Our Curated Projects

53 projects

Van Meter - Cedar Rapids Electrical Distribution Warehouse Automation

Van Meter implemented 18 Kardex vertical lift modules and conveyor systems to automate electrical parts distribution, achieving 99.99% accuracy and supporting business growth goals.

KICKS - Rosersberg Beauty Products Automated Distribution Center

KICKS implemented KNAPP's automated solution with vertical push tray sorter and high-speed shuttles at its Rosersberg facility, improving store availability and scalability for 250+ Nordic beauty stores.

PUMA - Geiselwind Multi-Channel Automated Distribution Center

PUMA’s highly-automated distribution center in Geiselwind, Germany, uses TGW’s FlashPick® system (700,000 storage locations) to dispatch 74 million items/year with 10-minute order-to-issue time, serving retail and wholesale channels.

DPD Warszawa - Poland Logistics Center Parcel Sorting Automation

DPD Warszawa implemented BEUMER Group's BG Line Sorter at its Poland logistics center, delivering 1,500-10,000 items/hour throughput with active slat-belt technology for diverse parcel handling.

CEWE Stiftung - Oldenburg Production & Distribution Center Automation

psb intralogistics implemented a dynamic pouch sorter and lying goods conveyor system at CEWE Stiftung's Oldenburg facility, handling 2,500 order lines/hour and 4,000 single orders/hour to optimize multi-item order consolidation and shipping efficiency.

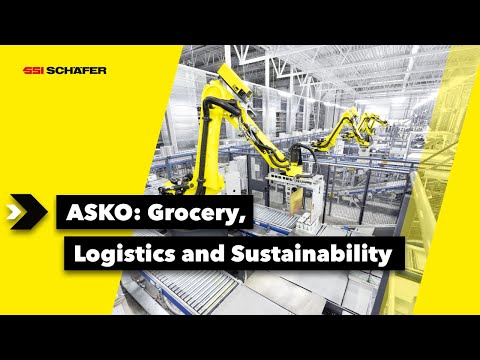

ASKO OSLOFJORD AS - Sustainable Automated Distribution Center

ASKO OSLOFJORD AS built a new sustainable automated distribution center by SSI Schaefer (80-90% process automation) to address capacity constraints, featuring heat reuse and a 2026 climate neutrality target.

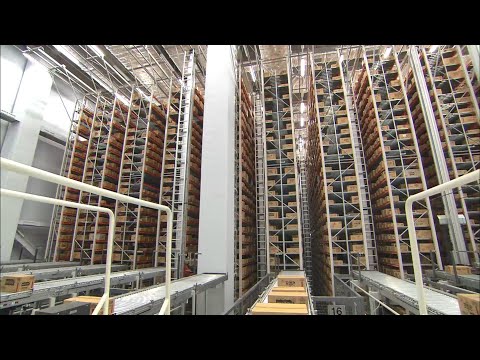

Lindab Automated Distribution Center

A 10,600 sqm automated distribution center with high-bay storage handling 250 pallets in/out per hour, featuring 21,500 pallet positions and achieving 50% productivity improvement.

ASKO Oslofjord Automated Distribution Center

ASKO proactively addressed capacity constraints with SSI Schaefer's automated DC solution, achieving 80-90% process automation with strong sustainability focus.

Weiling GmbH Coesfeld Distribution Center

A leading German organic food wholesaler implemented AutoStore system and high-bay warehouse to expand capacity and manage growing product range with flexible automation.

Ariat Wholesale Footwear & Apparel Order Fulfillment Center

A wholesale footwear and apparel brand automated order consolidation with the EuroSort Twin Push Tray Sorter, integrating Exotec and Geek+ robotic picking to process up to 16,000 items per hour.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

PUMA Indianapolis Pandemic-Resilient Distribution Center

PUMA's Indianapolis DC, opened on-time in June 2020 amidst the pandemic, provided critical capacity to handle surging e-commerce demand, acting as a 'beacon of hope' for future growth.

South West Healthcare Warrnambool Regional Logistics Distribution Centre

South West Healthcare deployed a Dematic AutoStore system to boost inventory capacity by 500% for its regional medical supply network, storing 6-8 weeks of stock in a reduced footprint.

Home Bargains Amesbury Distribution Center

Home Bargains implemented Lowpad's AMR solution with 91 robots to automate marshalling and process 200,000 roll cages weekly, addressing recruitment challenges in remote location.