XP-R Mobile Racking System: High-Density Pallet Storage

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

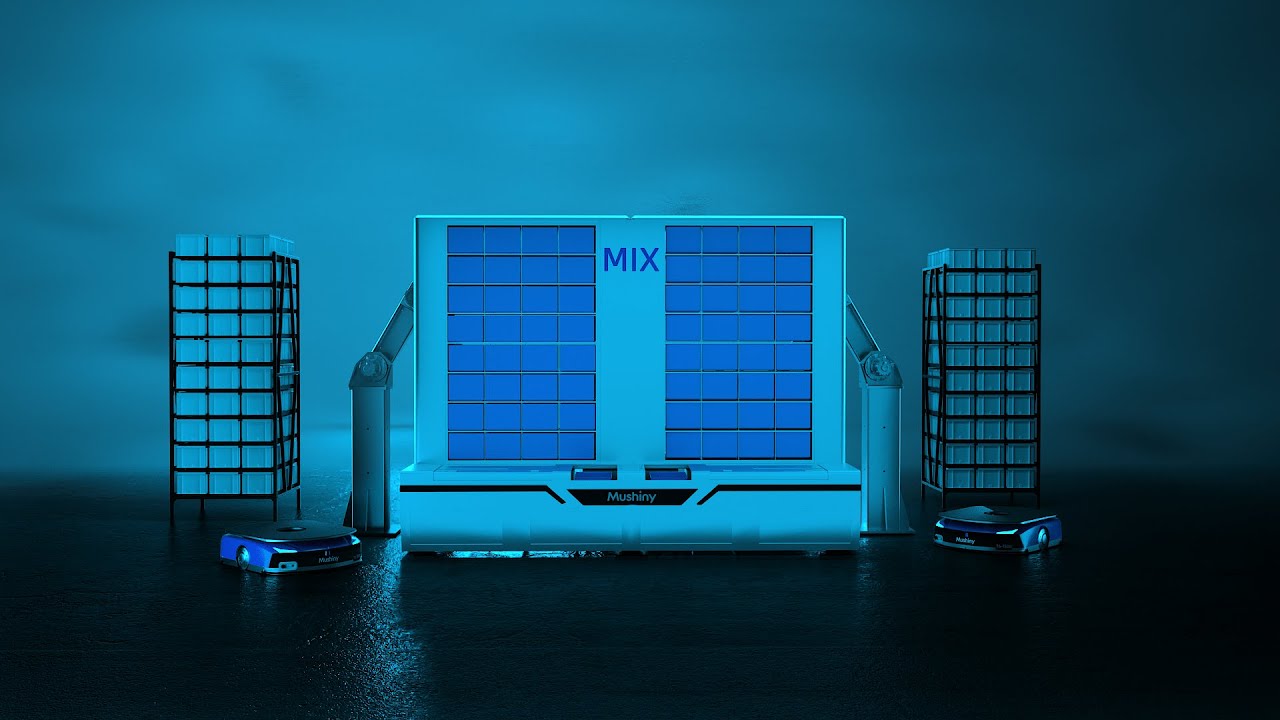

Technology Overview

The XP-R Mobile racking system by WDX is a high-density storage solution that addresses the universal challenge of maximizing pallet storage within a limited warehouse footprint. It represents a significant step up in space efficiency from conventional static racking. The system transforms fixed aisles into dynamic space by mounting entire rows of pallet racking onto mobile bases that glide on rails. This ingenious design allows an entire warehouse block to be condensed, with only a single access aisle required at any given moment. It is particularly recommended for facilities where the optimal use of every square meter of floor space is the paramount concern, offering a dramatic increase in storage capacity while still providing direct access to each pallet.

How It Works

Core Principles

The system operates on the principle of movable racking aisles. Instead of having multiple permanent aisles between static racks, the racks themselves move laterally on rails. An aisle is created only where and when needed by moving adjacent rack rows apart.

Key Features & Capabilities

Electrically Powered Mobile Bases enable smooth and reliable movement of heavy, loaded racking rows. High-Density Configuration is the core capability, with the potential to double storage capacity in the same floor area by eliminating most aisles. Direct Pallet Access is maintained, meaning every pallet remains individually accessible (unlike deep-lane systems), though not simultaneously. Single Aisle Operation dramatically increases storage density by reducing the total aisle footprint to a minimum.

Advantages & Benefits

The most compelling benefit is the massive increase in storage density, potentially doubling pallet count compared to conventional racking layouts. This leads to superior utilization of expensive warehouse real estate and can delay or eliminate the need for facility expansion. Unlike drive-in systems, it preserves selectivity and direct access to every pallet position. It is ideally suited for optimizing the entire floor surface of a warehouse, making it a top choice for space-critical applications.

Implementation Considerations

Implementing a mobile racking system requires a structurally sound and perfectly level floor capable of supporting the dynamic loads of moving racks full of inventory. The initial capital investment is higher than for static systems. Operational workflow must account for the brief time required to open and close aisles. Safety systems are crucial to protect personnel and equipment during movement. Adequate electrical supply must be planned for the drive motors.

Use Cases & Applications

Ideal For

This system is ideal for any warehouse or archive where storage density is the overriding priority, but maintaining direct access to all stored items (even if not simultaneously) is still required.

Conclusion

The WDX XP-R Mobile racking system presents a highly effective solution for warehouses seeking to radically increase their storage capacity without expanding their footprint. By intelligently moving racking rows to create aisles on demand, it achieves density levels that can double those of conventional systems. While the investment and floor requirements are significant, the payoff in space optimization is substantial. For operations where maximizing pallet count per square meter is critical and direct access to all inventory is still necessary, the XP-R Mobile system offers a powerful and efficient mechanized storage solution.