution, achieving 80-90% process automation with strong sustainability focus.

Imbach Logistik - Luzern Logistics Center Automation

Swiss company Imbach Logistik built the Luzern Logistics Center with SSI Schaefer's automation solution, offering 130,000 container slots, 6,000+ pallet positions, and 116 pallets/hour picking rate to grow efficiently on limited space.