CEWE Stiftung - Oldenburg Production & Distribution Center Automation

⭐Key Features

- •Dynamic pouch sorter with 8 buffer carousels and 3-stage matrix sorting for multi-item order consolidation

- •Handles up to 2,500 order lines/hour and 4,000 single orders/hour via integrated lying goods conveyor technology

- •8 loading stations for pouch filling and 10 packing stations for order consolidation

- •Pre- and Post-buffer modules enhancing sorting performance and optimal loading of unpacking/packing stations

- •Space-efficient 2-level design utilizing overhead space in an existing warehouse without expanding the footprint

- •Unified material flow for single/multi-item orders and diverse recipients (end customers, retailers, sister companies)

📊Results & Benefits

- ✓Automated consolidation of multi-item orders from disjointed production areas into a single package per customer

- ✓Achieved sorting capacity of 2,500 order lines/hour and direct routing of 4,000 single orders/hour

- ✓Optimized space utilization in an existing warehouse through vertical 2-level system design

- ✓Streamlined shipping process for 21 European countries, 20,000 retail partners, and internal sister companies

- ✓Increased operational efficiency and order processing quality while enabling business growth

🎯Challenges & Solutions

Consolidating time-staggered multi-item orders from disjointed production areas and sister companies

Implemented dynamic pouch buffer and 3-stage matrix sorter to batch and automate order line consolidation

Maximizing space utilization without expanding the existing warehouse footprint

Designed 2-level overhead conveyor system with optimal vertical space usage, fitting within the existing building height

Unifying material flow for diverse order types (single/multi-item) and recipients (end customers, retailers, internal)

Integrated pouch sorter with lying goods conveyor technology for consistent, efficient workflow across all order/recipient types

📝Project Overview

Project Overview

CEWE Stiftung’s headquarters in Oldenburg, Germany—its largest production site—handles both in-house manufacturing and receives products from 14 sister companies. The facility distributes to end customers, over 20,000 retail partners across 21 European countries, and supplies other company locations. To support further growth and enhance efficiency and quality in shipping operations, the company identified a critical need to automate and optimize its shipping processes, particularly for multi-item orders that arrived staggered from disjointed production areas and sister companies.

The core challenge lay in consolidating time-staggered items from various sources into cohesive orders, a process with significant room for improvement. CEWE sought a solution that could buffer, sort, and consolidate orders automatically while integrating seamlessly with existing operations. Additionally, the solution needed to fit within the existing warehouse space without requiring expansion, as the project was constrained to the current shipping area in an existing building with limited height.

psb intralogistics was selected to deliver a comprehensive intralogistics solution centered on a dynamic pouch sorter, complemented by lying goods conveyor technology. This integrated system aimed to unify material flow across all order types and recipient categories, ensuring efficient processing regardless of order complexity or destination.

Technical Solution

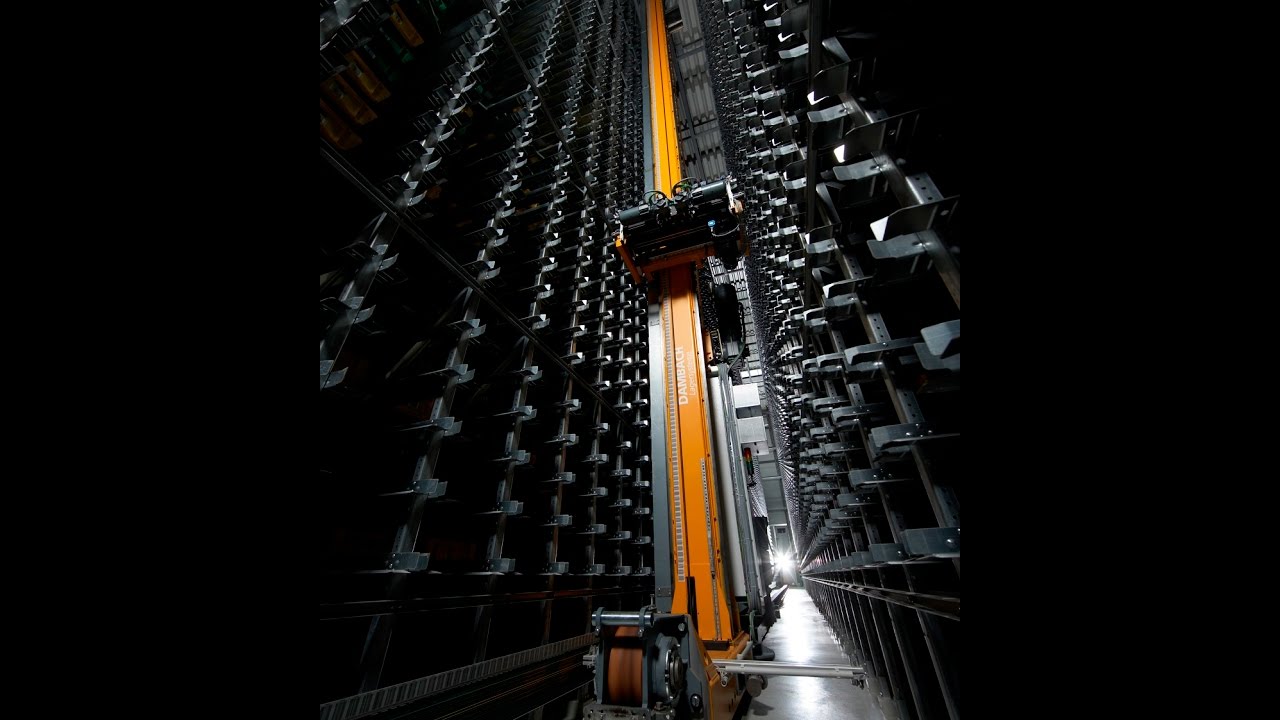

Dynamic Pouch Sorter with Buffer Functionality

At the heart of the solution is a dynamic pouch sorter featuring 8 buffer carousels. Products for multi-item orders are first loaded into pouches at 8 loading stations, where each pouch holds one item from a multi-item order. The sorter acts as a dynamic buffer, temporarily storing pouches until all items of a specific order are available. This addresses the challenge of staggered arrivals from different production areas, ensuring orders are only consolidated once complete. The pouch sorter’s overhead conveyor design maximizes vertical space utilization, a key advantage in the height-constrained existing warehouse.

Dematic Pouch Sorter System: Flexible Omnichannel Fulfillment

Vendor: Dematic

Key Features

The dynamic pouch sorter’s buffer functionality is a critical feature, allowing staggered items from disjointed production areas to be temporarily stored until full order completion. This eliminates the need for manual tracking and consolidation of partial orders, significantly reducing errors and delays.

The 3-stage matrix sorting system enables automatic, efficient consolidation of multi-item orders, ensuring that all items from a single order—even those from different production sites—are combined into one package. This enhances customer satisfaction by delivering a single shipment instead of multiple parcels.

The integrated lying goods conveyor technology creates a unified material flow for all order types and recipients, streamlining operations and reducing process complexity. Single-item orders are routed directly to shipping at 4,000 per hour, while multi-item orders proceed through consolidation, all using the same core conveyor infrastructure.

Pre- and Post-buffer modules optimize sorting performance by regulating pouch flow, preventing bottlenecks, and ensuring packing stations are utilized evenly. This design maximizes throughput while maintaining consistent processing speeds.

The 2-level overhead design of the pouch sorter exemplifies exceptional space efficiency, fitting within the existing warehouse’s limited height and footprint. By utilizing vertical space, the solution avoids the need for costly facility expansion while delivering significant capacity gains.

The system’s ability to process up to 2,500 order lines per hour and 4,000 single orders per hour makes it highly scalable, supporting CEWE’s growth objectives and handling increasing order volumes without compromising efficiency.

Results & Benefits

The primary成果 of the project is the automated consolidation of multi-item orders, ensuring that end customers, retailers, and sister companies receive a single package even when ordering multiple products from different sources. This has significantly improved customer satisfaction and reduced shipping costs associated with multiple parcels.

The system achieves impressive throughput metrics: up to 2,500 order lines per hour for multi-item orders and 4,000 single orders per hour routed directly to shipping. This represents a substantial increase in operational efficiency compared to manual or semi-automated processes.

By utilizing a 2-level overhead design, the solution maximized space utilization in the existing warehouse without requiring expansion. This space efficiency translates to cost savings and avoids the disruption of facility construction, allowing the project to be implemented within the current shipping area.

The unified material flow across all order types and recipients has streamlined operations, reducing process variability and inefficiencies. Employees benefit from consistent workflows regardless of the order complexity or destination, improving productivity and reducing training requirements.

The automation of sorting, buffering, and consolidation processes has increased overall order processing quality, minimizing errors and ensuring accurate order fulfillment. This has reduced returns and rework, further lowering operational costs and enhancing CEWE’s reputation for reliability.

Challenges & Solutions

CEWE’s primary challenge was consolidating time-staggered multi-item orders from disjointed production areas and sister companies, which previously required manual tracking and assembly. The solution was psb’s dynamic pouch sorter with buffer carousels and 3-stage matrix sorting, which automatically stores partial orders until complete and then consolidates items into cohesive shipments—eliminating manual intervention and reducing errors.

A second major challenge was implementing the solution within the existing warehouse’s limited height and footprint, with no room for expansion. psb addressed this by designing a 2-level overhead pouch sorter system that utilizes vertical space efficiently. The layout places workstations and sorting stages on the warehouse floor and the large pouch buffer directly above, maximizing space utilization without modifying the facility’s structure.

The third key challenge was unifying material flow for diverse order types (single vs. multi-item) and recipients (end customers, 20,000 retailers, 14 sister companies). The integrated lying goods conveyor technology solved this by creating a consistent workflow that handles all order and recipient combinations, ensuring efficient processing regardless of the shipment’s complexity or destination.

System Integrator

psb intralogistics served as the system integrator and solution provider for the project, delivering a turnkey intralogistics solution tailored to CEWE’s specific needs. The company designed and implemented the dynamic pouch sorter, 3-stage matrix sorting system, lying goods conveyor technology, and integrated control software (WES/WCS).

psb’s expertise in high-density, space-efficient sorting solutions was critical to addressing the project’s core constraints—limited warehouse space and height. The company’s patented Multi Access Warehouse technology and experience with pouch sorters enabled the development of a solution that maximizes throughput while fitting within the existing facility.

The successful implementation reflects psb’s ability to integrate multiple technologies into a cohesive system that addresses complex order consolidation challenges. By combining dynamic buffering, matrix sorting, and unified conveyor technology, psb delivered a solution that supports CEWE’s growth objectives, enhances operational efficiency, and improves customer satisfaction. The partnership between CEWE and psb demonstrates the value of tailored intralogistics solutions in addressing industry-specific challenges.

🖼️Project Gallery

🔧Related Technologies (6)

Dematic Pouch Sorter System: Flexible Omnichannel Fulfillment

byDematic

Pouch Sorter: Overhead Handling for Flat-Packed Items

bypsb intralogistics GmbH

Crossbelt Sorter: High-Availability Multifunctional Sorting

byInterroll

Peerless Clothing USA Apparel Distribution Warehouse

byElement Logic

BG Pouch System: Low-Touch Overhead Multi-Use Sortation

by BEUMER Group

LP Put Wall System (Put-to-Light): Order Consolidation and Sortation

byMatthews Automation Solutions

📚Related Knowledge Articles (3)

Overhead Conveyors

Overhead conveyors suspend products from tracks mounted above the work area, freeing floor space while transporting items through manufacturing, finishing, storage, and distribution processes.

Small Load Conveyors

Small load conveyors transport individual items, totes, cartons, and packages through warehouses and distribution centers using belt, roller, or slat systems optimized for lightweight products.

Pouch/Pocket Sorter

Pouch Sorters use suspended fabric pouches or pockets traveling on an overhead track to sort individual items with exceptional gentleness and flexibility. Ideal for fashion, apparel, and omnichannel retail operations, these systems excel at handling soft goods, hanging garments, and irregularly shaped items while providing dynamic buffering and sequencing capabilities.