Our Curated Projects

50 projects

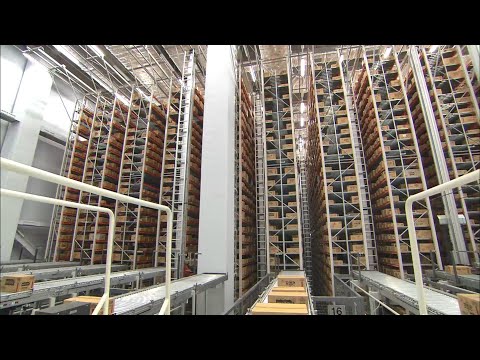

Snack Brands Australia Sydney Distribution Center

Snack Brands consolidated two warehouses into a 30,255 sqm facility with Daifuku's high-bay AS/RS, achieving fully automated distribution for iconic snack brands.

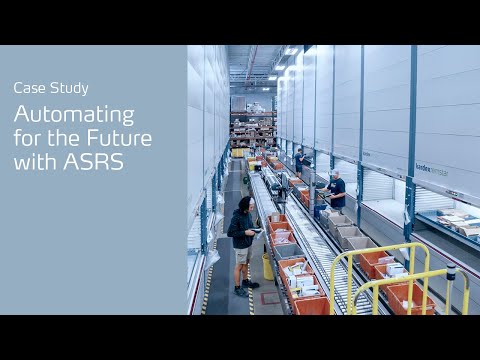

SHAKE-HAND - Belgian Standard Elements Automated Storage

SHAKE-HAND implemented Kardex Miniload-in-a-Box systems including extended VBM units to replace manual storage, doubling capacity and reducing picking errors for machine builder distribution.

Ariat Wholesale Footwear & Apparel Order Fulfillment Center

A wholesale footwear and apparel brand automated order consolidation with the EuroSort Twin Push Tray Sorter, integrating Exotec and Geek+ robotic picking to process up to 16,000 items per hour.

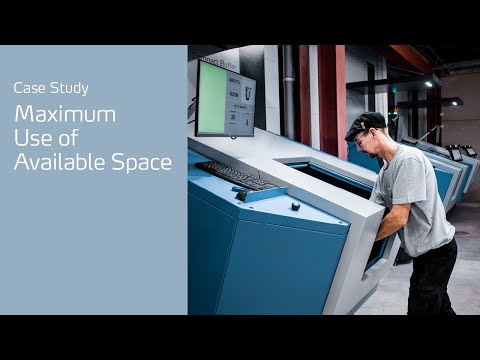

Van Meter - Cedar Rapids Electrical Distribution Warehouse Automation

Van Meter implemented 18 Kardex vertical lift modules and conveyor systems to automate electrical parts distribution, achieving 99.99% accuracy and supporting business growth goals.

Lotte Korea Confectionery Centralized Distribution Center

A leading Korean confectionery producer consolidated its logistics by building a massive automated DC next to its factory, featuring ambient & freezer AS/RS and a Mini Load system to handle 25,000 cases daily.

CNH Industrial Indianapolis Distribution Center

CNH Industrial partnered with Bastian Solutions to integrate AutoStore, conveyors, sortation cells, and WCS, optimizing their facility for same-day shipping and 24-48 hour fulfillment.

Balluff Inc. Sensor Solutions Automated Warehouse

Balluff Inc. achieved a 177% throughput increase with an AutoStore system implemented by Kardex, featuring an innovative cross-building design installed in just 6 months.

Bruges Belgium FlashPick® Automated Warehouse System

TGW implemented a high-performance FlashPick® system in Bruges, Belgium, addressing double-digit annual growth, labor scarcity, and space constraints with modular, high-density automation.

DPD Warszawa - Poland Logistics Center Parcel Sorting Automation

DPD Warszawa implemented BEUMER Group's BG Line Sorter at its Poland logistics center, delivering 1,500-10,000 items/hour throughput with active slat-belt technology for diverse parcel handling.

CEWE Stiftung - Oldenburg Production & Distribution Center Automation

psb intralogistics implemented a dynamic pouch sorter and lying goods conveyor system at CEWE Stiftung's Oldenburg facility, handling 2,500 order lines/hour and 4,000 single orders/hour to optimize multi-item order consolidation and shipping efficiency.

Rohlik.cz Prague Fulfillment Center

Rohlik Group automated its Prague e-grocery fulfillment center with Brightpick Dispatcher robots for intelligent order consolidation and dispatch, smoothing daily picking volumes.

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

A high-bay automated warehouse system using shuttle operation in storage channels to achieve maximum pallet capacity and high throughput, specifically implemented for frozen goods storage.

Vinamilk Saigon Dairy Factory Cold Storage Warehouse

Vietnam's leading dairy producer implemented a cold-environment Automated Storage and Retrieval System (AS/RS) that quadrupled storage capacity while enhancing efficiency and quality control in its logistics operations.

Netrush Kentucky E-commerce Fulfillment Warehouse

A US 3PL automated order picking and replenishment with Brightpick Retriever robots, a Goods-to-Person solution, to handle 20,000 daily orders with peaks 4-5x higher.