Our Curated Projects

21 projects

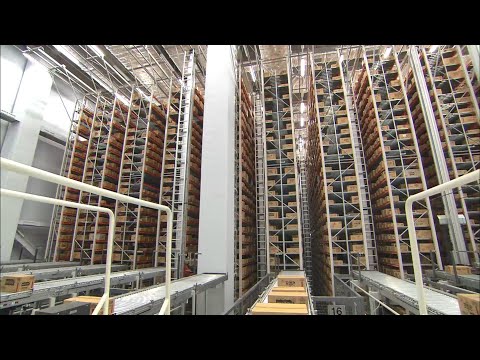

DAMBACH MINI-LOAD Automated Small Parts Storage System

The DAMBACH MINI-LOAD system is an automated storage and retrieval machine for small parts, achieving heights up to 27 meters and high throughput for container and carton storage.

Körber ErgoUnload Parcel Unloading System

Körber's ErgoUnload system provides ergonomic trailer unloading solution that increases throughput to 3,000 parcels per hour while reducing physical effort by 90%.

Sengkang General Hospital Singapore Central Sterile Supply Unit

A Singapore hospital transformed its surgical instrument logistics with a mini load AS/RS, vertical carousels, and robotic picking, integrated with barcode tracking and WMS/WCS to optimize the sterile supply flow.

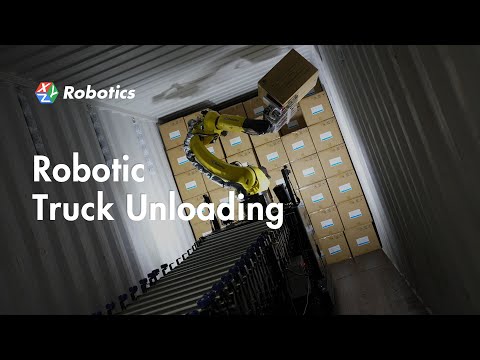

XYZ Robotics - Japanese 3PL Warehouse Robotic Truck & Container Unloading Project

XYZ Robotics deploys RockyOne Mobile Manipulation Robot to automate truck and container unloading for a Japanese 3PL warehouse, handling 15-kg cartons in 40-ft containers within 2 hours.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Lao Gan Ma Guiyang Guizhou Production Warehouse

The iconic Chinese chili sauce brand automated its production logistics with a large-scale Unit Load AS/RS, palletizing robots, and STVs to connect 7 lines across 6 factories, achieving high inbound/outbound throughput.

Deli Group Ninghai Intelligent Logistics Center

China's leading office supplies manufacturer built a 110,000 sq m intelligent logistics center with a multi-system AS/RS complex, AMRs, and picking robots to process 200,000 cases daily and store 130,000 pallets.

F-Line Japan Major Food Distribution Center

A high-tech food distribution center in Japan automated its entire logistics flow with multiple AS/RS, pallet shuttles, and robotic palletizing to handle 90,000 cases daily from 1.15 million in storage.

Snack Brands Australia Sydney Distribution Center

Snack Brands consolidated two warehouses into a 30,255 sqm facility with Daifuku's high-bay AS/RS, achieving fully automated distribution for iconic snack brands.

Lidl Køge Distribution Center

Lidl's distribution center in Køge, Denmark utilizes Vanderlande's automated case picking solution with ADAPTO shuttle-based AS/RS to outperform traditional order fulfillment methods.

NEXT Doncaster Furniture Distribution Center

NEXT implemented Körber's automated pallet handling solution with RGVs and ASRS across two warehouses for fast furniture and goods movement with 77,000 pallet locations.

Agile Cold Storage Distribution Center

Third-party cold storage facility tripling pallet capacity to 48,000 in 110,000 sq ft using Swisslog ASRS with SynQ software, serving food manufacturers and global export markets.

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions, a Toyota Advanced Logistics company since 2017, leverages Toyota Production System principles like Jidoka to deliver intelligent automation and supply chain integration.

BORT Logistics Center

Viastore implemented an automated logistics center for medical technology manufacturer BORT, featuring bulk storage, picking modules, and comprehensive conveyor systems.