Miniload AS/RS: Energy-Efficient Box Stacker

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

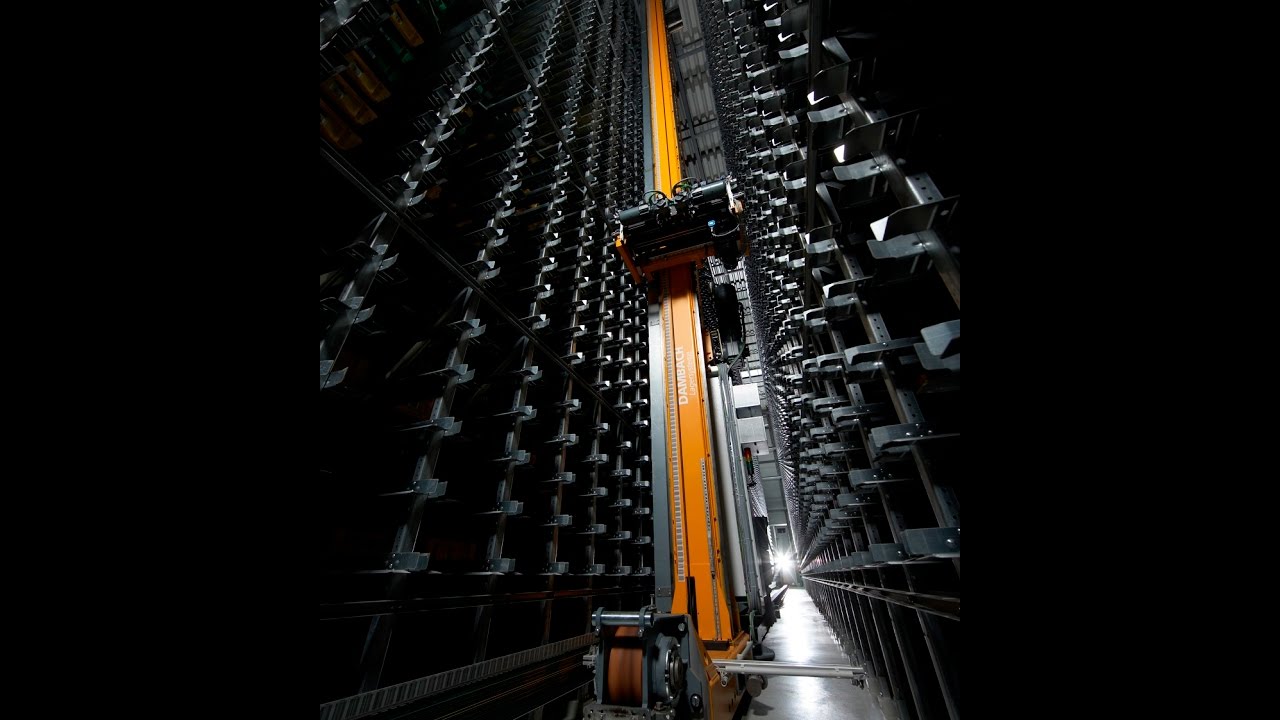

The Eotek (formerly Eoslift) Miniload AS/RS represents a focused approach to automating box-type storage, emphasizing efficiency in both space and energy. This system is engineered for automatic warehouses that handle standardized boxes or totes, aiming to maximize the utilization of the available cubic volume. Its design philosophy centers on intelligent innovation applied to core components: the rail system and the drive mechanism. By incorporating an innovative rail concept and a classic, integrated Omega power module, the system is built for smooth operation and energy recovery. A key differentiator is its light-load design philosophy, which reduces the moving mass of the stacker crane. This reduction directly contributes to higher operational speeds and lower energy consumption, making it a solution focused on performance and sustainability for modern logistics facilities.

How It Works

Core Principles

The system operates on the standard mini-load ASRS principle of an automated stacker crane storing and retrieving boxes within a high-density racking structure. Its distinctive core principles are lightweight construction and regenerative energy management. The lightweight design minimizes inertia, allowing for faster acceleration and deceleration. The integrated drive system recovers kinetic energy during braking, converting it back into usable electricity, which is fed back into the system.

Key Features & Capabilities

Innovative Rail Concept and Omega Power Module form the mechanical and electrical heart of the system. While details are not specified, this combination is presented as enabling smoother travel, precise positioning, and the foundational capability for efficient energy recovery.

Braking Energy Recovery System is a standout feature for operational sustainability. This system captures energy that is typically wasted as heat during braking and converts it back into electrical energy, significantly improving the overall energy utilization efficiency of the warehouse automation system.

Light-Load Design for Enhanced Performance is a fundamental engineering choice. By reducing the weight of the stacker crane itself (through material selection and structural design), the system requires less energy to move and can achieve higher speeds and accelerations, directly boosting throughput and reducing cycle times.

Advantages & Benefits

The primary advantage is superior energy efficiency and lower operating costs. The combination of lightweight design and regenerative braking drastically reduces power consumption per storage/retrieval cycle, leading to tangible savings on electricity and a smaller carbon footprint.

It delivers increased throughput and faster cycle times. The lightweight construction allows for quicker starts and stops, enabling the crane to complete more transactions per hour compared to heavier, conventional stacker cranes, thus improving overall warehouse responsiveness.

The system maximizes valuable storage space. As a mini-load ASRS designed for boxes, it inherently uses high-bay, narrow-aisle configurations to make the most of the facility's cubic volume, allowing for greater inventory capacity within the same building footprint.

Implementation Considerations

The innovative rail concept and integrated power module may represent proprietary technology. This could implications for long-term maintenance, parts availability, and required technician expertise compared to systems using more standard components.

The light-load design implies a specific performance envelope. Potential users must ensure the system's weight capacity and dimensional specifications align with their specific box sizes, weights, and required throughput to avoid under-sizing.

As with any high-performance ASRS, the control system integration is crucial. The system's intelligence and efficiency can only be fully leveraged if it is seamlessly integrated with the broader Warehouse Management (WMS) and Execution (WES) systems.

Use Cases & Applications

Ideal For

This system is ideal for distribution centers, manufacturing warehouses, or archival facilities that store a high volume of uniform boxes or totes and are keen on implementing green logistics initiatives. It is suited for operations looking to balance high density with energy-conscious automation.

Performance Metrics

The content emphasizes qualitative performance gains: maximum energy utilization efficiency, faster speed, and lower energy consumption. Key inferred metrics include a high percentage of energy recovery during braking, reduced kilowatt-hour usage per pallet move, and improved cycles per hour due to the lightweight, high-acceleration design.

Conclusion

The Eotek Miniload AS/RS system presents a compelling option for businesses seeking an automated box storage solution that prioritizes energy efficiency and speed. Its focus on lightweight engineering and regenerative energy capture addresses two critical operational costs: energy consumption and throughput capacity. For facilities with consistent box-handling needs and a desire to implement sustainable warehouse practices, this system offers a technologically advanced path. Prospective users should engage with the supplier to obtain detailed specifications on energy recovery rates, speed profiles, and load capacities to ensure a perfect fit for their operational requirements and sustainability goals.