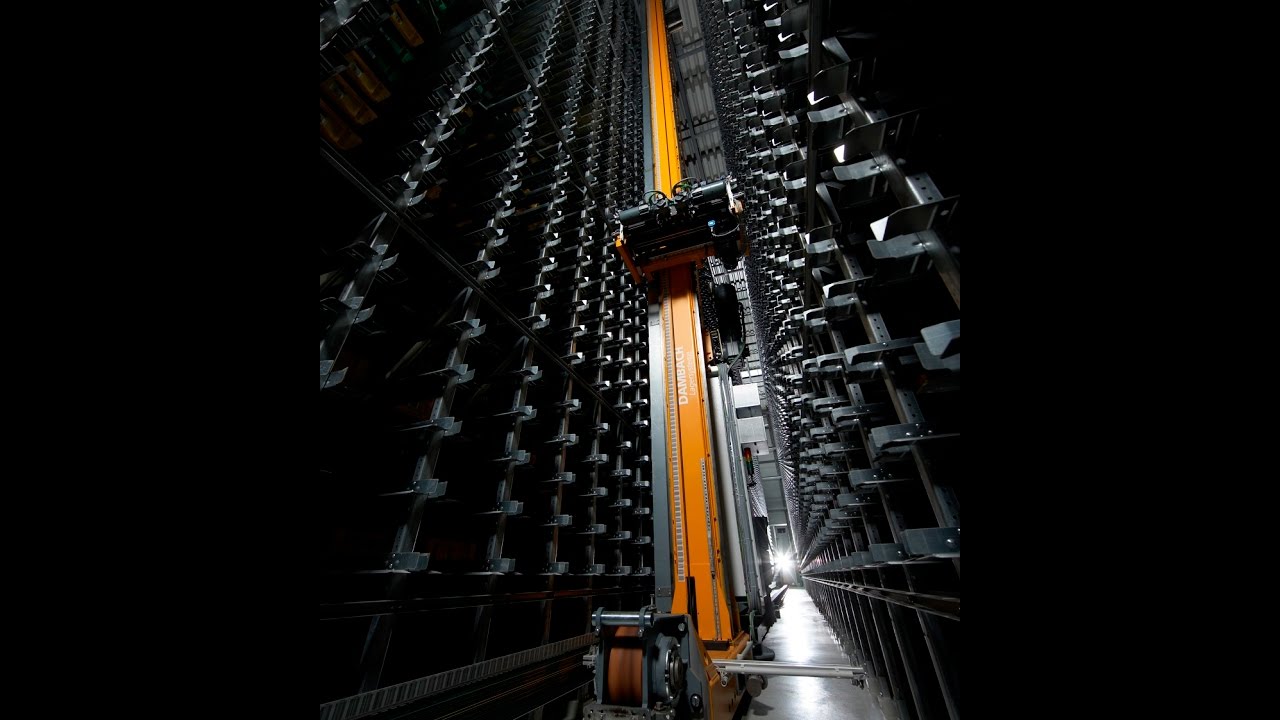

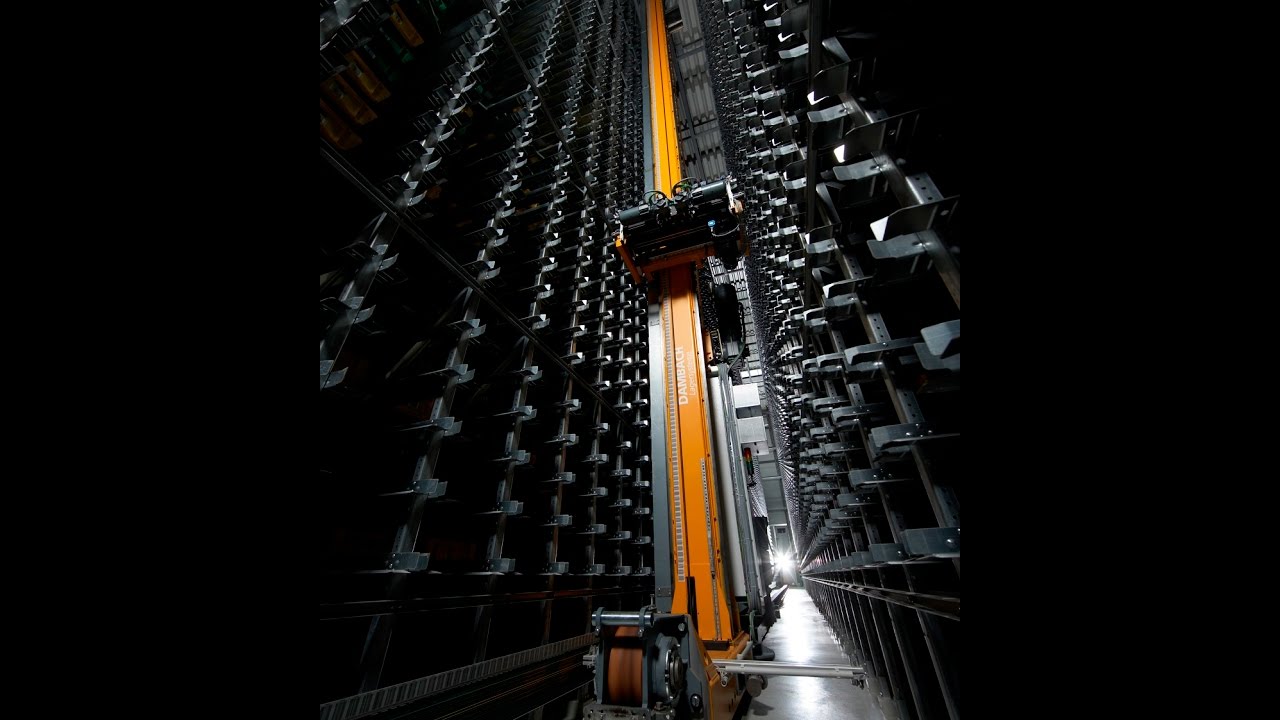

DAMBACH MULTI Series: Curve-Going, Aisle-Changing Stacker Crane

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

The DAMBACH MULTI series represents an innovative approach to automated storage and retrieval systems (AS/RS), moving beyond the traditional fixed-aisle stacker crane. It is a curve-going stacker crane designed with the flexibility to navigate through a networked rail system and change aisles via switch points. This core functionality allows multiple MULTI cranes to operate within the same storage grid, dynamically allocating themselves to aisles based on real-time demand. This design significantly enhances overall system availability and throughput. Engineered for robustness, it features a patented rail system to minimize wear and is capable of operating in demanding environments such as cold storage, making it a versatile solution for modern, high-performance warehouses.

How It Works

Core Principles

The system operates on the principle of a rail-guided stacker crane that is not confined to a single aisle. It travels on a network of straight and curved rails, using switch points (similar to railway points) to transfer between different aisles within the storage area upon command from the central control system.

Key Features & Capabilities

Dynamic Aisle Changing and Multi-Crane Operation is the transformative feature. Unlike fixed-aisle cranes, MULTI cranes can be dispatched to any aisle, allowing a smaller fleet to service a larger racking area with high redundancy. If one crane is under maintenance, others can cover its work.

Patented Rail Geometry and Dual-Driven Wheels are engineered for durability and precise maneuverability. The rail design reduces wear on wheels and tracks, while the two driven wheels provide the necessary traction and control for navigating curves and switch points reliably.

Integrated Control for Complex Environments combines the crane control and point switching logic into one system. This, coupled with a parameter-controlled strategy for multi-crane coordination, ensures safe, collision-free, and efficient operation of the entire fleet, even in harsh conditions like cold storage.

Advantages & Benefits

The primary advantage is dramatically increased system uptime and availability. The variable aisle allocation means there is no single point of failure for an aisle; tasks are dynamically rerouted to available cranes, making the system highly resilient.

It offers superior space utilization and layout flexibility. The ability to use curved aisles allows the system to fit into irregularly shaped buildings or around obstacles, maximizing storage density within the existing facility footprint.

Operational efficiency is optimized through better crane utilization. Cranes are not idle waiting for work in a dedicated aisle but can be shared across the warehouse, reducing the total number of cranes needed for a given throughput level and lowering long-term operational costs.

Implementation Considerations

System design and layout planning are highly complex. Engineering the rail network, switch point locations, and traffic flow patterns for multiple cranes requires sophisticated simulation and detailed planning to ensure performance goals are met.

The control software and safety systems are critical and complex. Implementing the parameter-based operating strategy for multi-crane coordination is non-trivial and requires deep integration with the warehouse control system to manage priorities and prevent deadlocks or collisions.

While offering flexibility, the initial investment for the specialized rail network, switch points, and advanced control system is likely higher than for a traditional fixed-aisle ASRS, necessitating a thorough analysis of the flexibility benefits versus cost.

Use Cases & Applications

Ideal For

This system is ideal for high-throughput distribution centers, production supply warehouses, and cold storage facilities where maximizing equipment uptime and operational flexibility is critical. It is especially valuable in sites with expanding or fluctuating storage needs.

Performance Metrics

While specific throughput numbers are not provided, the performance gain is qualitative and systemic: high availability due to variable aisle allocation and multi-crane operation. The key metrics are system uptime and task completion flexibility rather than a single crane's speed.

Conclusion

The DAMBACH MULTI series stacker crane system redefines flexibility in automated storage. By enabling cranes to change aisles, it solves traditional ASRS limitations related to dedicated equipment and fixed traffic patterns. For operations prioritizing system resilience, adaptability to non-rectangular spaces, and high utilization of automated equipment, the MULTI series offers a compelling and sophisticated solution. Implementing such a system requires a strong partnership with the provider for detailed design, simulation, and integration to fully harness its potential for creating a highly available and efficient warehouse backbone.

📦Related Projects

DAMBACH MINI-LOAD Automated Small Parts Storage System

The DAMBACH MINI-LOAD system is an automated storage and retrieval machine for small parts, achieving heights up to 27 meters and high throughput for container and carton storage.

LIEKEN High Bay Cold Store for Baked Goods

A high bay cold store for bread and baked goods with a capacity of 6,000 pallets at -24°C, using DAMBACH Storage and Retrieval Machines to achieve 4,296 pallet movements daily.

Dongfeng Motor R&D Center Smart Logistics Warehouse

A compact 470㎡ intelligent warehouse with 15-level high-density storage supporting 10,000+ SKUs for automotive R&D supply chain optimization.