Our Curated Projects

42 projects

SHAKE-HAND - Belgian Standard Elements Automated Storage

SHAKE-HAND implemented Kardex Miniload-in-a-Box systems including extended VBM units to replace manual storage, doubling capacity and reducing picking errors for machine builder distribution.

MRG - Retail Distribution Center Automated Goods-to-Person Intralogistics

MRG implemented an automated goods-to-person intralogistics solution by psb at its retail distribution center, featuring 6 rotapick systems and a 6,500-container Multi Access Warehouse to optimize small parts picking efficiency.

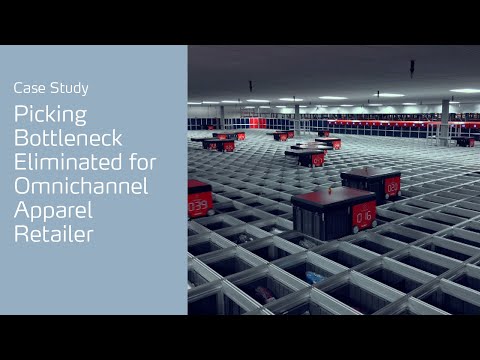

Cutter & Buck Seattle Apparel Fulfillment Center

Cutter & Buck deployed an AutoStore system with 34,000 bins and 54 robots, implemented by Kardex, to streamline apparel fulfillment, reduce storage footprint by 50%, and achieve order turnaround in under 10 minutes.

Kesko Helsinki Micro-Fulfillment Center (MFC)

Kesko deployed Finland's first grocery micro-fulfillment center featuring a Dematic AutoStore system in a chilled environment, doubling daily volumes and enabling 6-hour delivery.

Bruges Belgium FlashPick® Automated Warehouse System

TGW implemented a high-performance FlashPick® system in Bruges, Belgium, addressing double-digit annual growth, labor scarcity, and space constraints with modular, high-density automation.

Autumn Ocean Conveyor - Oakland Manufacturing Facility Omnichannel Fulfillment Automation

Autumn Ocean Conveyor's Oakland, Illinois manufacturing facility implemented Wind Right's Wind Soft solution with voice-directed technology and barcode scanners to automate inventory processes, improving accuracy and efficiency for omnichannel fulfillment.

Home Bargains Amesbury Distribution Center

Home Bargains implemented Lowpad's AMR solution with 91 robots to automate marshalling and process 200,000 roll cages weekly, addressing recruitment challenges in remote location.

Calzedonia Group Italian Distribution Center Pouch System

Calzedonia Group implemented BEUMER Group's BG Pouch System to expand fulfillment and returns capacity within its existing Italian distribution center, saving floor space with a ceiling-mounted design.

Amway Midwest Regional Service Center, Ada

Amway streamlined its Midwest fulfillment, moving to a new automated facility 50% smaller yet capable of handling over 30,000 cartons daily, achieving faster order fulfillment and reduced costs.

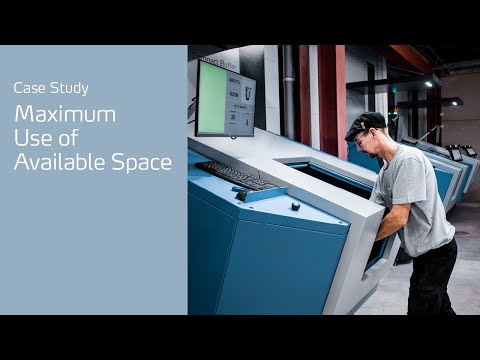

Gerrie Electric Ontario Distribution Center

Gerrie Electric implemented AutoStore with Bastian Solutions to transform their 26,000 sq ft facility, achieving 80-90 picks per person in 2 hours versus previous 7 hours.

PUMA - Geiselwind Multi-Channel Automated Distribution Center

PUMA’s highly-automated distribution center in Geiselwind, Germany, uses TGW’s FlashPick® system (700,000 storage locations) to dispatch 74 million items/year with 10-minute order-to-issue time, serving retail and wholesale channels.

L.L.Bean - Freeport Maine Distribution Center Sortation Modernization

L.L.Bean partnered with BEUMER Group to modernize its Freeport, Maine distribution center, converting from a two-pass to single-pass sortation system, boosting capacity from 18,000 to 37,000 units/hour for omnichannel order fulfillment.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Lao Gan Ma Guiyang Guizhou Production Warehouse

The iconic Chinese chili sauce brand automated its production logistics with a large-scale Unit Load AS/RS, palletizing robots, and STVs to connect 7 lines across 6 factories, achieving high inbound/outbound throughput.