Automated Packaging System for Bars and Cakes

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

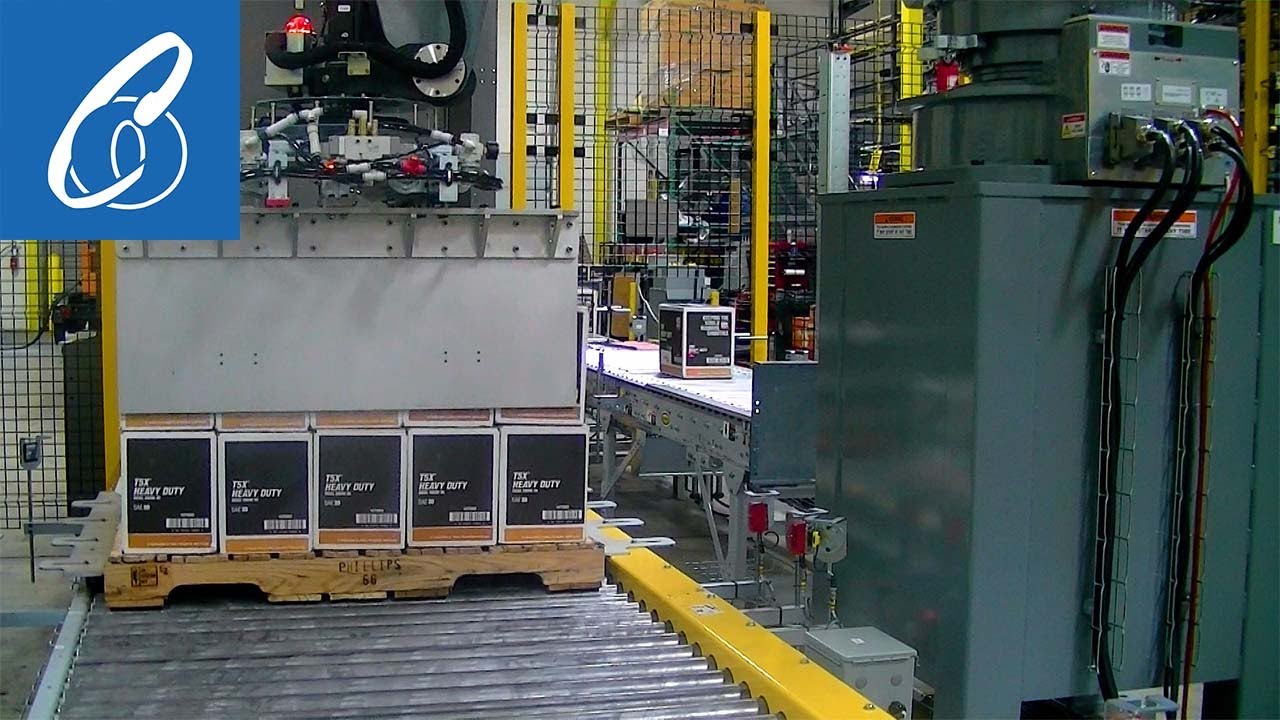

Technology Overview

This automated packaging system from Syntegon is a comprehensive, integrated line specifically engineered for the delicate handling and high-speed packaging of food products like chocolate bars and chocolate-coated cakes. It addresses the dual challenges of protecting fragile items from breakage while maximizing production throughput. By seamlessly linking multiple specialized machines—from primary wrapping to final case packing—the system creates a continuous, synchronized flow. This end-to-end automation is designed to replace manual or semi-automated stages, ensuring consistency, hygiene, and efficiency in demanding food manufacturing environments.

How It Works

Core Principles

The core principle is the creation of a fully integrated, sequential packaging line where each step—from individual product wrapping to bulk case packing—is automated and synchronized to maintain a constant flow, with gentle handling as a paramount concern throughout.

Key Features & Capabilities

The system's emphasis on gentle product handling is a critical feature, involving specialized conveyors and grippers to protect delicate items. The use of mono-material film in flow wrapping aligns with sustainable packaging goals, as such materials are often more easily recyclable. The integration of both traditional robotics and collaborative robots (cobots) allows for high-speed, precise handling in some stages and safe, flexible human-robot collaboration in others, like carton loading. The end-to-end integration ensuring constant flow minimizes bottlenecks and maximizes overall equipment effectiveness (OEE).

Advantages & Benefits

The primary benefit is the significant reduction in product breakage, which directly improves product quality, reduces waste, and increases yield. This gentle automation enables higher line speeds and output than would be possible with manual handling of fragile goods. The fully automated, constant flow minimizes labor requirements, improves consistency, and enhances production hygiene. The sustainable packaging option (mono-material film) helps manufacturers meet environmental targets and consumer preferences.

Implementation Considerations

This is a custom-integrated system designed for specific product types (bars, cakes), so flexibility for vastly different products may be limited. The integration of multiple machines from a single supplier (Syntegon) can simplify coordination and support. The line requires significant floor space and careful layout planning for material flow and maintenance access. As a fully automated food line, it must meet strict hygiene and safety standards. The total investment is substantial and must be justified by gains in output, quality, and labor savings.

Use Cases & Applications

Ideal For

This system is ideal for medium to large-scale confectionery, bakery, or snack food manufacturers producing fragile, uniform items like chocolate bars, granola bars, biscuits, or cakes that require individual wrapping and cartoning.

Conclusion

Syntegon's automated packaging system for bars and cakes represents a high-end, tailored solution for food manufacturers prioritizing product integrity, speed, and sustainability. By automating the entire process from wrapping to case packing with a focus on gentle handling, it solves key operational challenges in fragile goods packaging. For companies facing issues with breakage, labor-intensive processes, or throughput limitations, investing in such an integrated line can deliver substantial improvements in quality, efficiency, and overall profitability, while also supporting environmental packaging initiatives.