Our Curated Projects

51 projects

LIEKEN High Bay Cold Store for Baked Goods

A high bay cold store for bread and baked goods with a capacity of 6,000 pallets at -24°C, using DAMBACH Storage and Retrieval Machines to achieve 4,296 pallet movements daily.

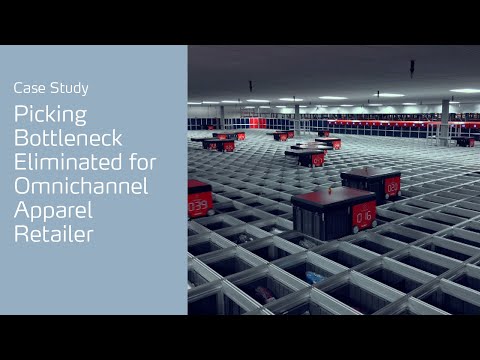

Cutter & Buck Seattle Apparel Fulfillment Center

Cutter & Buck deployed an AutoStore system with 34,000 bins and 54 robots, implemented by Kardex, to streamline apparel fulfillment, reduce storage footprint by 50%, and achieve order turnaround in under 10 minutes.

Fashion Retail Automated Hanging Garment Warehouse

Automated storage and handling system for 8 million hanging garments featuring grid conveyor transport, dynamic buffering, and multi-stage matrix sortation.

BevChain Australia Distribution Center

Australia's first high-density PowerStore system increasing pallet storage capacity by 60% in the same footprint, handling over 30,000 pallet locations across five levels.

PUMA - Geiselwind Multi-Channel Automated Distribution Center

PUMA’s highly-automated distribution center in Geiselwind, Germany, uses TGW’s FlashPick® system (700,000 storage locations) to dispatch 74 million items/year with 10-minute order-to-issue time, serving retail and wholesale channels.

Peterbilt - ASRS Aisle 4 Retrofit Project

Peterbilt retrofitted ASRS Aisle 4 to increase storage capacity for large integral cab sleeper units, completed 6 weeks early with no production disruptions by Daifuku.

Dongfeng Motor R&D Center Smart Logistics Warehouse

A compact 470㎡ intelligent warehouse with 15-level high-density storage supporting 10,000+ SKUs for automotive R&D supply chain optimization.

Jasco - Oklahoma City Omnichannel Distribution Center Automation

Jasco launched a highly automated omnichannel distribution center in Oklahoma City (April 2022) with TGW and Burns & McDonald, handling 20,000+ daily pallet/parcel orders to boost productivity and reduce employee physical strain.