Our Curated Projects

50 projects

Carter's / OshKosh USA Distribution Center

The children's apparel brand boosted distribution efficiency with Element Logic's high-speed unit sortation technology, enabling precise handling of thousands of units for retail and e-commerce orders.

L.L.Bean - Freeport Maine Distribution Center Sortation Modernization

L.L.Bean partnered with BEUMER Group to modernize its Freeport, Maine distribution center, converting from a two-pass to single-pass sortation system, boosting capacity from 18,000 to 37,000 units/hour for omnichannel order fulfillment.

Pitney Bowes Facility High Throughput Sortation

Pitney Bowes installed a EuroSort Single Split Tray (Bomb Bay) Sorter to maximize the number of sort destinations within a limited area, reducing manual touches and errors.

CNH Industrial Indianapolis Distribution Center

CNH Industrial partnered with Bastian Solutions to integrate AutoStore, conveyors, sortation cells, and WCS, optimizing their facility for same-day shipping and 24-48 hour fulfillment.

Agile Cold Storage Distribution Center

Third-party cold storage facility tripling pallet capacity to 48,000 in 110,000 sq ft using Swisslog ASRS with SynQ software, serving food manufacturers and global export markets.

San Francisco International Airport Harvey Milk Terminal 1 Baggage Handling System

SFO partnered with BEUMER Group to deploy the United States' first Individual Carrier System (ICS) baggage handling system, enhancing efficiency and security in the new terminal.

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Part of the Shinsei Project, this mega DC uses a Unit Load AS/RS, Shuttle Rack, palletizing robots, and RORO stations to handle 80 million beverage cases annually, ensuring stable supply for Osaka and Hyogo.

Roche Diagnostics Indianapolis Distribution Center

Roche Diagnostics transformed its distribution system with Bastian Solutions, achieving a 30% pack rate increase and 75% reduction in overtime spending.

SMC Corporation Indiana Distribution Center

A 1 million square foot distribution center featuring AutoStore goods-to-person system and pick-and-pass operation, doubling daily throughput and enabling 93% same-day shipping.

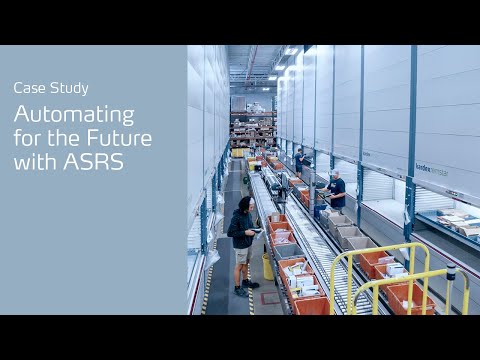

Van Meter - Cedar Rapids Electrical Distribution Warehouse Automation

Van Meter implemented 18 Kardex vertical lift modules and conveyor systems to automate electrical parts distribution, achieving 99.99% accuracy and supporting business growth goals.

Notions Marketing Distribution Center with Dematic CMMS - Grand Rapids

A 75-year-old distribution company transformed maintenance operations with Dematic CMMS, reducing reactive repairs by 50% while managing extensive conveyor and sorter networks for big-box retail fulfillment.

Sengkang General Hospital Singapore Central Sterile Supply Unit

A Singapore hospital transformed its surgical instrument logistics with a mini load AS/RS, vertical carousels, and robotic picking, integrated with barcode tracking and WMS/WCS to optimize the sterile supply flow.

Walmart - Next Generation Fulfillment Centers Automation

Walmart partnered with KNAPP to deploy next-generation fulfillment centers featuring Evo 2D Shuttle ASRS, doubling storage capacity and streamlining 12-step processes into 5 steps for omnichannel retail.

SHAKE-HAND - Belgian Standard Elements Automated Storage

SHAKE-HAND implemented Kardex Miniload-in-a-Box systems including extended VBM units to replace manual storage, doubling capacity and reducing picking errors for machine builder distribution.