Our Curated Projects

26 projects

The Feed Sports Nutrition Automated Fulfillment Center with Brightpick

An AI-powered e-commerce fulfillment center operated by 48 Brightpick Autopicker robots, processing 50,000 items daily with 24/7 operations for a leading sports nutrition retailer.

Landmark Group Kuwait Fulfillment Center

Landmark Group partnered with Addverb to modernize its Kuwait fulfillment center with robotic sorters and carton shuttles, achieving up to 1,000 sorts per hour for enhanced e-commerce operations.

Alza Prague High-Throughput Fulfillment Center

Alza, the largest Czech/Slovak online retailer, deployed a 300,000-bin, 580-robot AutoStore system integrated by Element Logic, achieving 75% faster picking and handling up to 260,000 daily orders.

DHL Supply Chain Greater Poland E-commerce Hub

DHL Supply Chain implemented its first AutoStore system in Poland, creating an e-commerce hub to flexibly meet client needs, marking a significant step in automation for the region.

Rohlik.cz Prague Fulfillment Center

Rohlik Group automated its Prague e-grocery fulfillment center with Brightpick Dispatcher robots for intelligent order consolidation and dispatch, smoothing daily picking volumes.

Kesko Helsinki Micro-Fulfillment Center (MFC)

Kesko deployed Finland's first grocery micro-fulfillment center featuring a Dematic AutoStore system in a chilled environment, doubling daily volumes and enabling 6-hour delivery.

Walmart - Next Generation Fulfillment Centers Automation

Walmart partnered with KNAPP to deploy next-generation fulfillment centers featuring Evo 2D Shuttle ASRS, doubling storage capacity and streamlining 12-step processes into 5 steps for omnichannel retail.

JD.com - Flexible Case Picking Automation with ForwardX Robotics AMRs

Global e-commerce leader JD.com partnered with ForwardX Robotics to deploy Max Series AMRs across its 1,600+ Chinese warehouses, optimizing case picking efficiency and reducing worker physical exertion.

International 3PL E-commerce Warehouse with RoboShuttle

A 3PL cross-border e-commerce warehouse utilizing Geekplus RoboShuttle, the industry's tallest mobile robot, achieving 500+ units per hour picking efficiency with maximum vertical space utilization.

Amway Midwest Regional Service Center, Ada

Amway streamlined its Midwest fulfillment, moving to a new automated facility 50% smaller yet capable of handling over 30,000 cartons daily, achieving faster order fulfillment and reduced costs.

Addverb 3PL Omnichannel Fulfillment Center

Addverb transformed a 330,000 sq. ft. 3PL facility with integrated fixed and flexible automation, enabling seamless B2B and B2C operations and a dispatch of 100,000 pieces daily.

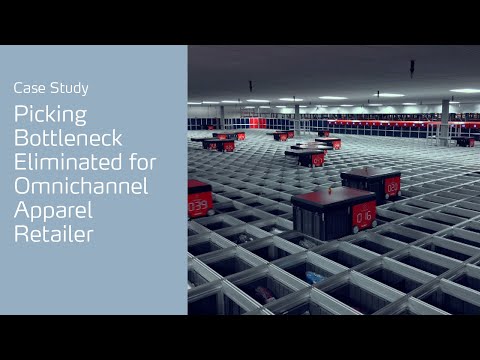

Carter's / OshKosh USA Distribution Center

The children's apparel brand boosted distribution efficiency with Element Logic's high-speed unit sortation technology, enabling precise handling of thousands of units for retail and e-commerce orders.

PUMA Indianapolis Pandemic-Resilient Distribution Center

PUMA's Indianapolis DC, opened on-time in June 2020 amidst the pandemic, provided critical capacity to handle surging e-commerce demand, acting as a 'beacon of hope' for future growth.

CNH Industrial Indianapolis Distribution Center

CNH Industrial partnered with Bastian Solutions to integrate AutoStore, conveyors, sortation cells, and WCS, optimizing their facility for same-day shipping and 24-48 hour fulfillment.