Our Curated Projects

36 projects

JD.com - Flexible Case Picking Automation with ForwardX Robotics AMRs

Global e-commerce leader JD.com partnered with ForwardX Robotics to deploy Max Series AMRs across its 1,600+ Chinese warehouses, optimizing case picking efficiency and reducing worker physical exertion.

Autumn Ocean Conveyor - Oakland Manufacturing Facility Omnichannel Fulfillment Automation

Autumn Ocean Conveyor's Oakland, Illinois manufacturing facility implemented Wind Right's Wind Soft solution with voice-directed technology and barcode scanners to automate inventory processes, improving accuracy and efficiency for omnichannel fulfillment.

Rohlik.cz Prague Fulfillment Center

Rohlik Group automated its Prague e-grocery fulfillment center with Brightpick Dispatcher robots for intelligent order consolidation and dispatch, smoothing daily picking volumes.

Alza Prague High-Throughput Fulfillment Center

Alza, the largest Czech/Slovak online retailer, deployed a 300,000-bin, 580-robot AutoStore system integrated by Element Logic, achieving 75% faster picking and handling up to 260,000 daily orders.

The Feed Sports Nutrition Automated Fulfillment Center with Brightpick

An AI-powered e-commerce fulfillment center operated by 48 Brightpick Autopicker robots, processing 50,000 items daily with 24/7 operations for a leading sports nutrition retailer.

Element Logic Ireland Warehouse Automation Solutions

Element Logic Ireland provides smart, scalable warehouse automation solutions including robotic picking and high-density storage, tailored to the unique logistics challenges of the Irish market.

Sengkang General Hospital Singapore Central Sterile Supply Unit

A Singapore hospital transformed its surgical instrument logistics with a mini load AS/RS, vertical carousels, and robotic picking, integrated with barcode tracking and WMS/WCS to optimize the sterile supply flow.

X-step Smart Warehouse

X-step implemented Geek+ Robo shuttle tote-to-person picking solution to handle international expansion and seasonal demand fluctuations in sports apparel industry.

Lidl Køge Distribution Center

Lidl's distribution center in Køge, Denmark utilizes Vanderlande's automated case picking solution with ADAPTO shuttle-based AS/RS to outperform traditional order fulfillment methods.

Medline Industries Healthcare Distribution Center

First US deployment of Swisslog AutoStore system achieving 1,000 picks per hour per person, five times faster than traditional manual picking for healthcare supply distribution.

HiperDino - Telde Canary Islands Automated Warehouse with TGW Rovolution

Canary Islands-based HiperDino implemented TGW's FlashPick® and AI-powered Rovolution picking robot at its 50,000 m² Telde warehouse, handling 7,000 daily pallets and 5,000-10,000 tobacco cartons/day for 235 stores.

MRG - Retail Distribution Center Automated Goods-to-Person Intralogistics

MRG implemented an automated goods-to-person intralogistics solution by psb at its retail distribution center, featuring 6 rotapick systems and a 6,500-container Multi Access Warehouse to optimize small parts picking efficiency.

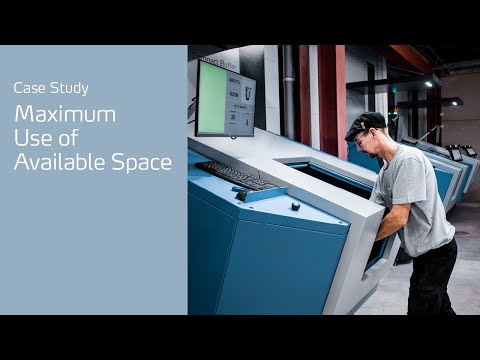

International 3PL E-commerce Warehouse with RoboShuttle

A 3PL cross-border e-commerce warehouse utilizing Geekplus RoboShuttle, the industry's tallest mobile robot, achieving 500+ units per hour picking efficiency with maximum vertical space utilization.

Knuspr Germany Micro Fulfillment Center

A leading German e-grocer automated post-pick order buffering, staging, consolidation, and dispatch using Brightpick Dispatcher robots in its micro-fulfillment center to drive down costs and enable 3-hour delivery.