AGV Unit Load

AGV unit load vehicles are automated guided vehicles designed to transport individual pallets, containers, or large items along fixed routes, providing reliable, predictable material movement in warehouses and manufacturing facilities.

AGV - Unit Load Overview

System Features

- •Autonomous OperationNo human driver

- •Heavy Load Capacity500-5,000+ lbs

- •24/7 OperationContinuous unmanned

- •Safety SystemsCollision avoidance

Navigation Types

- •Magnetic TapeFloor-mounted guidance

- •Laser NavigationReflective targets

- •Natural FeaturesNo infrastructure

- •Vision-BasedCamera and AI

Applications

- •ManufacturingProduction line supply

- •Warehouse DistributionPallet transport

- •Cold StorageTemperature-rated

- •Cross-DockingFlow-through ops

Key Benefits

- •Labor Reduction1-3 operators per AGV

- •Improved SafetyFewer accidents

- •Consistent PerformancePredictable operations

- •ScalableAdd vehicles as needed

Load Handling

- •Fork-StyleIntegrated forks

- •Conveyor-TopAuto transfer

- •TuggerPull carts/trailers

- •Lift-DeckPlatform lift

Future Trends

- •AI OptimizationSelf-learning routes

- •Enhanced AutonomyLess infrastructure

- •Fleet InteroperabilityMulti-vendor support

- •Predictive MaintenanceAI-powered

How AGV Unit Load Works

Unit load AGVs follow fixed routes defined by various guidance technologies. Traditional systems use magnetic tape, wire guidance, or optical line following that tracks painted lines on the floor, providing reliable navigation along predetermined paths. More advanced systems employ laser triangulation, using onboard lasers to measure distances to reflective targets positioned throughout the facility, enabling more flexible route modifications without floor infrastructure changes. The newest systems use natural feature navigation, relying on cameras and AI to recognize facility features like walls, columns, and equipment, eliminating the need for any installed guidance infrastructure.

The vehicle's load handling mechanism varies based on application requirements. Roller deck AGVs feature powered rollers that accept loads from conveyors or transfer stations, then discharge them at destinations using gravity or powered transfer. Lift deck vehicles raise and lower their platforms to pick up and deposit loads at floor level or on stands. Fork-style AGVs incorporate lifting forks similar to forklifts, enabling them to retrieve and deposit pallets in racking or on the floor. Each mechanism is optimized for specific load types, transfer methods, and facility layouts.

Route programming defines the AGV's operational behavior, including pickup locations, delivery destinations, travel paths, speeds, and safety zones. The fleet management system coordinates multiple vehicles, optimizing task assignments, managing traffic at intersections, preventing collisions, and ensuring efficient utilization across the fleet. Advanced systems use predictive algorithms to anticipate congestion and proactively adjust routes or timing to maintain smooth flow.

Key Benefits

The primary advantage of unit load AGVs is operational consistency. Unlike human operators who may vary in speed, accuracy, or availability, AGVs execute tasks identically every time, following precise routes at controlled speeds and positioning loads with millimeter accuracy. This predictability enables better production planning, inventory management, and quality control, as materials arrive exactly when and where needed without variation.

Labor cost reduction represents a major benefit, particularly in multi-shift operations. A single AGV can replace 2-3 forklift operators across shifts, delivering rapid return on investment while eliminating ongoing labor costs, benefits, and turnover expenses. The savings compound in facilities with high material movement volumes or those facing labor shortages and rising wage pressures.

Safety improvements result from removing human-operated forklifts from busy traffic areas. AGVs include comprehensive safety systems—typically laser scanners, ultrasonic sensors, safety bumpers, and emergency stop capabilities—that detect obstacles and people in their path, automatically slowing or stopping to prevent collisions. This reduces accident risks, particularly in facilities with mixed pedestrian and vehicle traffic or congested work areas.

Integration capabilities enable AGVs to work seamlessly with automated storage systems, conveyors, and production equipment. The precise positioning and timing control allow AGVs to interface directly with AS/RS systems, automated loading docks, or manufacturing cells, creating fully automated material flow without manual intervention. This integration is difficult or impossible to achieve reliably with human-operated equipment.

Common Applications

Unit load AGVs excel in several operational contexts. Warehouse putaway and retrieval uses AGVs to transport pallets from receiving docks to storage locations and later retrieve them for order fulfillment. The automated transport eliminates forklift traffic in storage aisles while maintaining precise inventory tracking through integration with warehouse management systems.

Production line feeding employs AGVs to deliver raw materials, components, or subassemblies to manufacturing workstations on demand. The just-in-time delivery reduces work-in-process inventory while ensuring that production lines never run short of needed materials. The predictable timing enables better production scheduling and resource planning.

Finished goods movement in manufacturing facilities uses AGVs to transport completed products from production lines to quality control, packaging, or shipping areas. The automated transport ensures smooth flow without production workers needing to manage material movement, allowing them to focus on manufacturing tasks.

Cross-docking operations leverage AGVs to move goods from receiving to shipping without intermediate storage, reducing handling time and labor costs. The automated transport maintains the rapid throughput that cross-docking operations require while providing precise tracking and routing capabilities.

Implementation Considerations

Successfully deploying unit load AGVs requires careful planning across multiple dimensions. Route design is critical—paths should minimize travel distance while providing adequate clearance, avoiding congestion points, and enabling efficient traffic flow. Routes must account for the AGV's dimensions, turning radius, and acceleration characteristics to ensure safe, efficient operation.

Infrastructure requirements vary by guidance technology. Magnetic tape or wire systems require floor preparation and installation, while laser navigation needs reflective targets positioned with clear sight lines. Natural feature navigation systems require stable facility features and adequate lighting. All systems need smooth, level floors free from debris, damage, or significant grade changes that could affect navigation or load stability.

Load standardization ensures compatibility across the system. Pallets, containers, or totes should have consistent dimensions, weight distributions, and bottom configurations to enable reliable pickup and delivery. Many operations invest in standardized load carriers optimized for AGV handling rather than adapting to diverse existing containers.

Traffic management becomes important in facilities with multiple AGVs or mixed vehicle types. The control system must coordinate vehicle movements to prevent conflicts at intersections, manage access to shared resources like elevators or transfer stations, and optimize overall fleet efficiency. Advanced systems use simulation and predictive algorithms to identify potential conflicts and adjust routes proactively.

Best Practices

To maximize unit load AGV effectiveness, consider these proven strategies. Demand-responsive operation dispatches AGVs based on real-time needs rather than fixed schedules, improving responsiveness while reducing unnecessary trips. The fleet management system monitors task queues and dynamically assigns vehicles to optimize utilization and minimize wait times.

Predictive maintenance uses vehicle telemetry and performance data to identify potential issues before they cause failures. Monitoring metrics like battery health, motor performance, sensor accuracy, and navigation precision enables proactive maintenance that minimizes downtime and extends equipment lifespan.

Staged deployment allows operations to validate system performance and refine processes before scaling to full capacity. Starting with a subset of routes or lower volumes provides valuable learning opportunities and reduces implementation risk, enabling adjustments before committing to full-scale deployment.

Mixed fleet strategies combine AGVs with other material handling equipment to optimize overall operations. AGVs handle predictable, high-volume flows along fixed routes, while forklifts or other equipment manage variable, lower-volume movements or serve locations unsuitable for AGV operation.

Technology Evolution

Modern unit load AGVs incorporate several advanced capabilities. Automatic load transfer systems enable AGVs to pick up and deposit loads without human intervention, using powered rollers, lift mechanisms, or fork systems that interface with conveyors, stands, or floor positions. This automation enables fully lights-out operations in some facilities.

Fleet optimization software continuously improves AGV operations through simulation, machine learning, and real-time analytics. These systems identify opportunities to reduce travel distance, improve utilization, and prevent congestion, often delivering 10-20% efficiency improvements after initial deployment.

Hybrid power systems combine battery operation with opportunity charging or battery swapping to enable continuous operation. Some systems use inductive charging at designated locations, automatically recharging batteries during brief stops without requiring manual intervention or battery changes.

Measuring Success

Key performance indicators for unit load AGV systems include loads moved per hour, vehicle utilization rates, on-time delivery performance, and system uptime. These metrics help assess whether AGVs meet operational requirements and identify optimization opportunities.

Return on investment typically materializes over 2-4 years through labor savings, improved material flow efficiency, and reduced accident costs. The predictable operating costs and long equipment lifespan—often 10-15 years with proper maintenance—create favorable long-term economics that justify the initial capital investment.

Safety performance should show measurable improvements compared to manual forklift operations, with reduced accident rates, severity, and near-miss incidents. Monitoring safety system activations helps identify areas where route design, traffic management, or safety parameters could be improved.

By implementing unit load AGVs with careful attention to route design, infrastructure requirements, and operational integration, facilities can create efficient, reliable material transport systems that reduce labor costs, improve safety, and enable more predictable operations. The technology's proven track record and continuous evolution ensure it remains a valuable tool for automated material movement in modern warehouses and manufacturing facilities.

🔧Related Technologies (6)

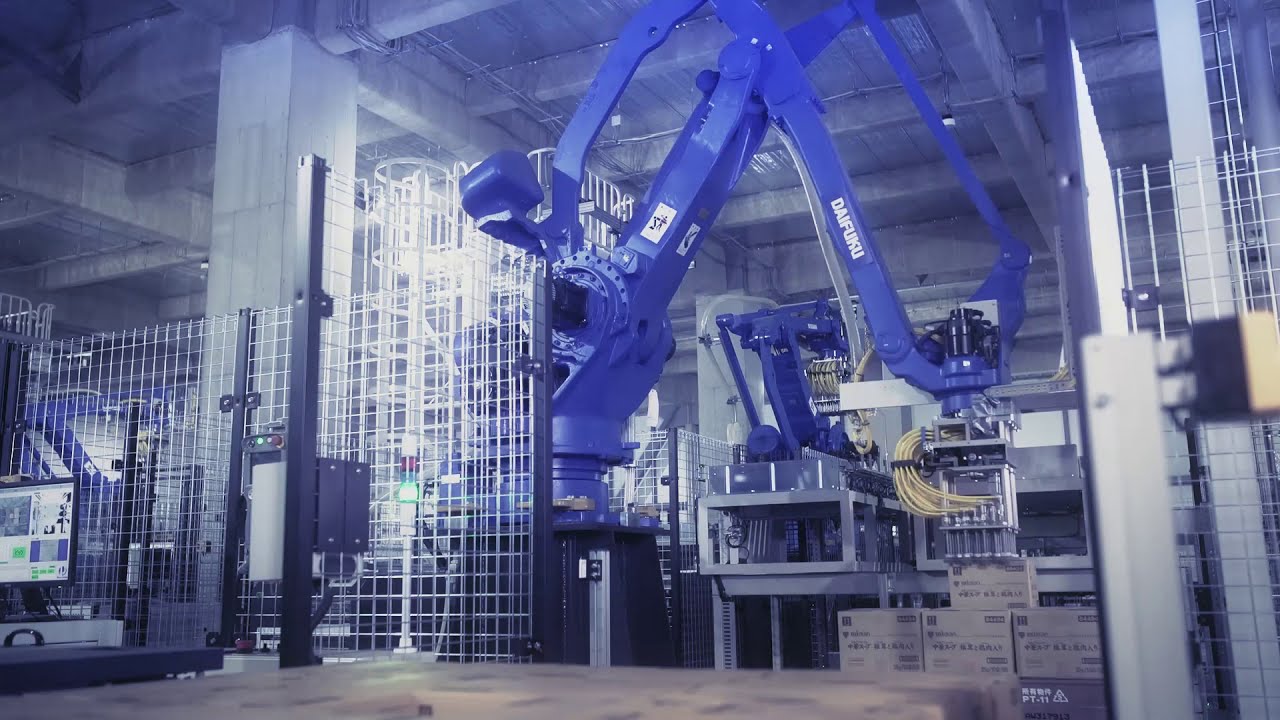

Piolax Canton Georgia Automotive Parts Distribution Center

byDaifuku

Meyer Corporation USA Cookware Distribution Center

byDaifuku

Side Loading & Unloading AGV: Strategic Partnership Announcement

byAncra Systems

Truck Loading and Unloading AGV: Automated Trailer Handling

by Ancra Systems

Laser-Guided Vehicles (LGVs) for Automated Truck Loading and Unloading

byOthers

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

📚Related Transport Topics

About This Topic

📁Related Projects(6)

Coca-Cola Bottlers Japan Akashi Mega Distribution Center

Daifuku

Deli Group Ninghai Intelligent Logistics Center

Daifuku

Lao Gan Ma Guiyang Guizhou Production Warehouse

Daifuku

F-Line Japan Major Food Distribution Center

Daifuku

Sengkang General Hospital Singapore Central Sterile Supply Unit

Daifuku

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions

🏢Related Suppliers(3)

6 River Systems

The Seamless Fulfillment Automation Solution to Boost Efficiency and Productivity in Your Warehouse

Addverb

Warehouse Automation that delivers value!

Ancra Systems

Efficient Loading