LP Put Wall System (Put-to-Light): Order Consolidation and Sortation

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

The LP Put Wall system, offered by Matthews Automation Solutions under the Lightning Pick brand, is a put-to-light solution specifically designed for the order consolidation phase in modern fulfillment, particularly e-commerce. It addresses the challenge of efficiently sorting large batches of co-mingled items that have been pre-picked from warehouse zones into discrete, shippable customer orders. For two decades, such light-directed systems have formed a growing user community, proving their effectiveness in enhancing accuracy and throughput. The system often employs a two-sided wall design, physically separating the sorting (putting) and packing processes to optimize workflow and labor specialization, though it can also be configured for single-sided operation.

How It Works

Core Principles

The core principle is light-directed, scan-confirmed manual sortation. The system uses illuminated indicators at each order location (bin) to direct an operator where to place each scanned item from a mixed batch, creating an error-proofed process for assembling individual orders.

Key Features & Capabilities

The two-sided operational design is a key feature, enabling a clean division of labor where one side focuses on accurate sorting and the other on efficient packing, minimizing congestion. The integrated barcode scanning and light guidance creates a closed-loop, error-proofed process that ensures every item is correctly placed. The system's configurability in size (number of bins) and process flow (two-sided vs. one-sided) allows it to be tailored to specific operational volumes and layouts. The software capability to manage ancillary tasks like packing list insertion adds value by incorporating a typically separate step into the guided workflow.

Advantages & Benefits

The primary benefit is transforming a complex, error-prone manual sortation task into a simple, guided process, significantly increasing accuracy and speed in order consolidation. This is especially critical for e-commerce fulfillment where order accuracy directly impacts customer satisfaction. The system improves labor productivity by eliminating guesswork and search time, allowing operators to work faster and with less training. The two-decade proven track record and growing user community of the Lightning Pick platform provide assurance of reliability and continuous development.

Implementation Considerations

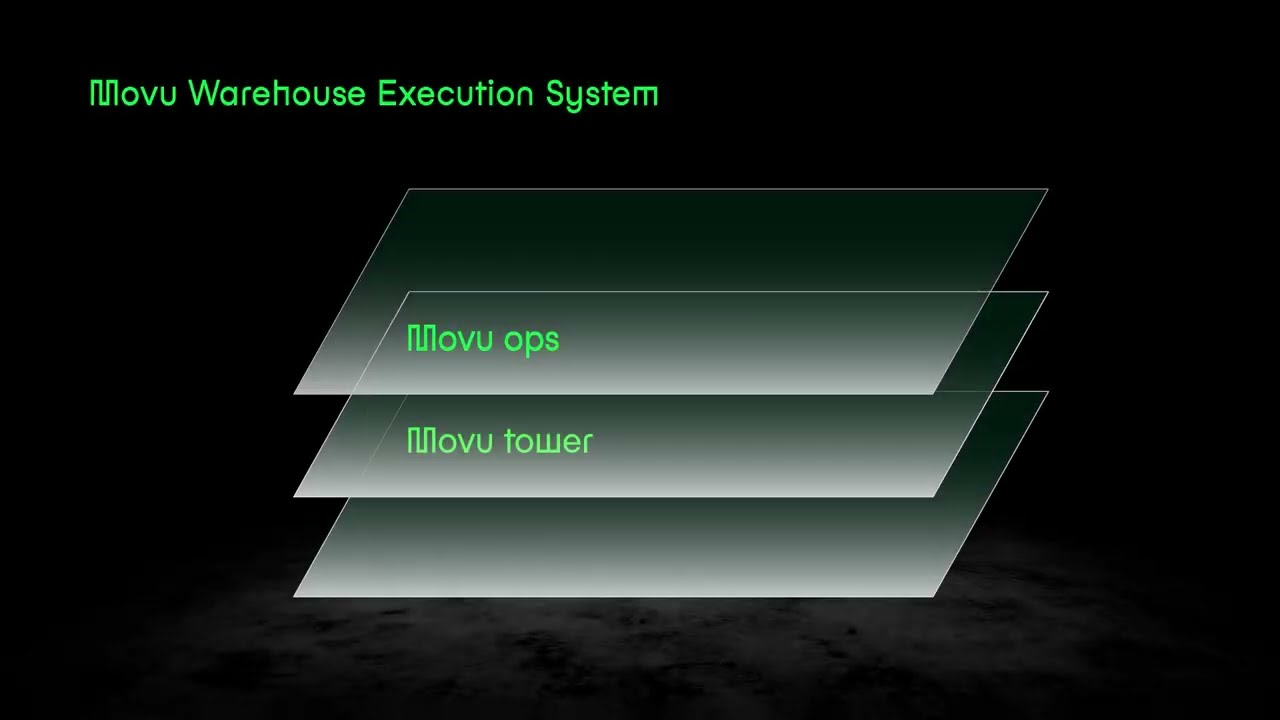

Implementing an LP Put system requires an effective upstream batch picking process to provide the co-mingled item batches. Integration with the host Warehouse Management System (WMS) or Warehouse Execution System (WES) is necessary to download order data and receive batch information. The choice between a two-sided or one-sided layout has implications for space utilization and labor organization. The number of put locations (bins) must be sized appropriately for the average number of concurrent orders being sorted to maintain flow without excessive walking for the operator.

Use Cases & Applications

Ideal For

This system is ideal for medium to high-volume e-commerce retailers, omnichannel fulfillment centers, and 3PLs that utilize batch or wave picking and need an efficient way to sort those batches into individual shipments.

Conclusion

The LP Put Wall system exemplifies a mature and highly effective application of light-directed technology to solve a fundamental challenge in e-commerce logistics. By providing clear, system-directed instructions, it brings order and efficiency to the chaotic task of sorting batch picks. Its flexibility in configuration and proven reliability make it a safe and valuable investment for operations looking to improve accuracy, throughput, and scalability in their order fulfillment process. For companies seeking a practical, technology-enhanced solution to order consolidation without the complexity of full automation, a put-to-light system like LP Put offers an excellent balance of performance, cost, and operational simplicity.